Mkala

Newly Enlightened

Hi All,

After finishing my 12V G4 LED replacement, here is my next project !

The goal is to light my garage. Here are the parameters, quite different of my last project, where quality of light was very important.

- Good efficacy, 80lm/w

- Neutral/Cool white is nice for a garage

- Easy to build

- Total size have to be small. Small hight is a key, too

- Wide angle, 120-150°

- Reasonable price

This time, I do not build a driver because I use a direct AC LED from Seoul Semiconductor !

The second generation of Acrich, called... Acrich2 ! Wow

This save me time to find/make a suitable driver. This save me space, too.

Efficacy is not the best of market, but a LED with 100lm/w with a driver with 80% efficiency result to 80lm/w same system efficacy, don't forget this.

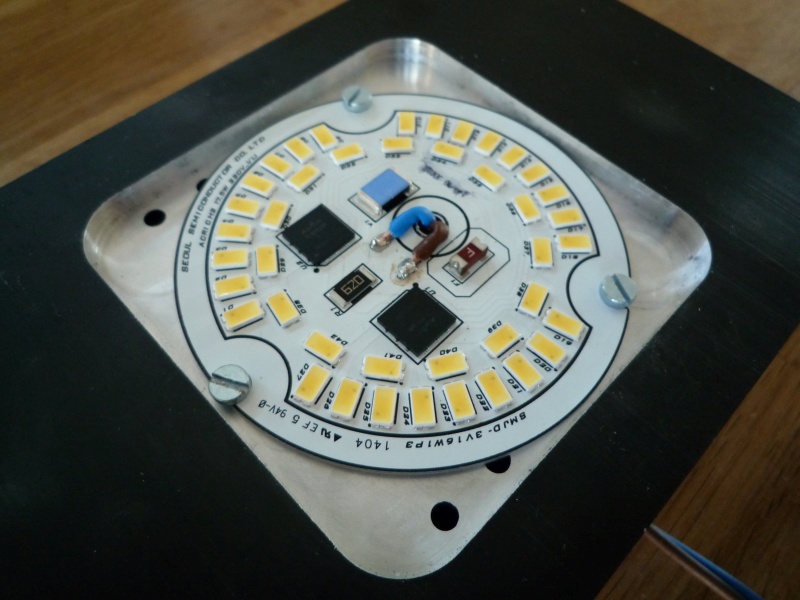

Here is a pic of my choice :

And its characteristics, model SMJD-3V16W1P3CA :

220V(230V) direct AC Drive

17.5W

1450lm (stated on Mouser site)

82 CRI (Mouser), min 80 CRI

5000k (original wish was 4000K, but now EoL)

<4.5mm height, 70mm diameter

More infos on the Acrich2 technology : http://www.candlepowerforums.com/vb...-LED-Driver-unusual-topology&highlight=acrich

Ok for the led light. The other "big" part, is cooling. As it is a garage, the design has not to be state of the art...

A "technical" style is good for me

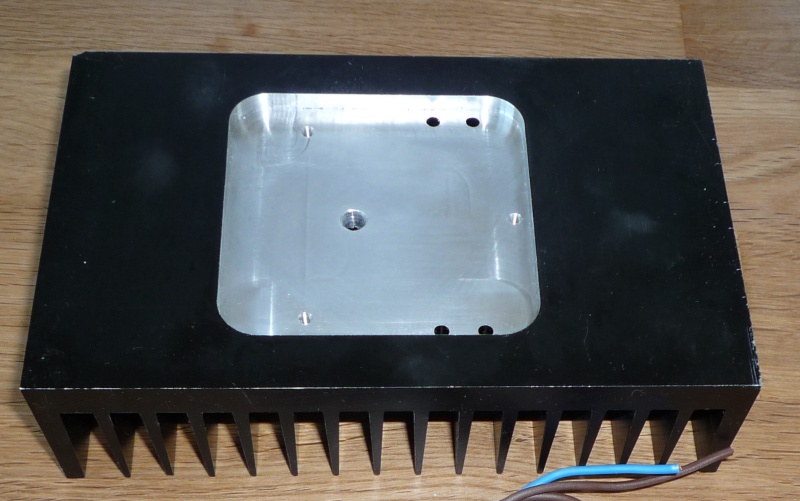

Chance, I have some heatsinks in stock : 0.9°C/W 160mm lang, 100mm wide, 40mm hight (SK 85/100/SA, Fischer Elektronik).

Money saved, they cost more than the LED...

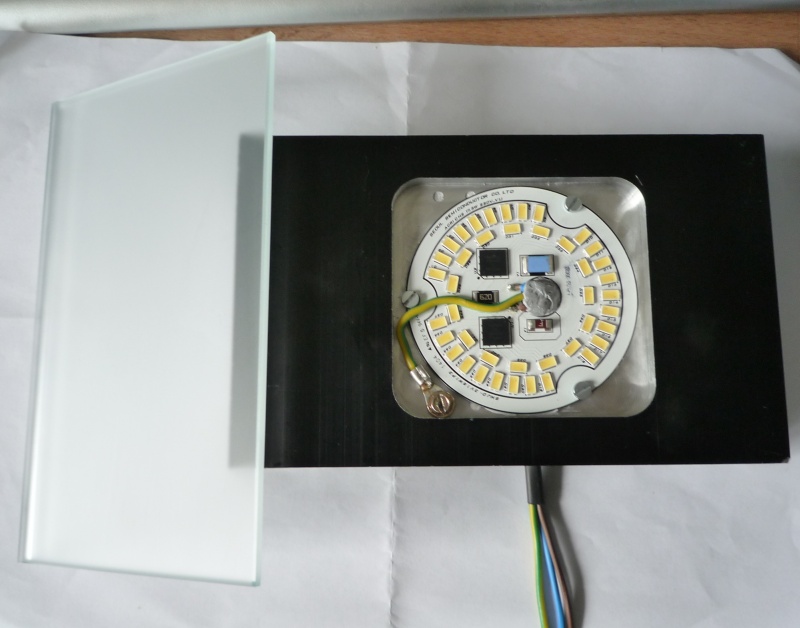

The design will be to machine the base side, to inlay the LED into it. The it will be covered with frosted tempered glass, glued/fixed with adhesive tape.

See you

After finishing my 12V G4 LED replacement, here is my next project !

The goal is to light my garage. Here are the parameters, quite different of my last project, where quality of light was very important.

- Good efficacy, 80lm/w

- Neutral/Cool white is nice for a garage

- Easy to build

- Total size have to be small. Small hight is a key, too

- Wide angle, 120-150°

- Reasonable price

This time, I do not build a driver because I use a direct AC LED from Seoul Semiconductor !

The second generation of Acrich, called... Acrich2 ! Wow

This save me time to find/make a suitable driver. This save me space, too.

Efficacy is not the best of market, but a LED with 100lm/w with a driver with 80% efficiency result to 80lm/w same system efficacy, don't forget this.

Here is a pic of my choice :

And its characteristics, model SMJD-3V16W1P3CA :

220V(230V) direct AC Drive

17.5W

1450lm (stated on Mouser site)

82 CRI (Mouser), min 80 CRI

5000k (original wish was 4000K, but now EoL)

<4.5mm height, 70mm diameter

More infos on the Acrich2 technology : http://www.candlepowerforums.com/vb...-LED-Driver-unusual-topology&highlight=acrich

Ok for the led light. The other "big" part, is cooling. As it is a garage, the design has not to be state of the art...

A "technical" style is good for me

Chance, I have some heatsinks in stock : 0.9°C/W 160mm lang, 100mm wide, 40mm hight (SK 85/100/SA, Fischer Elektronik).

Money saved, they cost more than the LED...

The design will be to machine the base side, to inlay the LED into it. The it will be covered with frosted tempered glass, glued/fixed with adhesive tape.

See you

Last edited: