PEU

Flashlight Enthusiast

This thread is derived from This one

I'm starting this new thread because it will show the real progress, from paper to product, and when it's finished it will be officially named.

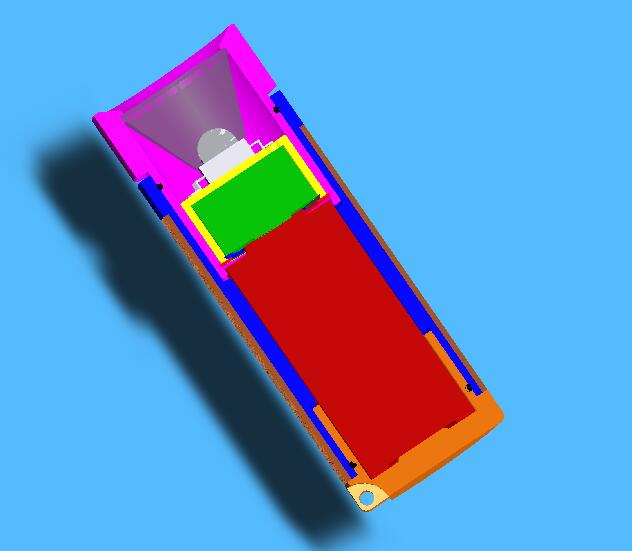

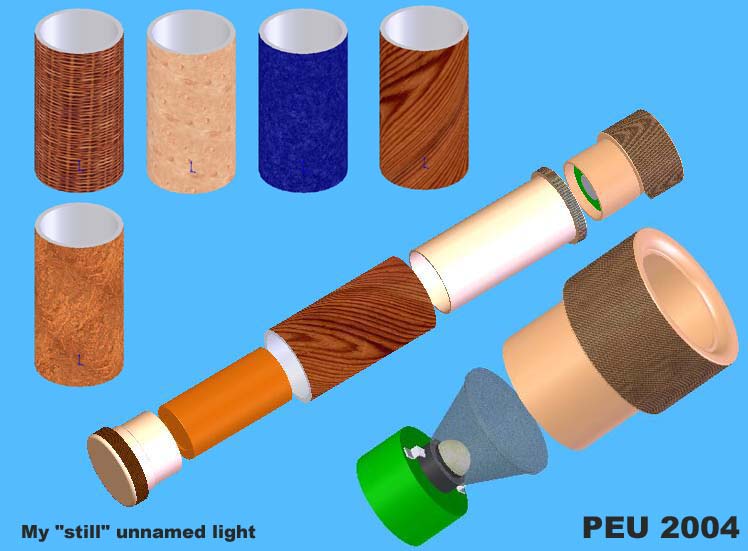

Here is the exploded view as designed in SW:

The skins from left to right: basket mesh, maple, plastic blue, tea pine, cork.

Hope you like it.

EDIT 1/19/2005

Interest list:

#1 Modamag ($43)

#2 Frenchyled ($43)

#3 Amorphous ($43) (withdrew from the list)

#3 PeterB ($43+$15)

#4 Gadgetometry ($43+15)

#5 Gadgetometry ($43+15)

#6 Marcspar ($43)

#7 JonSidneyB ($Paid)

#8 PeterB ($43+15)

#9

#10 <-reach this and its a GO

#11

#12

#13

#14

#15

#16

#17

#18

#19

#20

EDIT 2/7/2005

PAYPAL PROBLEM UPDATE / PLEASE READ

Pablo

I'm starting this new thread because it will show the real progress, from paper to product, and when it's finished it will be officially named.

Here is the exploded view as designed in SW:

The skins from left to right: basket mesh, maple, plastic blue, tea pine, cork.

Hope you like it.

EDIT 1/19/2005

Interest list:

#1 Modamag ($43)

#2 Frenchyled ($43)

#3 Amorphous ($43) (withdrew from the list)

#3 PeterB ($43+$15)

#4 Gadgetometry ($43+15)

#5 Gadgetometry ($43+15)

#6 Marcspar ($43)

#7 JonSidneyB ($Paid)

#8 PeterB ($43+15)

#9

#10 <-reach this and its a GO

#11

#12

#13

#14

#15

#16

#17

#18

#19

#20

EDIT 2/7/2005

PAYPAL PROBLEM UPDATE / PLEASE READ

Pablo