LightSward

Flashlight Enthusiast

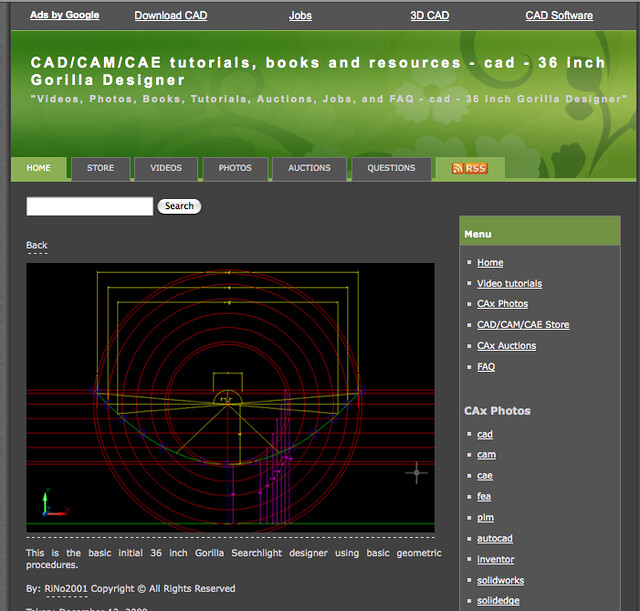

As expected, I learned a lot of things building the: 24" LightSward, 36" Gorilla, 50" Monster and the mini-LightSward.

With the invaluable experience gained working on the other light designs I will make a powerful, convenient and lightweight, 700-1200 watt/HMI light! :naughty: The final product will have a lightweight, water-resistant, Uni-body/Reflector housing for greater strength, agility convenience, and superior optical precision resulting in a long reaching beam.:thumbsup:

:naughty: The final product will have a lightweight, water-resistant, Uni-body/Reflector housing for greater strength, agility convenience, and superior optical precision resulting in a long reaching beam.:thumbsup:

The searchlight will be known as the: 26" LightSport.

With the invaluable experience gained working on the other light designs I will make a powerful, convenient and lightweight, 700-1200 watt/HMI light!

The searchlight will be known as the: 26" LightSport.

Last edited: