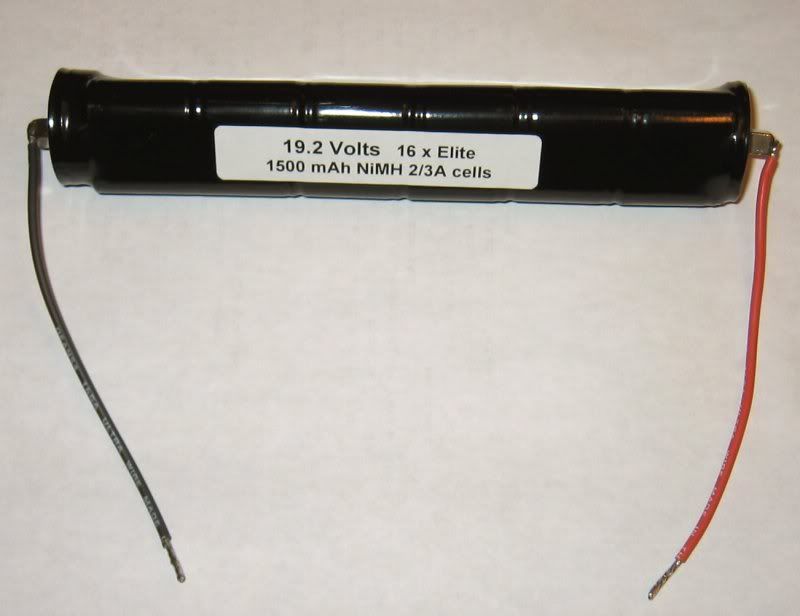

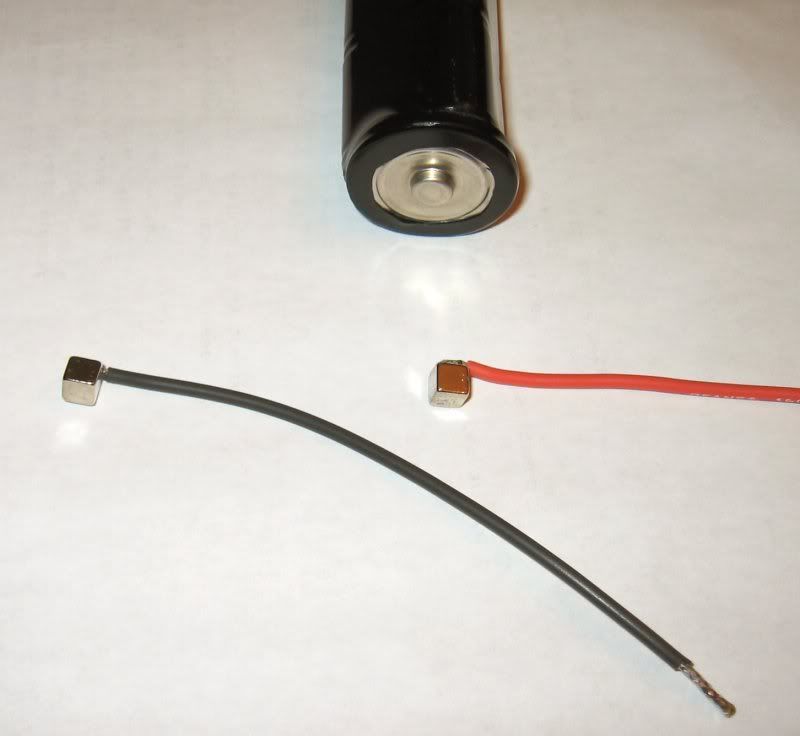

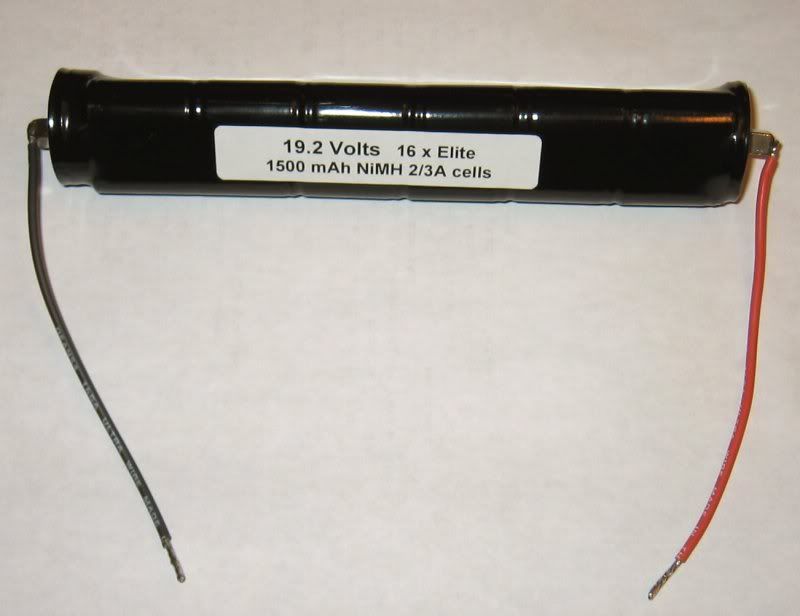

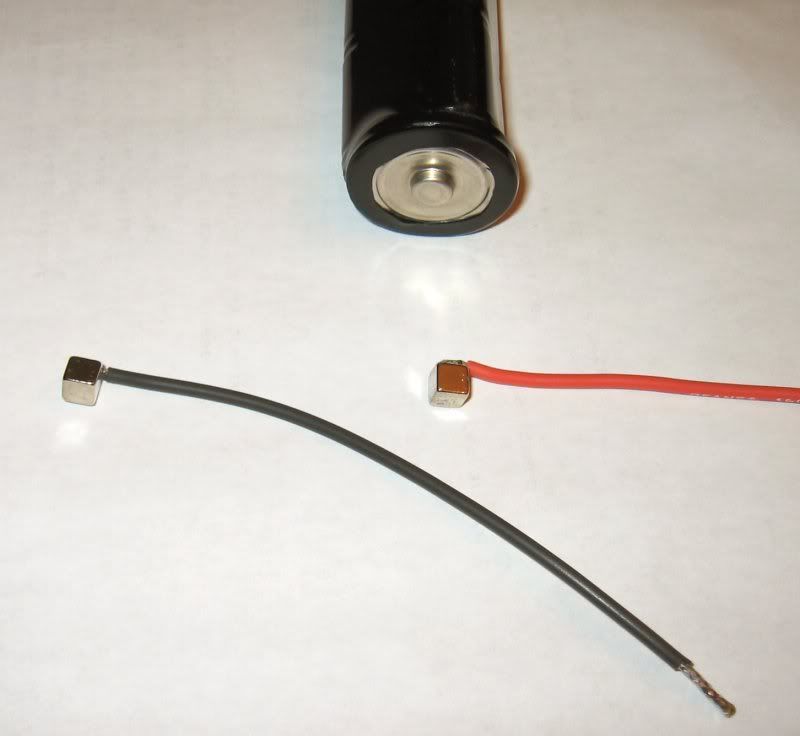

OK, I'm in a groove with this baby. Snap Snap, Shrink Shrink, Sweet Sweet. Doing some packs for people now, and throwing in these magnet (1/4" cube K&J N-50 stronger magnets) leads that I am making.....have to get your technique down to avoid demagnetizing from the soldering.

Next up.....Li-Ion setups with tap leads.

Next up.....Li-Ion setups with tap leads.