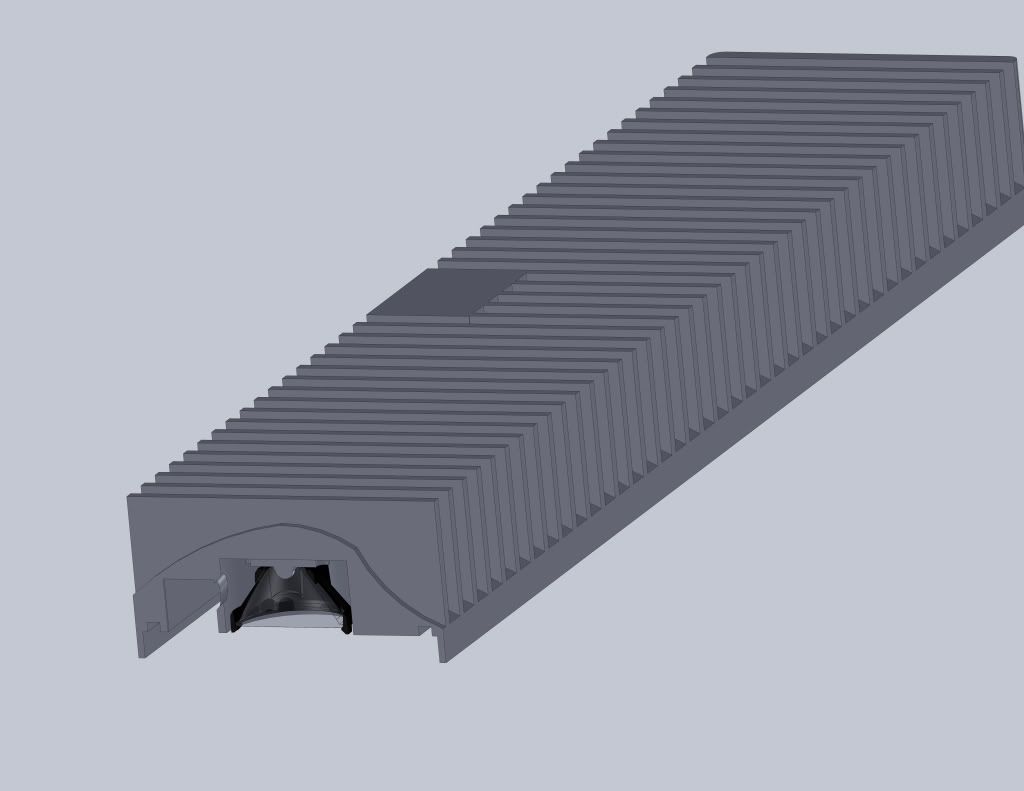

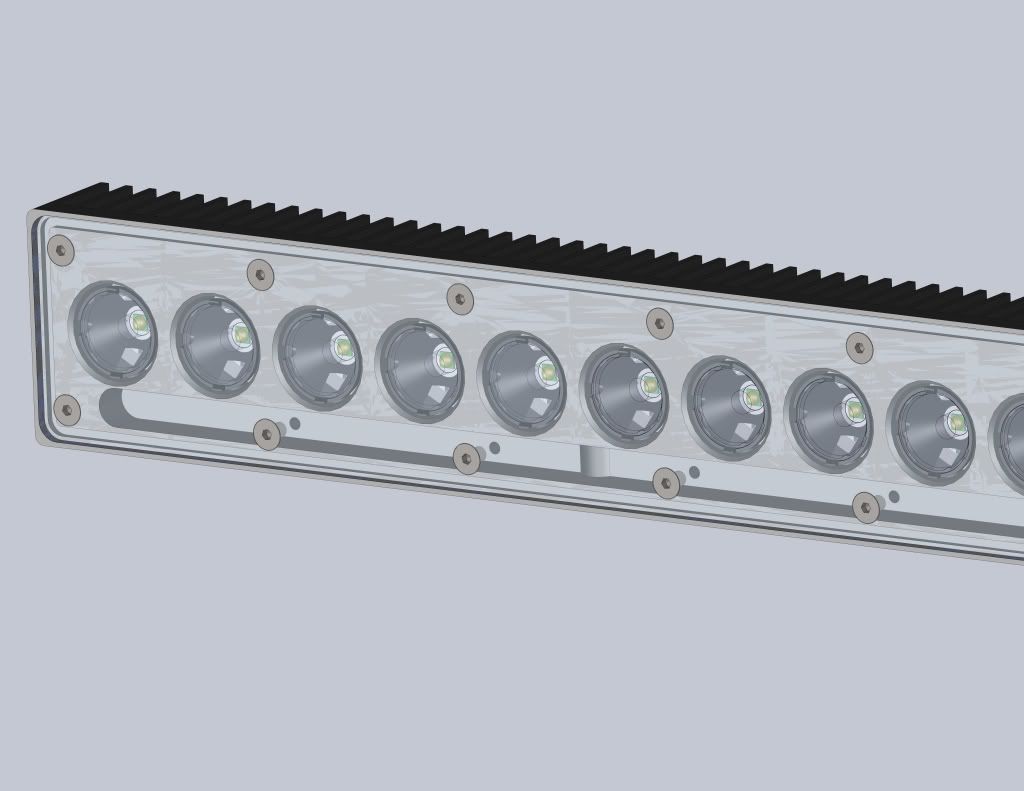

You guys think there is enough heatsinking? will be running at 2100mAH, about 8400lM.

what is the surfice area or the heatsink? how far apart are the fins?? someone said 10sqin per watt. don't know if it is thru but sounds reasonable. i never mesured or calculated heatsinks, i just guestimate, so far it worked, have good and bad experience, but if drawing is correct scale, i'd say it should work, looks big enough.

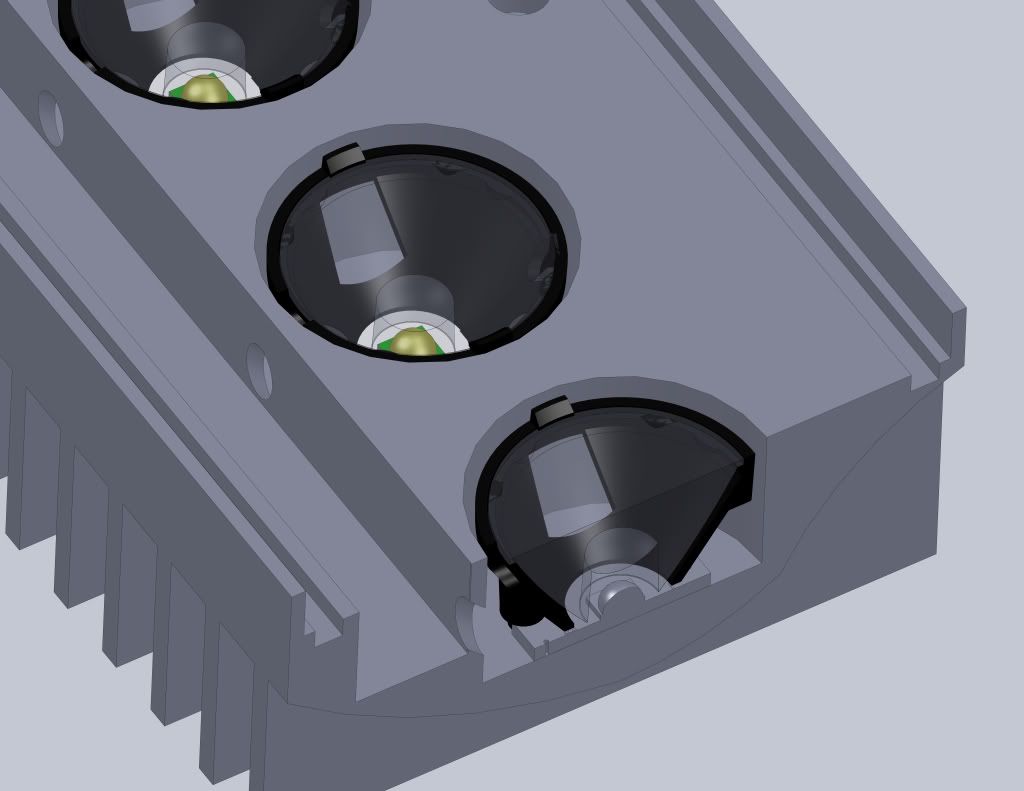

but that takes care of heat transfer after heat came from base of the star, the biggest bottleneck is the star itself, not all stars are made the same, 99% have thin layer of insulation between led's heatpad and the star itself, the led itself sits on layer of copper foil, some stars have thicker insulation, some thiner, (better heat transfer), some have large foil area, some small.

the best stars as of now is 16mm stars from ledtech.de they have heatpad sit directly on copper, with no insulation between, also xml stars from led supply, seem to have large foil area, can't say how thick insulation layer is, but i have not had any of them fail yet, so i'd say they are good too. but at 2100ma, they should work just fine.

also, if you,ll be using carclo 20 or 26,5mm lens for your flood light, use frosted, the lenses show a square around hotspot, and it is a bit off center, with clear lenses. carclo holder works great with 20mm star, it also works great with german 16mm star, after simple minimal filing.