PCC

Flashlight Enthusiast

I've been asked to assemble a triple XP-G R5 with a Carclo triple optic. The request is for a copper heatsink but I needed to make a prototype out of aluminum as aluminum is much easier to machine and is much cheaper if I make a mistake. I don't have any dimensions of the cavity where this is going so I wanted to put something together to make sure that I can get at least in the ball park on certain dimensions. I want the unit to make contact with the inside walls of the host to allow the heat to transfer out to the atmosphere better. Here are some pictures of the prototype:

Despite the length, the bezel screws all the way down and only leaves a small gap about the thickness of a business card. It's going to be used in a SureFire 9P using three IMR 16340 cells and an Oveready Zero Tolerance unit in a Z41 tailcap. We'll have to see if the XP-Gs can handle this. I suppose that I could always mill out a pocket for a 17mm driver if it came to it. Unfortunately, the board that the XP-Gs are mounted to are wired 3S, complicating matters.

I'll post more as this project progresses.

Update on 10/31/2010

I finally decided to get off my lazy behind and work on this some more yesterday.

Cutting a piece of copper by hand. It's 1.375" in diameter as the copper that I had ordered for this project was the wrong diameter (too small).

The copper blank and the aluminum prototype. Since copper is expensive I should have cut it about 1/4" shorter. Oh, well.

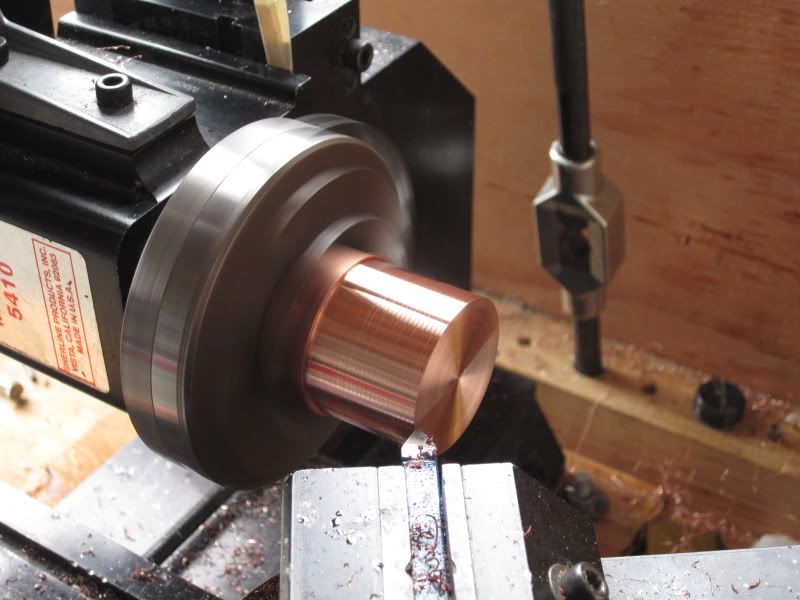

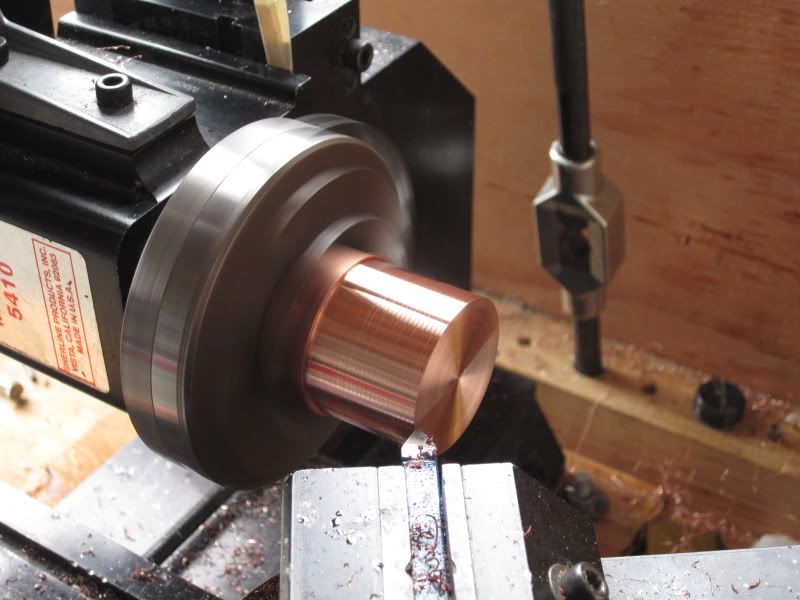

Cleaned up the saw marks and started reducing the diameter of the slug on the mill configured as a lathe.

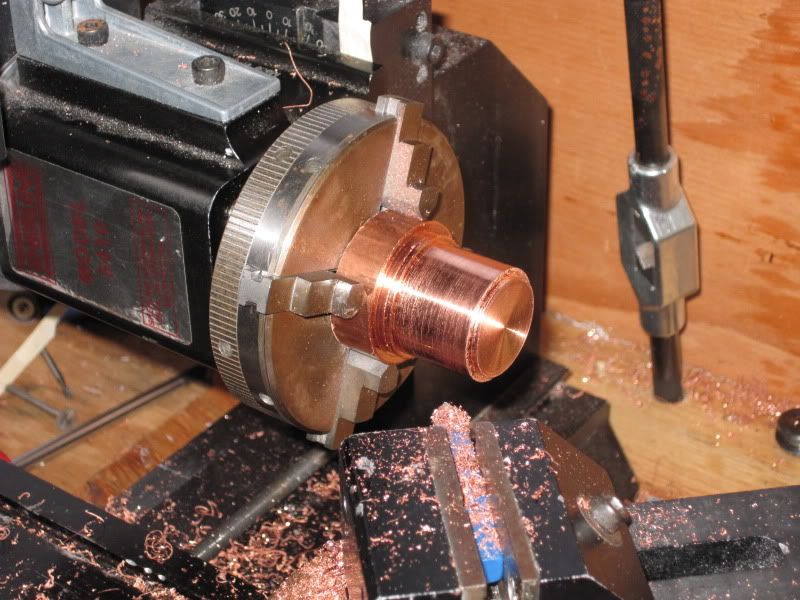

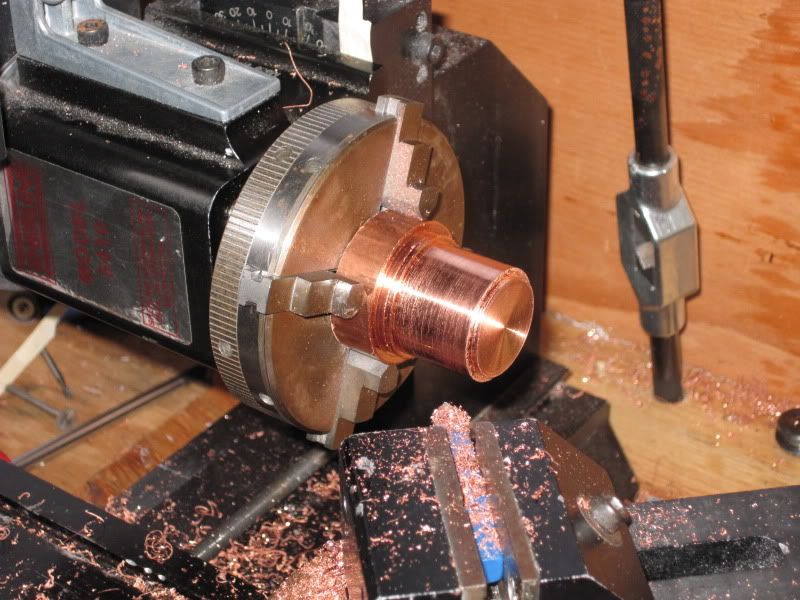

Cut down to about 27.3mm diameter, cut the step for the end of the bezel. The four-jaw chuck is then removed from the headstock and the mill reconfigured from lathe mode to mill mode and a pocket for the 3XP-G board cut.

This is as far as I got yesterday.

I think I spent about 4 hours on it to get to this point. The copper slug got really hot while working it even with cutting oil used as a lubricant so I had to let it cool for half an hour a few times.

I still need to flip the slug over and cut the other side. Stay tuned...

Despite the length, the bezel screws all the way down and only leaves a small gap about the thickness of a business card. It's going to be used in a SureFire 9P using three IMR 16340 cells and an Oveready Zero Tolerance unit in a Z41 tailcap. We'll have to see if the XP-Gs can handle this. I suppose that I could always mill out a pocket for a 17mm driver if it came to it. Unfortunately, the board that the XP-Gs are mounted to are wired 3S, complicating matters.

I'll post more as this project progresses.

Update on 10/31/2010

I finally decided to get off my lazy behind and work on this some more yesterday.

Cutting a piece of copper by hand. It's 1.375" in diameter as the copper that I had ordered for this project was the wrong diameter (too small).

The copper blank and the aluminum prototype. Since copper is expensive I should have cut it about 1/4" shorter. Oh, well.

Cleaned up the saw marks and started reducing the diameter of the slug on the mill configured as a lathe.

Cut down to about 27.3mm diameter, cut the step for the end of the bezel. The four-jaw chuck is then removed from the headstock and the mill reconfigured from lathe mode to mill mode and a pocket for the 3XP-G board cut.

This is as far as I got yesterday.

I think I spent about 4 hours on it to get to this point. The copper slug got really hot while working it even with cutting oil used as a lubricant so I had to let it cool for half an hour a few times.

I still need to flip the slug over and cut the other side. Stay tuned...

Last edited: