Asking here rather than Machining thread as I have limited tools.

I do have a decent quality mini drill press.

(I have a clamp kit so should be able to at least secure the reflector)

I have read of a few people successfully opening holes on reflectors.

Slow with a step piece I believe was done a few times.

Obvious question, how to manage the debri messing up reflector surface?

Run a vacuum cleaner underneath to suck the mess away?

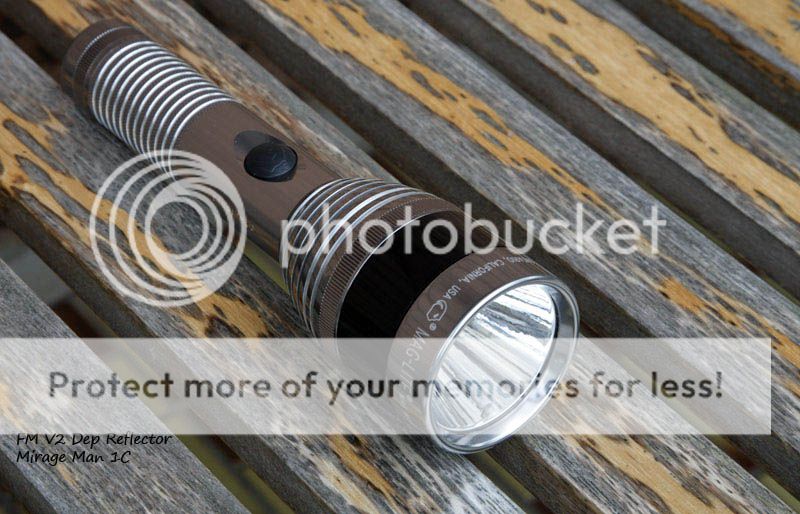

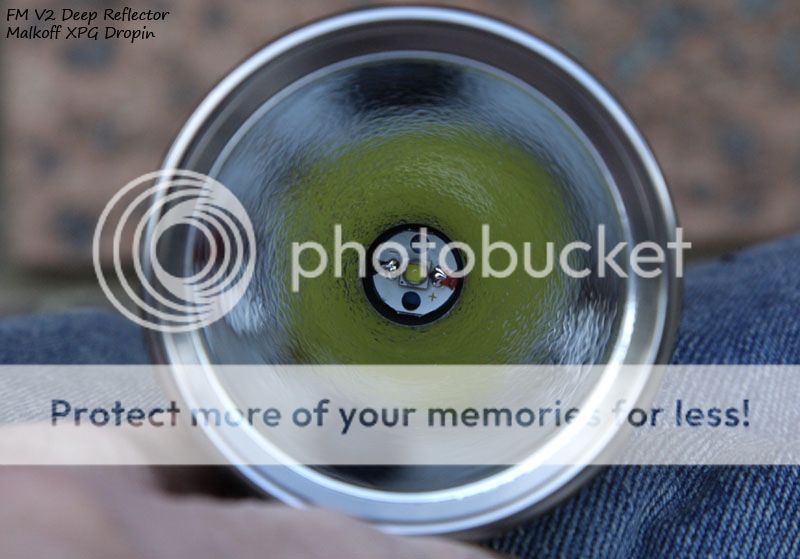

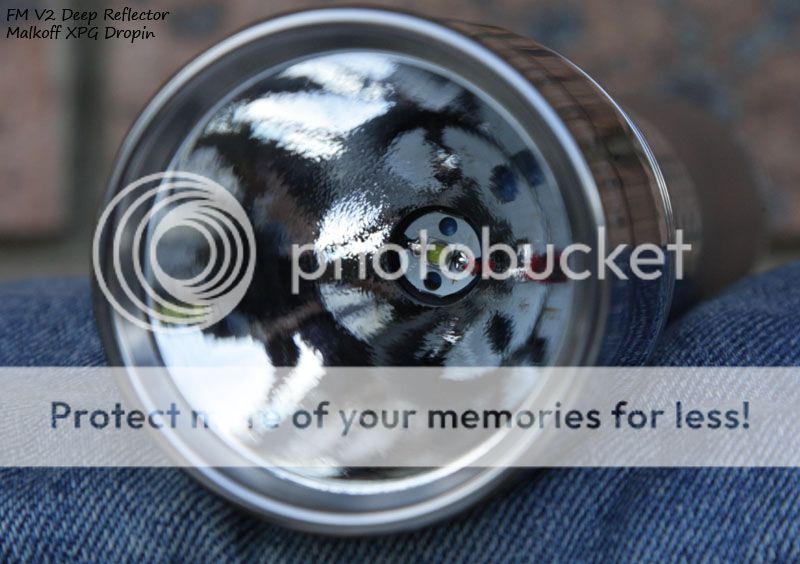

I have an FM 2 inch deep reflector, bought used, it's pretty old, has some very minor marks

so I'd use that as first try. Aim is to open 8.5mm hole to 12.5mm so it will fit around heatsink

pedestal on Malkoff mag drop ins. (XPG and XML)

If successful I'll risk a new 2 inch deep reflector I have.

I do have a decent quality mini drill press.

(I have a clamp kit so should be able to at least secure the reflector)

I have read of a few people successfully opening holes on reflectors.

Slow with a step piece I believe was done a few times.

Obvious question, how to manage the debri messing up reflector surface?

Run a vacuum cleaner underneath to suck the mess away?

I have an FM 2 inch deep reflector, bought used, it's pretty old, has some very minor marks

so I'd use that as first try. Aim is to open 8.5mm hole to 12.5mm so it will fit around heatsink

pedestal on Malkoff mag drop ins. (XPG and XML)

If successful I'll risk a new 2 inch deep reflector I have.