Illum

Flashaholic

D26/P60 lamp modules have really came a long way, in fact every time theres something new I would upgrade and be left with several unused lamp assemblies. Here's what I need help with: I want to create an enclosure for them that's square for ease of mounting. Approximate dimensions of 1.5" x 1.5" x 1.5" [LxWxH]. The D26 LED modules will have the springs removed and prepped with a red positive wire. Somewhere on the block the negative wire will be crimped to a spade and screwed in place. If I can solder to the board I will prep the ground line right on the drop-in module.

To illustrate what I'm talking about here's a homemade contraption [that works really well] using a E2C adapter and a spare SOLARFORCE LC-XPL V3 dropin under an old 6P head. I bolted the E2C to a piece of scrap aluminum then tapped a 1/4-20 hole on it to mount it on a tripod stand. The negative wire is screwed on to the mounting piece. The module is snugged using copper foil tape then had the entire backside sealed using silicone rubber sealant after I soldered the wire to where the spring was. The module operated under water with no problems. I want something similar but square so both mounting chip cooler heatsinks and to a fixed location is easy.

As opposed to a screw on bezel, I will be able to fabricate 1-1/2" square lexan windows that can be bolted to the front then sealed in.

Just needs four holes on the front for the window, preferably tapped 4-40 as I have alot of machined screws in this thread. A window that'll look something like this.

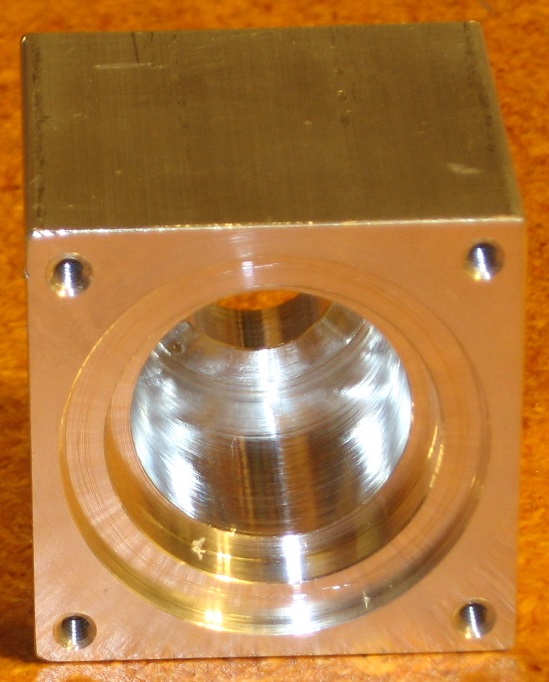

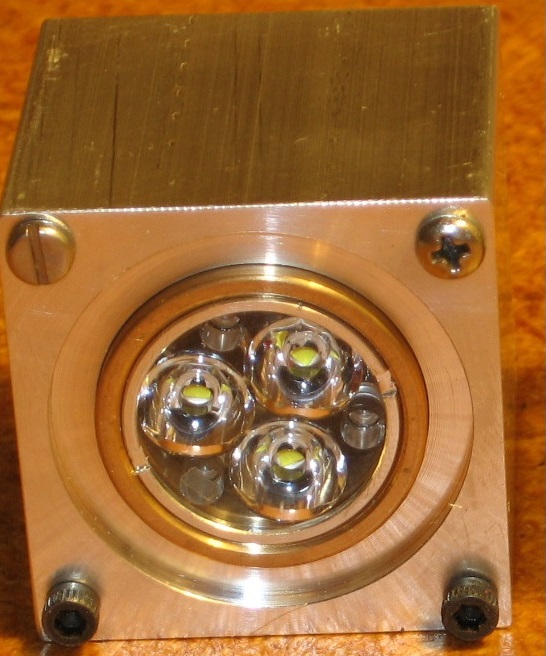

Without CAD on hand, I made a quick sketch of what a "twin" module would look like. The drawing was close to complete then got wet and smeared. The front of this aluminum block will have an approximately 1" opening that has a depth of approximately 3/16" before decreasing diameter to about 7/8". the 7/8" diameter will travel for 1" then exit with a 9/16" opening. There will be more than enough room to lay in two wires then backfill with sealant.

The front of this aluminum block will have an approximately 1" opening that has a depth of approximately 3/16" before decreasing diameter to about 7/8". the 7/8" diameter will travel for 1" then exit with a 9/16" opening. There will be more than enough room to lay in two wires then backfill with sealant.

The proposed dropins is the Eagletac Sportac single mode 3*XP-G2, which I will mail along for measurement with the metal stock and payment for service. I will need about 4 units made.

To illustrate what I'm talking about here's a homemade contraption [that works really well] using a E2C adapter and a spare SOLARFORCE LC-XPL V3 dropin under an old 6P head. I bolted the E2C to a piece of scrap aluminum then tapped a 1/4-20 hole on it to mount it on a tripod stand. The negative wire is screwed on to the mounting piece. The module is snugged using copper foil tape then had the entire backside sealed using silicone rubber sealant after I soldered the wire to where the spring was. The module operated under water with no problems. I want something similar but square so both mounting chip cooler heatsinks and to a fixed location is easy.

As opposed to a screw on bezel, I will be able to fabricate 1-1/2" square lexan windows that can be bolted to the front then sealed in.

Just needs four holes on the front for the window, preferably tapped 4-40 as I have alot of machined screws in this thread. A window that'll look something like this.

Without CAD on hand, I made a quick sketch of what a "twin" module would look like. The drawing was close to complete then got wet and smeared.

The front of this aluminum block will have an approximately 1" opening that has a depth of approximately 3/16" before decreasing diameter to about 7/8". the 7/8" diameter will travel for 1" then exit with a 9/16" opening. There will be more than enough room to lay in two wires then backfill with sealant.

The front of this aluminum block will have an approximately 1" opening that has a depth of approximately 3/16" before decreasing diameter to about 7/8". the 7/8" diameter will travel for 1" then exit with a 9/16" opening. There will be more than enough room to lay in two wires then backfill with sealant.

The proposed dropins is the Eagletac Sportac single mode 3*XP-G2, which I will mail along for measurement with the metal stock and payment for service. I will need about 4 units made.

Last edited: