Johnbeck180

Enlightened

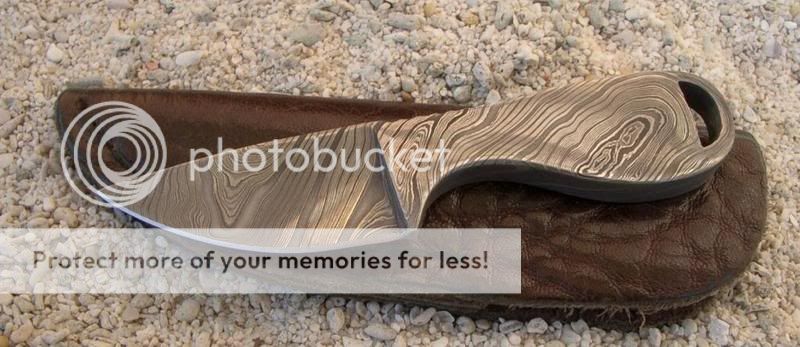

Your mokume is great. I am a cofessed flashaholic, but I am also a knife maker. I make damascus knifes out of two or three different kinds of carbon steel and knives made out of high carbon steel. You should check out bladeforums. Some of the bladesmiths might like you stuff.

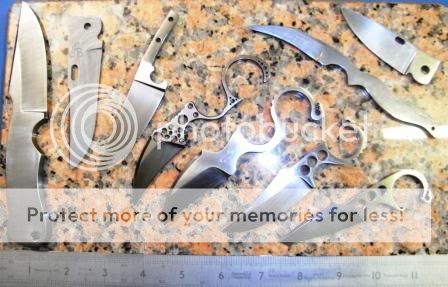

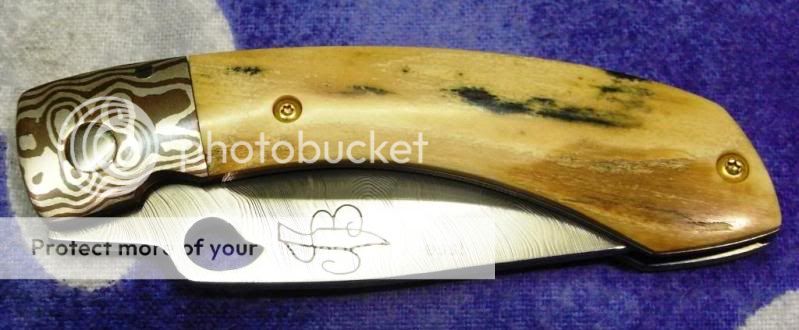

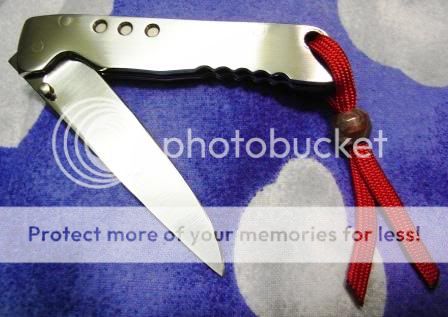

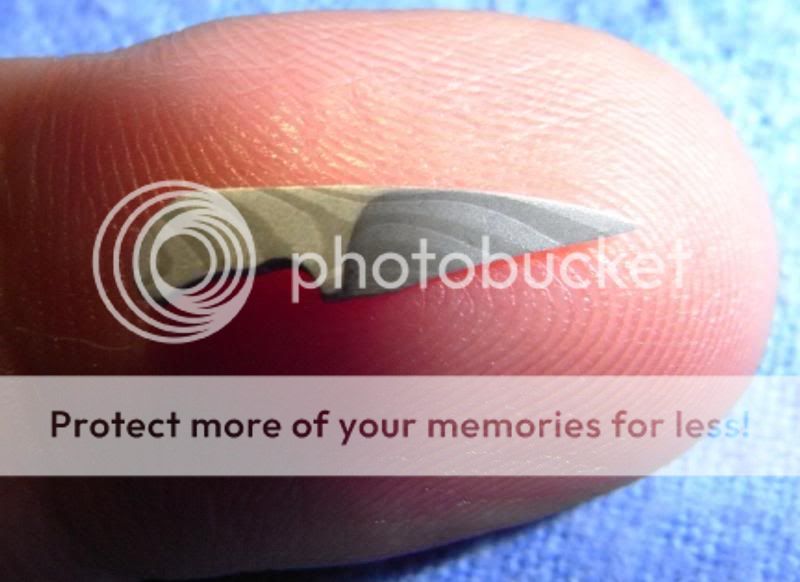

Here is a pic of two of my knives. The one on the left is damascus witch is taking different steels and forge welding them together, like mokume. The orange Handled one is just hi carbon steel I think it's 5160 steel.

Here is a pic of two of my knives. The one on the left is damascus witch is taking different steels and forge welding them together, like mokume. The orange Handled one is just hi carbon steel I think it's 5160 steel.

Last edited: