I only signed up to steal knowledge from this forum, so forgive me for being parasitic. My questions relate to LEDs but they are for automotive purposes not torch purposes. Unfortunately there isn't really another forum around with so much knowledge about LEDs and light sources etc. I'd appreciate your wisdom guys!

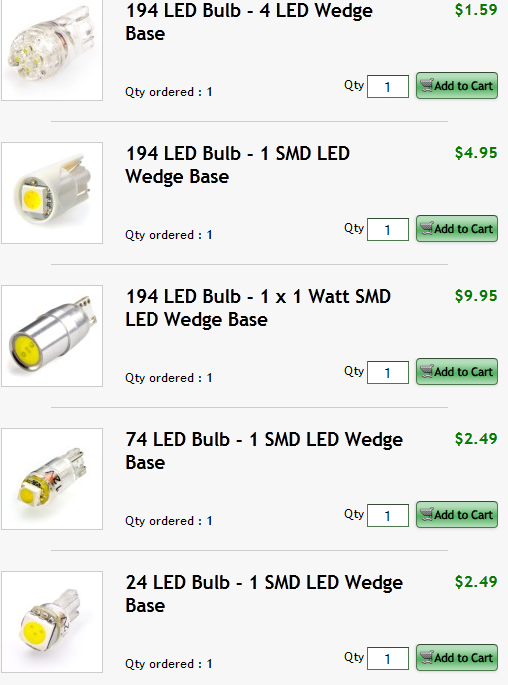

I am making some custom indicators (turn signal for the US folks) for my bike. They will be housed and hermetically sealed in a brass fitting similar to those used in plumping/fluid/air transfer. I have found this LED which looks very f* bright which I want http://www.superbrightleds.com/more...4-led-bulb-1-x-1-watt-smd-led-wedge-base/205/ . I

Q1. Will there be a problem with heat? It will be blinking at a normal indicator (turn signal) rate at the supplied 12v. There may be a very slim air pocket around the silver body. How much do these things heat up?

Q2. What is the best way to weatherproof/seal the LED face without compromising beam spread? I was thinking clear polyester resin, perspex disc drilled out with a hole saw, or premade glass lens of say 10mm diameter, but I haven't been able to find these anywhere <Q5?.

Q3. Is there a better purpose LED for this. It needs to be amber, wide angle, very f* bright, diameter of ~10mm or less, and doesn't require any circuitry to be complete ie just + - terminals soldiered.

I am making some custom indicators (turn signal for the US folks) for my bike. They will be housed and hermetically sealed in a brass fitting similar to those used in plumping/fluid/air transfer. I have found this LED which looks very f* bright which I want http://www.superbrightleds.com/more...4-led-bulb-1-x-1-watt-smd-led-wedge-base/205/ . I

Q1. Will there be a problem with heat? It will be blinking at a normal indicator (turn signal) rate at the supplied 12v. There may be a very slim air pocket around the silver body. How much do these things heat up?

Q2. What is the best way to weatherproof/seal the LED face without compromising beam spread? I was thinking clear polyester resin, perspex disc drilled out with a hole saw, or premade glass lens of say 10mm diameter, but I haven't been able to find these anywhere <Q5?.

Q3. Is there a better purpose LED for this. It needs to be amber, wide angle, very f* bright, diameter of ~10mm or less, and doesn't require any circuitry to be complete ie just + - terminals soldiered.

Last edited: