Midnight Oil

Enlightened

Hello, all.

This thread welcomes all design improvement suggestions for any flashlight body, from head to tail.

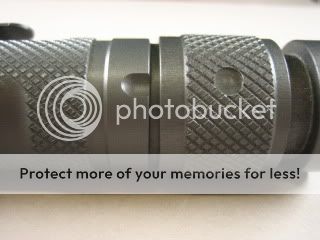

My first candidates are the Dereelight DBS V3 and CL1H V4 hosts. Here are my humble suggestions, very subjective of course. Please feel free to comment and add your own.

This thread welcomes all design improvement suggestions for any flashlight body, from head to tail.

My first candidates are the Dereelight DBS V3 and CL1H V4 hosts. Here are my humble suggestions, very subjective of course. Please feel free to comment and add your own.

- Thicker threads all around. Maybe even trapezoidal threads like on the Fenixes?

- Increase the length of the body and tailcap and recess the tailcap spring, so that the threads can engage at least one revolution of the tailcap before the spring presses on the end of the battery.

- Related to suggestion 2 above...locate the double o-rings at all joints so that the parts don't slide over the o-rings until the parts are 2 or 3 revolutions from being fully tightened. This will allow the parts to screw together much more easily. As it is, I've had to remove one o-ring from each joint of my CL1H. The tailcap was especially difficult to install before, even with lube, because the friction against the o-rings and the compression from the spring against the battery were making it hard to mate the threads.

- Instead of double o-rings, consider providing one thicker o-ring. The thinner double o-ring appears to have durability issues.

- Redesign the clip and ditch those screws! They just don't look right on a light with such good lines. Go with a simple clip that slides over the tailend and is clamped between the body and the tailcap. Consider including a lanyard hole on the clip.

- Offer option of a cigar grip and lanyard ring, both interchangeable with the clip.

- More aggressive knurling on the body and tailcap and a longer section of knurling on the body.

- As some P60 drop-ins don't fit well and their pills do not make consistent contact with the body, redesign the neck to allow for the use of an external spring on drop-ins.

- Offer option of either a tail-stand tailcap or tactical tailcap. For the tactical tailcap, the switch should protrude more.

- In the case of the CL1H, the flared neck and the body should be in one piece, unless the intent is to allow fitment onto the CL1H of a different head, like that of the DBS.

- Greater tolerance for differing lengths of P60 modules, so that the headcap can screw all the way down to the body. This goes hand in hand with allowing for outer spring on drop-ins.

- Reconsider O-ring and retaining ring design for the lens. Perhaps, adopt a design similar to that of the Surefire 6P.

- Tighter inner diameter for housing 18mm cells.

- Offer a sleeve accessory for housing CR123As so they don't rattle.

Last edited: