j333_76484

Newly Enlightened

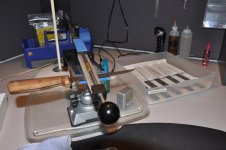

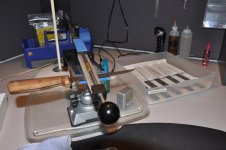

Finally get to sit down and sharpen some of my own knives as opposed to doing everyone else's knives. Will be taking the bevel on this fillet knife down from 18 degrees to 15 then taking the edge all the way up to a 32K grit stone then swap over to using Nano cloth and Kangaroo hide with CBN Sprays. Should end up with a highly polished edge once done. Not needed at all. Just enjoy doing it.

Last edited: