JohnnyLunar

Newly Enlightened

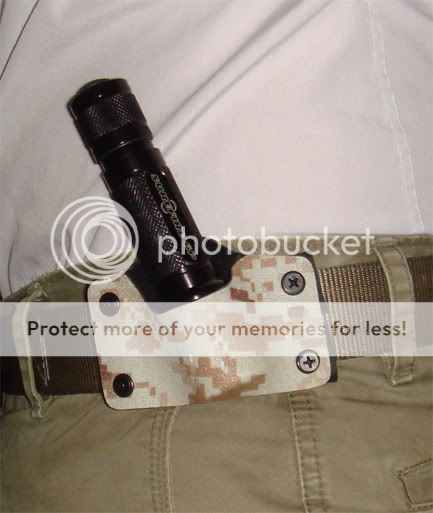

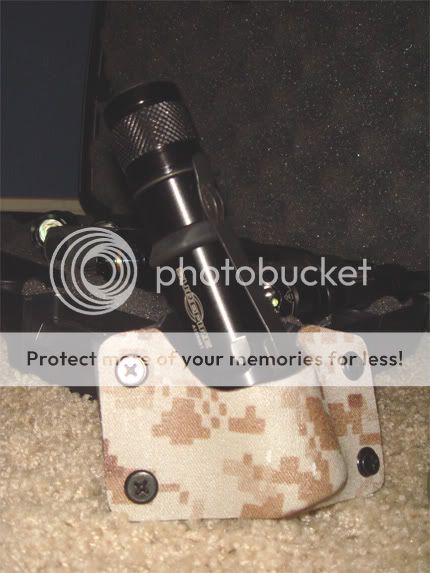

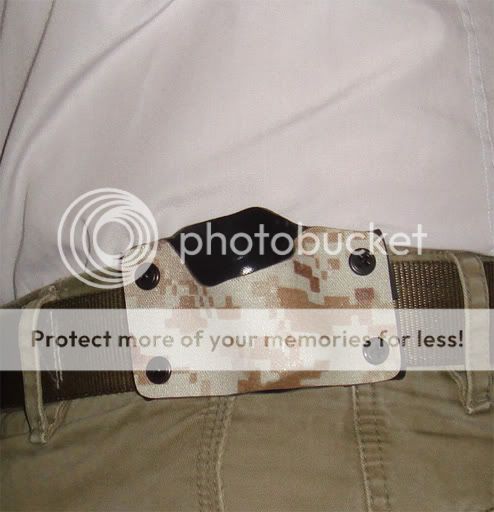

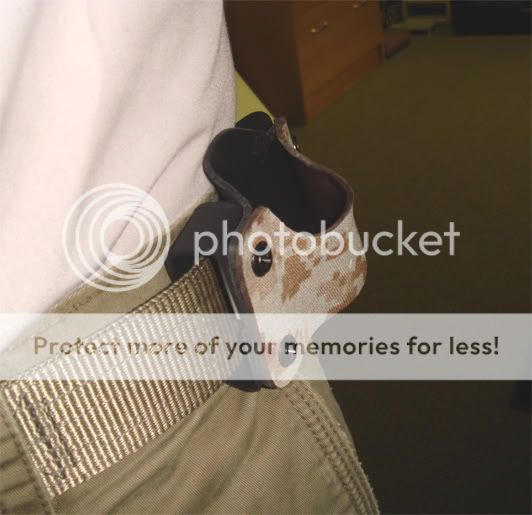

I have seen a few threads here lately discussing kydex flashlight holsters, and it gave me the motivation to try making my own. I didn't want to hijack any of the threads currently running, so I thought I'd start a new one to show my little project.

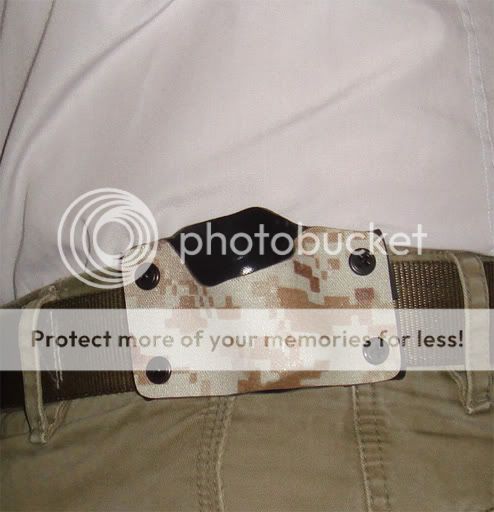

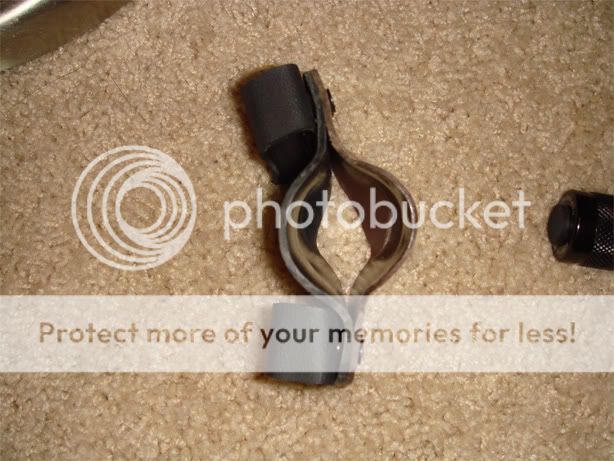

I have only made kydex holsters for handguns so far, so this was my first attempt at a light holster. I went about it the same way I do with my gun holsters, which is cutting, heating and pressing 2 pieces of kydex around the object, then cutting, sanding, and securing them together with rivets and screws. The entire project from start to finish took me about 2 hours, including making the belt loops.

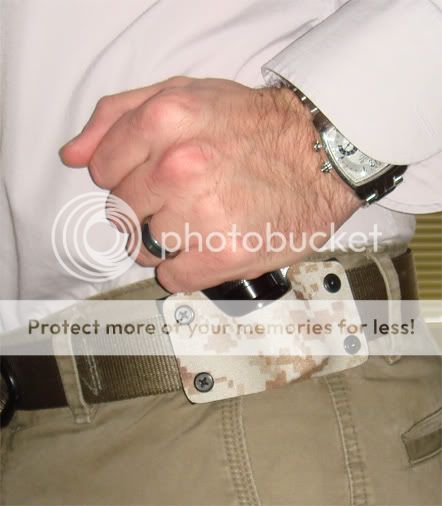

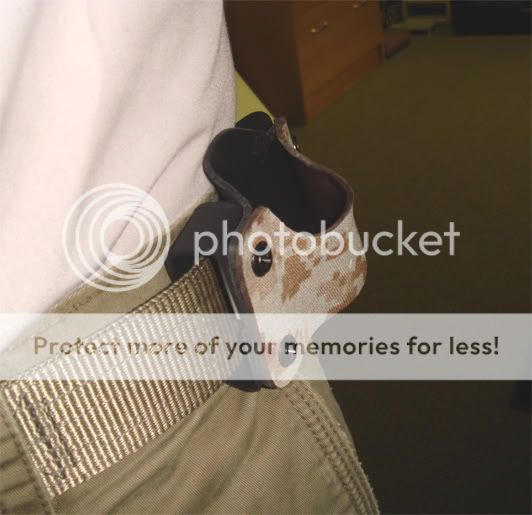

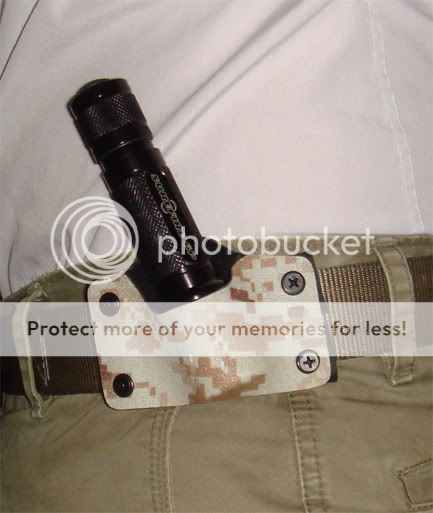

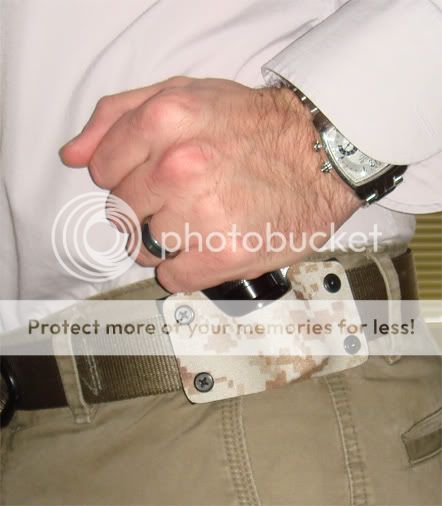

For a first attempt, I'm actually pretty satisfied. The retention on a standard Surefire P bezel is perfect. The light "clicks" securely into the holster, and you can turn it upside down and shake it as hard as possible, and the light stays put. When you want to quickly draw the light from the holster while on your belt, it pops out very easily with a light tug. I gave it a pretty aggressive forward cant, and it helps with the speed of both the draw and the re-holster.

It works perfectly with C and P bezels, holds a G bezel just fine (but without the satisfying "click" of retention) and even holds a G2X pretty well. Anyway, here are some pics:

I have only made kydex holsters for handguns so far, so this was my first attempt at a light holster. I went about it the same way I do with my gun holsters, which is cutting, heating and pressing 2 pieces of kydex around the object, then cutting, sanding, and securing them together with rivets and screws. The entire project from start to finish took me about 2 hours, including making the belt loops.

For a first attempt, I'm actually pretty satisfied. The retention on a standard Surefire P bezel is perfect. The light "clicks" securely into the holster, and you can turn it upside down and shake it as hard as possible, and the light stays put. When you want to quickly draw the light from the holster while on your belt, it pops out very easily with a light tug. I gave it a pretty aggressive forward cant, and it helps with the speed of both the draw and the re-holster.

It works perfectly with C and P bezels, holds a G bezel just fine (but without the satisfying "click" of retention) and even holds a G2X pretty well. Anyway, here are some pics: