Modernflame

Flashlight Enthusiast

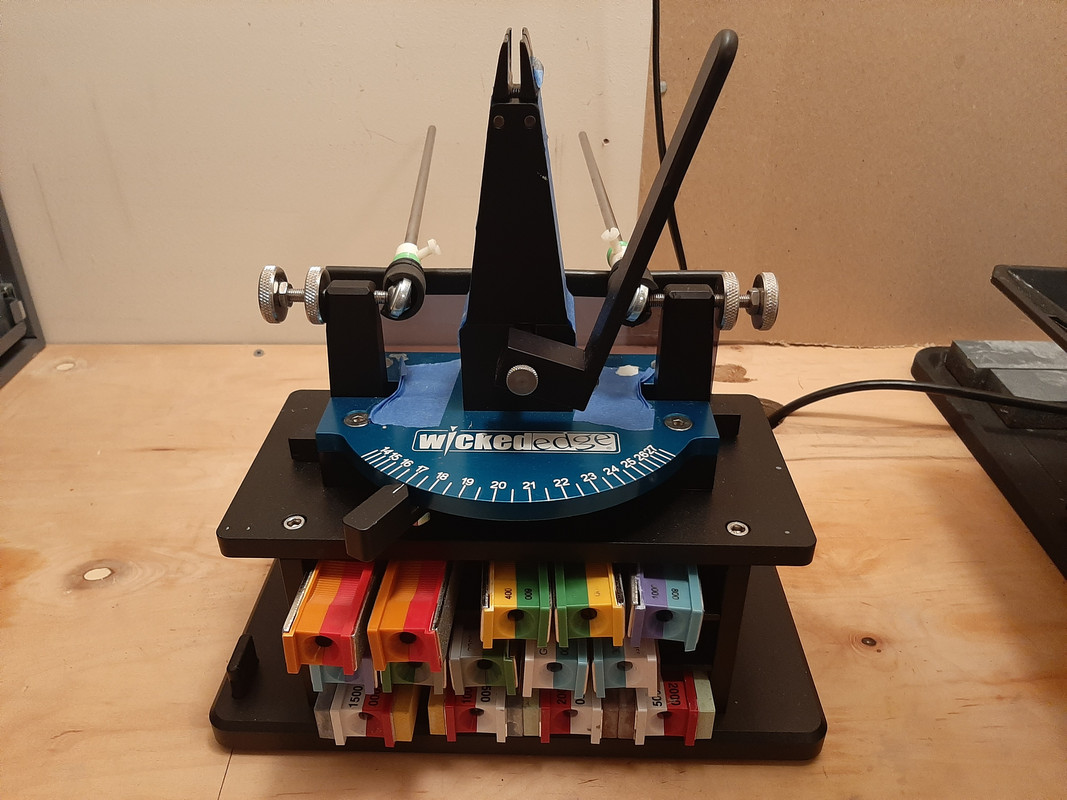

Versatile and precise, the Wicked Edge Gen 3 Pro enjoys widespread praise. However, this is not a discussion of its merits. Nor will this be a "how to sharpen" guide. Still less, a discussion on the virtues of fixed angle sharpening vs. freehand. Instead, I'd like to alert prospective buyers to the shortcomings of the system and to real world solutions.

We're talking about money, right? How much is precision sharpening worth? Each person must decide, but the Gen 3 Pro is currently listed at $899 on the WE website, although it can sometimes be had for $799. If you own a variety of knives or if you intend to operate commercially, you may be shocked to learn that you haven't finished spending money. Twelve shortcomings follow. The solutions mostly involve further purchases. In the end, there are still certain types of knives that cannot be serviced with the WE Gen 3 Pro.

Shortcomings:

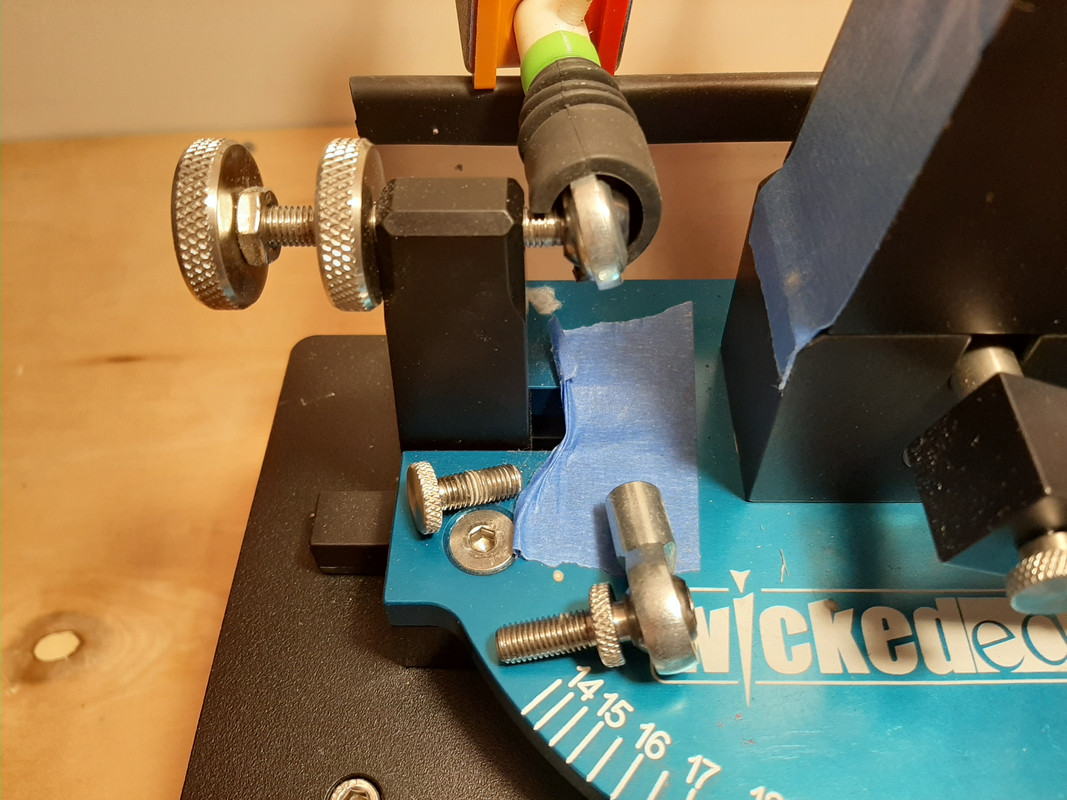

1) The stock hardware does not fix the angle. A glaring oversight, the locking nut does not prevent the angle from wandering as you work. The stock parts, displayed in front, screw left and right into the guide pylon. It works by dialing in the angle with the inner screw, then jamming the outer one against it. Even a few strokes with the stone can quickly dislodge the inner screw, changing the angle considerably. The owner of WE acknowledges the problem and is researching a remedy. Solution: A) Some have used teflon tape on the threads, but that does not inspire confidence for me. I tried wrapping the whole assembly in electrical tape, but that was not enough to stop the screw from turning. B) I have installed aftermarket parts at the cost of $110. A plastic version is available for about $40.

2) The Gen 3 pro does not include any strops in the basic kit. The diamond progression goes from 100 grit to 1000 grit, which leaves a refined if not polished finish. In fact, you could finish at 600 grit. Regardless, you will need some type of leather substrate with a micro abrasive to clean off your apex. I'd recommend including at least one set of strops, probably the four and two micron. Alternatively, you could make your own freehand strop for very little money, or buy a paddle strop online. Granted, other fixed angle systems do not provide strops in their basic kits, but those systems are typically much cheaper. Solution: Spend $66 more for at least one set of WE strops or find a cheaper freehand alternative.

3) The plastic finger guards prevent the stones from reaching the corner of a steep plunge grind on knives, like this Spyderco PM2. Solution: A) Live with it. You will have an unsharpened area of about ⅛" at the heel. This might not be feasible when sharpening someone else's knife, even if you accept this shortcoming for yourself. B) Cut the guards off, as I have done. If you do this, buy safety equipment. I use the A6 cut resistant gloves, available for $25. The plastic shields are an alternative at $10.

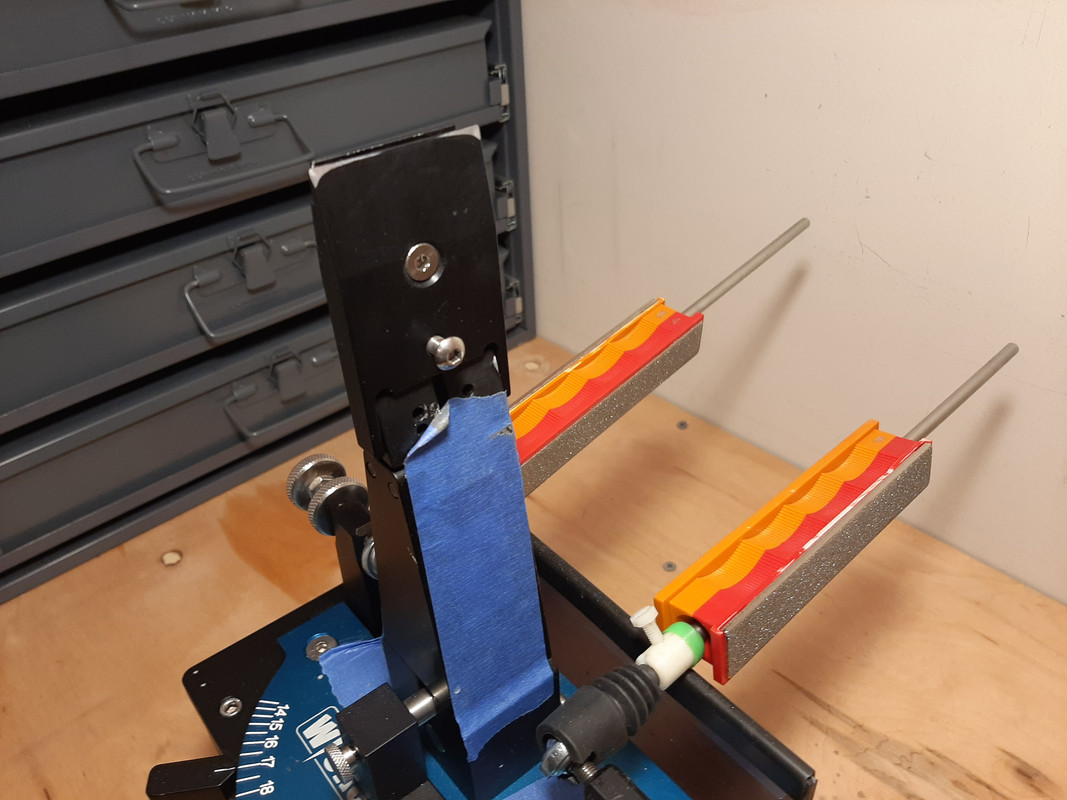

C) Buy aftermarket abrasives like these shapton pros, which stand well proud of the guards and therefore can reach into the corner. These cost roughly $100 per set. The drawback is that these aluminum oxide / ceramic abrasives are not suited to super steels with more than 3% vanadium.

4) The included 8" guide rods do not make sense for a benchtop model like the gen 3 pro. The 8" guide rods will service most pocket knives, outdoor knives and some kitchen knives, but they will not work for larger chef knives, especially ones that require an acute edge angle. (See the discussion of the low angle adapter below.) Many knives need to be clamped quite near the tip and canted at a forward angle to find the "sweet spot." This is the result of the circular movement of the guide rods.

On the straight portion of the blade, the WE will provide a consistent angle, regardless of the distance from the pivot. However, wherever the blade curves, it must be aligned with the curvature of the arc. If the knife is not canted forward, the WE will create a broader bevel at the belly than on the flat.

Thus, the 8" guide rods may not reach the heel. The low angle adapter (discussed below) will exacerbate the problem. Since this model does not aim for portability, why not include the 12" guide rods as standard equipment? Solution: Spend $30, $60, or $90 more on guide rods of differing lengths. I have 12" guide rods installed. Pictured here are the 8" alongside the 10" and 15" guide rods.

5) On narrow knives, the vise will not allow edge angles below 18 or 19 degrees. As you shallow out the angle, the stones strike the vice and are prevented from reaching the blade. Solution: Same as #6 below.

6) The vise will not allow for ultra low angle sharpening. Some high end kitchen knives have edge angles as low as 9 or 10 degrees. Solution: Spend another $75 on the low angle adapter. The increased height will allow a more acute angle, but you will need the 12" guide rods for chef knives. 10" chef knives may require the 15" guide rods.

7) The low angle adapter does not have the split clamp design. Blades with a distal taper will only be clamped in one small place. (Note how the standard clamp is split, allowing the vise to flex and hold the distal taper in two places.) This means that the low angle adapter has to be very tight to support the weight of the knife in the rear. However, if it is tight enough to support it, it is also tight enough to bend the blade in the front. Solution: See shortcoming #8 below.

8) Blade flex. Longer, thinner blades like filet knives or chef knives will flex under sharpening pressure, especially when clamped near the tip. The result will be a reduction in sharpness where the blade flexes and also an uneven bevel. Solution: My solution was to build this edifice.

It is unlovely to behold, but it is inexpensive and effective. This provides much needed vertical support in the rear, which means the low angle adapter can be relaxed so that it does not bend the front of the blade. It also eliminates blade flex as you sharpen toward the handle.

9) Blade thickness. The WE gen 3 vise is marvelously engineered and constructed. However, the standard clamp cannot accommodate blades with a spine thickness greater than 3/16". This is plenty for most knives, but be aware that many outdoor knives are ¼" or more. Solution: Spend $75 on the ¼" jaws, but some knives are even thicker and cannot be sharpened using the WE gen 3 vise. The older model of WE vise may be preferable if this is a concern.

10) Small knives. Many traditional folding knives, pen knives, and Swiss Army knives have blades that are too small to be clamped. If the knife is clamped securely, then the edge will not protrude with sufficient clearance to meet the abrasive at any reasonable angle.

Solution: Spend $35 on the Tormek Small Knife Adapter. There is another limitation, even with this accessory. Folding knives with multiple slots, like Swiss Army Knives, may not have the blade in the center slot. If a small knife is well off center in the handle, you won't be able to use the WE, regardless of what accessory you use.

11) Convex grinds. The radius of a convex grind is difficult to replicate with any fixed angle system. Solution: A) Convex grinds can be created on the WE, but involves a taxing process of sharpening at several different angles. This would be a faceted edge, rather than a true convex. B) Invest in a different sharpening system, like the KME, which offers a convex sharpening rod that applies a 5 degree radius to the edge.

12) Recurves. This is another problem common to fixed angle systems that use 1" wide abrasives. Solution: A) WE sells a two grit curved ceramic abrasive for $120. Remember that ceramics may not be ideal for super steels with a high vanadium content. B) Buy a KME. They make a three grit diamond abrasive platen with a narrow, curved surface.

Finally, two suggestions. First, I recommend the purchase of an angle cube with an accuracy rating of 0.05 degrees. These are more expensive and more difficult to find than the common cubes with an accuracy rating of 0.20 degrees. I bought this for something like $65. Second, if you're invested this far, splurge and buy a wide selection of grits. If you do these two things, you will get the most out of your WE.

Types of knives that cannot be serviced with the Wicked Edge Gen 3 Pro:

We're talking about money, right? How much is precision sharpening worth? Each person must decide, but the Gen 3 Pro is currently listed at $899 on the WE website, although it can sometimes be had for $799. If you own a variety of knives or if you intend to operate commercially, you may be shocked to learn that you haven't finished spending money. Twelve shortcomings follow. The solutions mostly involve further purchases. In the end, there are still certain types of knives that cannot be serviced with the WE Gen 3 Pro.

Shortcomings:

1) The stock hardware does not fix the angle. A glaring oversight, the locking nut does not prevent the angle from wandering as you work. The stock parts, displayed in front, screw left and right into the guide pylon. It works by dialing in the angle with the inner screw, then jamming the outer one against it. Even a few strokes with the stone can quickly dislodge the inner screw, changing the angle considerably. The owner of WE acknowledges the problem and is researching a remedy. Solution: A) Some have used teflon tape on the threads, but that does not inspire confidence for me. I tried wrapping the whole assembly in electrical tape, but that was not enough to stop the screw from turning. B) I have installed aftermarket parts at the cost of $110. A plastic version is available for about $40.

2) The Gen 3 pro does not include any strops in the basic kit. The diamond progression goes from 100 grit to 1000 grit, which leaves a refined if not polished finish. In fact, you could finish at 600 grit. Regardless, you will need some type of leather substrate with a micro abrasive to clean off your apex. I'd recommend including at least one set of strops, probably the four and two micron. Alternatively, you could make your own freehand strop for very little money, or buy a paddle strop online. Granted, other fixed angle systems do not provide strops in their basic kits, but those systems are typically much cheaper. Solution: Spend $66 more for at least one set of WE strops or find a cheaper freehand alternative.

3) The plastic finger guards prevent the stones from reaching the corner of a steep plunge grind on knives, like this Spyderco PM2. Solution: A) Live with it. You will have an unsharpened area of about ⅛" at the heel. This might not be feasible when sharpening someone else's knife, even if you accept this shortcoming for yourself. B) Cut the guards off, as I have done. If you do this, buy safety equipment. I use the A6 cut resistant gloves, available for $25. The plastic shields are an alternative at $10.

C) Buy aftermarket abrasives like these shapton pros, which stand well proud of the guards and therefore can reach into the corner. These cost roughly $100 per set. The drawback is that these aluminum oxide / ceramic abrasives are not suited to super steels with more than 3% vanadium.

4) The included 8" guide rods do not make sense for a benchtop model like the gen 3 pro. The 8" guide rods will service most pocket knives, outdoor knives and some kitchen knives, but they will not work for larger chef knives, especially ones that require an acute edge angle. (See the discussion of the low angle adapter below.) Many knives need to be clamped quite near the tip and canted at a forward angle to find the "sweet spot." This is the result of the circular movement of the guide rods.

On the straight portion of the blade, the WE will provide a consistent angle, regardless of the distance from the pivot. However, wherever the blade curves, it must be aligned with the curvature of the arc. If the knife is not canted forward, the WE will create a broader bevel at the belly than on the flat.

Thus, the 8" guide rods may not reach the heel. The low angle adapter (discussed below) will exacerbate the problem. Since this model does not aim for portability, why not include the 12" guide rods as standard equipment? Solution: Spend $30, $60, or $90 more on guide rods of differing lengths. I have 12" guide rods installed. Pictured here are the 8" alongside the 10" and 15" guide rods.

5) On narrow knives, the vise will not allow edge angles below 18 or 19 degrees. As you shallow out the angle, the stones strike the vice and are prevented from reaching the blade. Solution: Same as #6 below.

6) The vise will not allow for ultra low angle sharpening. Some high end kitchen knives have edge angles as low as 9 or 10 degrees. Solution: Spend another $75 on the low angle adapter. The increased height will allow a more acute angle, but you will need the 12" guide rods for chef knives. 10" chef knives may require the 15" guide rods.

7) The low angle adapter does not have the split clamp design. Blades with a distal taper will only be clamped in one small place. (Note how the standard clamp is split, allowing the vise to flex and hold the distal taper in two places.) This means that the low angle adapter has to be very tight to support the weight of the knife in the rear. However, if it is tight enough to support it, it is also tight enough to bend the blade in the front. Solution: See shortcoming #8 below.

8) Blade flex. Longer, thinner blades like filet knives or chef knives will flex under sharpening pressure, especially when clamped near the tip. The result will be a reduction in sharpness where the blade flexes and also an uneven bevel. Solution: My solution was to build this edifice.

It is unlovely to behold, but it is inexpensive and effective. This provides much needed vertical support in the rear, which means the low angle adapter can be relaxed so that it does not bend the front of the blade. It also eliminates blade flex as you sharpen toward the handle.

9) Blade thickness. The WE gen 3 vise is marvelously engineered and constructed. However, the standard clamp cannot accommodate blades with a spine thickness greater than 3/16". This is plenty for most knives, but be aware that many outdoor knives are ¼" or more. Solution: Spend $75 on the ¼" jaws, but some knives are even thicker and cannot be sharpened using the WE gen 3 vise. The older model of WE vise may be preferable if this is a concern.

10) Small knives. Many traditional folding knives, pen knives, and Swiss Army knives have blades that are too small to be clamped. If the knife is clamped securely, then the edge will not protrude with sufficient clearance to meet the abrasive at any reasonable angle.

Solution: Spend $35 on the Tormek Small Knife Adapter. There is another limitation, even with this accessory. Folding knives with multiple slots, like Swiss Army Knives, may not have the blade in the center slot. If a small knife is well off center in the handle, you won't be able to use the WE, regardless of what accessory you use.

11) Convex grinds. The radius of a convex grind is difficult to replicate with any fixed angle system. Solution: A) Convex grinds can be created on the WE, but involves a taxing process of sharpening at several different angles. This would be a faceted edge, rather than a true convex. B) Invest in a different sharpening system, like the KME, which offers a convex sharpening rod that applies a 5 degree radius to the edge.

12) Recurves. This is another problem common to fixed angle systems that use 1" wide abrasives. Solution: A) WE sells a two grit curved ceramic abrasive for $120. Remember that ceramics may not be ideal for super steels with a high vanadium content. B) Buy a KME. They make a three grit diamond abrasive platen with a narrow, curved surface.

Finally, two suggestions. First, I recommend the purchase of an angle cube with an accuracy rating of 0.05 degrees. These are more expensive and more difficult to find than the common cubes with an accuracy rating of 0.20 degrees. I bought this for something like $65. Second, if you're invested this far, splurge and buy a wide selection of grits. If you do these two things, you will get the most out of your WE.

Types of knives that cannot be serviced with the Wicked Edge Gen 3 Pro:

- Serrated knives, like bread knives.

- Some Swiss Army knives and traditional folders.

- Knives with a spine thickness greater than ¼"

- Recurves or hawkbills. WE only offers two grits with a curved surface. May not be suitable for steep curves.

- Asymmetrical grinds, like 70/30 Japanse kitchen knives would present a significant challenge, because the Gen 3 Pro is inherently symmetrical.

Last edited: