You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SkyRC — IFA 2014 — MC3000 charger-analyzer

- Thread starter kreisl

- Start date

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

I agree. The lost of charging settings is a completely nonsense. That's why I don't want to upgrade for negligible improvements, otherwise I would try to upgrade. Moreover I find incredible they did not implemented a way to backup / restore of all charging settings.

- Joined

- Mar 7, 2007

- Messages

- 650

There is an extensive thread on this on BLF - with the same dismay expressed over the lack of a firmware update changelog. As Geppo says, its crazy that you have to lose your programs IF you do a firmware update.I agree. The lost of charging settings is a completely nonsense. That's why I don't want to upgrade for negligible improvements, otherwise I would try to upgrade. Moreover I find incredible they did not implemented a way to backup / restore of all charging settings.

GREAT charger, still the best, most flexible, out there by far, but updating etc leave much to be desired.

dmenezes

Newly Enlightened

Does anyone know what's new in firmware release 1.18?

Here's a copy/paste from my post on BLF:

Following up on this, early this morning I managed to get ahold of a helpful representative at the SkyRC website chat, and asked about v1.17 (which came on my SkyRC MC3000, purchased late last April), the previous version v1.15, and the current one v1.18;

- Initial discussion about firmware versions for the MC3000, specially v1.15 vs v1.18 (will be continued here): Checking mAh - #58 by dmenezes (and the next 4 posts following it).

TL;DR: v1.17 has a bug (related to the operation of D.REDUCE setting and possibly to its "inverse similar during CV-Phase of Li-Ion battery charging"[1] which is why SkyRC does not make that version available for download, and instead recommend updating to v1.18. I asked about falling back to 1.15 in case 1.18 doesn't work for me, but they apparently evaded that question.

[1] see the SkyRC manual p.22, under "D.REDUCE".

And here's the complete transcript (edited for clarity/brevity):

I hope this is helpful to other MC3000 owners.13 Sep, 2023

[15:08] DMenezes: I have an SkyRC MC3000 with firmware 1.17. I see there's an update available for firmware 1.18, but I'm worried that the new firmware could not work as well and I would need to go back to the old one.

[15:09] DMenezes: I searched the SkyRC website for version 1.17 so I could go back to it if needed, but could but could not find it. I could find version 1.15, tho.

[15:11] DMenezes: My question is, is there a reason the older version (1.15) is available for download, but the newer one (1.17) isn't?

[17:34] SkyRC: There is a bug in V1.17

[17:34] SkyRC: So we did not put it on the site

[17:35] SkyRC: The bug is about the charge or discharge reduce

[17:50] DMenezes: Ok, so I better upgrade ASAP, I guess

[18:34] DMenezes: if I upgrade to 1.18 and it doesn't work for me, should I then move to 1.15?

[18:45] SkyRC: I believe 1.18 will work for you

dmenezes

Newly Enlightened

Thanks much for the link(s) and your comments. Now I at least have one entry for my list of possible sources, and that sure beats zero

If you haven't purchased yours yet, here's where I bought mine from ealier this year: https://www.progressiverc.com/products/skyrc-mc3000-multi-chemistry-charger

Product had good price (cheaper than on Amazon), was shipped promptly, and arrived in perfect condition. Chadd, the technical lead there, was very helpful and answered all my questions over emails, and was very accommodating re: my unusual shipping requirements. To sum it up, I couldn't be happier about them.

dmenezes

Newly Enlightened

I've been seeing some VERY weird behavior re: IR measurements on my SkyRC MC3000.

Here's a copy/paste from my original post on BLF, reposting here as it seems CPF has more MC3000 users:

--------------------

SkyRC MC3000, weird IR measurement behavior with firmware 1.18

As per above. In my continuing usage and tests, I've seen two types of strange behavior:

One thing that could explain what I've seen is that I first started the discharge on the MJ1 batteries (on slots #2 and #3) and only about 3 mins afterwards (as it has different parameters) I did the same on battery #1. Perhaps when I statrted the discharge on #1, it messed up the IR measurement for the other two?

Anyway that behavior makes no sense and seems like a bug. Would like to know if anyone else here ever saw anything similar.

TIA!

--------------------

So, that weird behavior seems to be related to the slot: #1 keeps its initial value while #2 and #3 lose theirs, no matter the order their operations get started.

--------------------

Much obliged to anyone here on CPF (or wherever) that can help me understand that.

TIA!

Here's a copy/paste from my original post on BLF, reposting here as it seems CPF has more MC3000 users:

--------------------

SkyRC MC3000, weird IR measurement behavior with firmware 1.18

As per above. In my continuing usage and tests, I've seen two types of strange behavior:

- Sometimes internal resistance (IR) gets measured (and can be seen on the charger display and the Android app), and sometimes not (ie, it shows as "N/A") ; this led me to start manually commanding an IR measurement every time right after inserting the batteries and before starting whatever operation (charge, discharge,refresh, etc)I was about to do with them, by pressing both arrow keys simultaneously on the panel. Which right now lead me to #2 below.

- Even after manually commanding an IR measurement and having it displayed for all 3 batteries in the charger, right now it happened that, after starting the operation I was interested for (in this case, a discharge of all 3 batteries down to 2.5V in order to measure their remaining capacity), 2 of these batteries (in slots #2 and #3) changed their IR measurement to "N/A" (the remaining battery, the one in slot #1, kept showing its initial IR measurement).

One thing that could explain what I've seen is that I first started the discharge on the MJ1 batteries (on slots #2 and #3) and only about 3 mins afterwards (as it has different parameters) I did the same on battery #1. Perhaps when I statrted the discharge on #1, it messed up the IR measurement for the other two?

Anyway that behavior makes no sense and seems like a bug. Would like to know if anyone else here ever saw anything similar.

TIA!

--------------------

More data: just repeated the above with the exact same batteries and in the same slots, but now with a charge operation and first starting the battery in slot #1 and then the batteries in slots #2 and #3, but despite changing the order, the exact same behavior repeated: slots #2 and #3 changed their IR measurements from the values that were initially measured to "N/A", while slot #1 kept showing it.One thing that could explain what I've seen is that I first started the discharge on the MJ1 batteries (on slots #2 and #3) and only about 3 mins afterwards (as it has different parameters) I did the same on battery #1. Perhaps when I statrted the discharge on #1, it messed up the IR measurement for the other two?

So, that weird behavior seems to be related to the slot: #1 keeps its initial value while #2 and #3 lose theirs, no matter the order their operations get started.

--------------------

Much obliged to anyone here on CPF (or wherever) that can help me understand that.

TIA!

Lowglow

Newly Enlightened

I've owned 3 of these excellent chargers and they get daily use. Sadly the first one (first batch made available) has bit the dust. Slot 3 gave unstable (high) voltage reading that fluctuated around as I looked at it. I was going to just use the other slots but then the plastic spring retaining peg snapped off on slot 2. It's already had one new top panel so that was it.

Sadly my second (backup) unit snapped two spring posts yesterday. And upon opening it the other two are just holding on. It seems to me like this fault will be very common.

So I have started a repair. I'm not sure if anyone has tried similar but I'm wanting to make it 'better than new'. I drilled a 2mm hole in the middle of the reinforced area at the bottom of the snapped peg - not too far or it will come through into the battery holder - then screwed in a M2.5 x 10mm grub screw with some JB Weld around the bottom into the hole. Then checked that the screws match up with the holes in the PCB. This is rock solid so you have not only the PCB holding the screw but the plastic and JB weld too.

It takes time and care but it is solid!

Sadly my second (backup) unit snapped two spring posts yesterday. And upon opening it the other two are just holding on. It seems to me like this fault will be very common.

So I have started a repair. I'm not sure if anyone has tried similar but I'm wanting to make it 'better than new'. I drilled a 2mm hole in the middle of the reinforced area at the bottom of the snapped peg - not too far or it will come through into the battery holder - then screwed in a M2.5 x 10mm grub screw with some JB Weld around the bottom into the hole. Then checked that the screws match up with the holes in the PCB. This is rock solid so you have not only the PCB holding the screw but the plastic and JB weld too.

It takes time and care but it is solid!

- Joined

- Mar 7, 2007

- Messages

- 650

Sounds like good work!I've owned 3 of these excellent chargers and they get daily use. Sadly the first one (first batch made available) has bit the dust. Slot 3 gave unstable (high) voltage reading that fluctuated around as I looked at it. I was going to just use the other slots but then the plastic spring retaining peg snapped off on slot 2. It's already had one new top panel so that was it.

Sadly my second (backup) unit snapped two spring posts yesterday. And upon opening it the other two are just holding on. It seems to me like this fault will be very common.

So I have started a repair. I'm not sure if anyone has tried similar but I'm wanting to make it 'better than new'. I drilled a 2mm hole in the middle of the reinforced area at the bottom of the snapped peg - not too far or it will come through into the battery holder - then screwed in a M2.5 x 10mm grub screw with some JB Weld around the bottom into the hole. Then checked that the screws match up with the holes in the PCB. This is rock solid so you have not only the PCB holding the screw but the plastic and JB weld too.

It takes time and care but it is solid!

Is your second (backup) unit also from the first batch? The second batch (June 2016 Production) was supposed to have all those retaining peg problems solved.

Lowglow

Newly Enlightened

Lowglow

Newly Enlightened

As far as I know the second one was revised. For the first batch they offer the revised part as a spare which I ordered but that broke and my later one broke also. However more improvements may have been made along the way.Sounds like good work!

Is your second (backup) unit also from the first batch? The second batch (June 2016 Production) was supposed to have all those retaining peg problems solved.

Lowglow

Newly Enlightened

Ok I've overcome another issue. One of the 6 plastic pegs that the casing screws drive into was snapped right off. It had initially cracked in two then those two bits were rattling inside the case. But I was able to fix it. If you look at the broken off pegs there is a portion left at the base that can save the day. I used a screw from the 'Halfords self tapping screw selection' box that under scrutiny had identical thread pitch and diameter but was around 1/4" longer. You need no more than 1/8" longer with the point ground off.

You have so little left the point will come through the case if you are not careful.

Now it's secure and I thought I'd share as other users must be having similar problems.

I love the charger but the case material is dissapointing.

You have so little left the point will come through the case if you are not careful.

Now it's secure and I thought I'd share as other users must be having similar problems.

I love the charger but the case material is dissapointing.

- Joined

- Mar 7, 2007

- Messages

- 650

They were supposed to have fixed ALL the problems including the case material in the third production which came with the two fans.Ok I've overcome another issue. One of the 6 plastic pegs that the casing screws drive into was snapped right off. It had initially cracked in two then those two bits were rattling inside the case. But I was able to fix it. If you look at the broken off pegs there is a portion left at the base that can save the day. I used a screw from the 'Halfords self tapping screw selection' box that under scrutiny had identical thread pitch and diameter but was around 1/4" longer. You need no more than 1/8" longer with the point ground off.

You have so little left the point will come through the case if you are not careful.

Now it's secure and I thought I'd share as other users must be having similar problems.

I love the charger but the case material is dissapointing.

Lowglow

Newly Enlightened

That's good news as I got someone to buy one for themselves recently. My ones must be second run then as just one fan.They were supposed to have fixed ALL the problems including the case material in the third production which came with the two fans.

So pleased that they fixed the issues later on but must be loads put there with problems with the plastic. They used to offer the top panel for $15 but no longer it seems.

- Joined

- Mar 7, 2007

- Messages

- 650

I assumed that they no longer offered replacement tops because they figured they fixed all the plastic problems in the 'two fans' (third) version.They used to offer the top panel for $15 but no longer it seems.

I also seem to recall that there is a discussion of the plastic issues somewhere several years back in this very long thread.

Lowglow

Newly Enlightened

Yes it's got so long that it's hard to find stuff now. If the materials have improved and are now reliable that's good. But that leaves a lot of older examples with difficult to fix problems. Expensive bit of kit to just bin.I assumed that they no longer offered replacement tops because they figured they fixed all the plastic problems in the 'two fans' (third) version.

I also seem to recall that there is a discussion of the plastic issues somewhere several years back in this very long thread.

@Lowglow

Thanx for your posts regarding the repairs and remediation measures you've taken w/ your MC3000(s). Having only recently acquired one, I'm still making friends with it, but it's looking like it will be a good friendship. Good on ya for keeping them functional, despite the challenges imposed by the use of the trashy materials in their case construction (at least in earlier generations) EDIT: and its design.

I expect I'll be depending on this gadget as 'critical equipment' for some time. Although I've not been using it long, I already realize that I wouldn't want to be without it. Because nothing else has come on the market which can truly and effectively replace it yet (to the best of my knowledge), together with my lacking high confidence in its continued availability long term(?), I'm considering getting a backup. Given that replacement housings are apparently no longer available, I'm thinking you might want to consider doing likewise and acquiring a(nother), latest version 'backup' for your older unit(s) for perhaps the same reasons. I'm certainly not trying to spend your money, but when I started thinking of ordering a second one, I thought of you. 'Just sayin'' ;-)

Anyway, thanx for the cool info!

Thanx for your posts regarding the repairs and remediation measures you've taken w/ your MC3000(s). Having only recently acquired one, I'm still making friends with it, but it's looking like it will be a good friendship. Good on ya for keeping them functional, despite the challenges imposed by the use of the trashy materials in their case construction (at least in earlier generations) EDIT: and its design.

I expect I'll be depending on this gadget as 'critical equipment' for some time. Although I've not been using it long, I already realize that I wouldn't want to be without it. Because nothing else has come on the market which can truly and effectively replace it yet (to the best of my knowledge), together with my lacking high confidence in its continued availability long term(?), I'm considering getting a backup. Given that replacement housings are apparently no longer available, I'm thinking you might want to consider doing likewise and acquiring a(nother), latest version 'backup' for your older unit(s) for perhaps the same reasons. I'm certainly not trying to spend your money, but when I started thinking of ordering a second one, I thought of you. 'Just sayin'' ;-)

Anyway, thanx for the cool info!

Last edited:

Lowglow

Newly Enlightened

Thanks for the reply.@Lowglow

Thanx for your posts regarding the repairs and remediation measures you've taken w/ your MC3000(s). Having only recently acquired one, I'm still making friends with it, but it's looking like it will be a good friendship. Good on ya for keeping them functional, despite the challenges imposed by the use of the trashy materials in their case construction (at least in earlier generations) EDIT: and its design.

I expect I'll be depending on this gadget as 'critical equipment' for some time. Although I've not been using it long, I already realize that I wouldn't want to be without it. Because nothing else has come on the market which can truly and effectively replace it yet (to the best of my knowledge), together with my lacking high confidence in its continued availability long term(?), I'm considering getting a backup. Given that replacement housings are apparently no longer available, I'm thinking you might want to consider doing likewise and acquiring a(nother), latest version 'backup' for your older unit(s) for perhaps the same reasons. I'm certainly not trying to spend your money, but when I started thinking of ordering a second one, I thought of you. 'Just sayin'' ;-)

Anyway, thanx for the cool info!

Yes it really is an important bit of kit. I used to spoil rechargeable NiMh in my old charger- and that was a reccomeded model too. They never terminated and just got blazing hot. Not the MC3000 though, I can see exactly what's going on and after some calibration with my Fluke multimeter the batteries are balanced so nicely. I have never seen a missed termination yet.

Good call - I may well do that. I did sometimes use all three simultaneously like when charging a light that takes 11 AA batteries so I'll definitely be looking out for one.

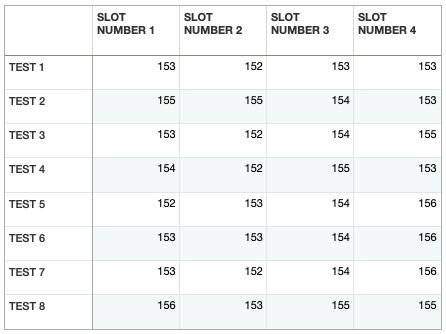

MC3000 Internal Resistance Measurement Consistency Check

After recently acquiring an MC3000, I did a very simple, small-scale test to get a sense of its IR test measurement consistency / repeatability under real-world conditions, when used as intended / directed by a typical user, while observing best practices and introducing no other variables. I'm posting the numbers in case any readers might for various reasons find them interesting or useful.

My unit is box-stock, and has not had a screw turned. It self-identifies as being FW Version 1.15 and HW Version 2.2. It was purchased directly from an established U.S. distributor.

For my test I used a single brand new 16340 ('protected') cell which had only 2 discharge cycles on it to verify its health, was then charged to 4.2V and had then sat for several weeks, which allowed it to settle and reach a stable resting voltage. I chose the 16340 as the smallest cells I use, and to minimize cell terminal contact spring pressure, which if anything would be 'worst case' for the test / contact resistance.

I inserted the cell into Slot 1, waited for a stable display reflecting that, pressed the 'UP+DN' keys to initiate an IR test, and recorded the result. I then removed the cell, and waited for the display to reflect the empty slot status.

I then re-inserted the cell into Slot 1 and repeated the above process 3 more times (for a total of 4 measurements), then repeated that entire process for each of Slots 2-4 (for a total of 16 measurements). Those numbers are listed as Tests 1-4 in the chart. When I shut the unit down and sat down to actually look at the numbers, I decided I needed more data points. I then got the unit back out and repeated the entire procedure above, thus providing me with 32 measurements distributed across all 4 slots. That second set of numbers is listed as Test Numbers 5-8 in the chart.

Looking at the numbers for a couple of minutes, I realized there was no need to grab my trusty old HP11; the numbers completely spoke for themselves and answered the question which prompted me to do the little test to my satisfaction.

I note little pattern, aside from perhaps a seeing a slight trend as I look diagonally down the chart towards the area of lower right corner, possibly seeing 1 or 2 of the 'higher' numbers (by 1 or 2 counts) perhaps appearing more in that area. Those are the last measurements taken on the second pass. If so, that possible slight trend would likely be accounted for by the fact that the MC3000 uses a couple of discharge pulses to do the DCIR test, and while not a big thing, the little cell did see rather a lot of them during the testing, and they do add up. I believe that as SOC decreases, DCIR increases, which could have shifted the average measurements higher by a fraction of a 'count' / milliohm or so. I'm talking about mouse attachments here though. In practical terms, these numbers don't require much analysis on their surface. Note that possible factors behind the numbers is another matter entirely though.

I may have some additional comments regarding these numbers and what's behind them later, but for now will just let them 'speak for themselves'. Any comments or questions about what I did are welcome, and if anyone has representative data from any other unit / device which would correlate / be comparable with this data (gathered using the same real-world methodology apples-to-apples), that would also be welcomed. "What's in your wallet?"

After recently acquiring an MC3000, I did a very simple, small-scale test to get a sense of its IR test measurement consistency / repeatability under real-world conditions, when used as intended / directed by a typical user, while observing best practices and introducing no other variables. I'm posting the numbers in case any readers might for various reasons find them interesting or useful.

My unit is box-stock, and has not had a screw turned. It self-identifies as being FW Version 1.15 and HW Version 2.2. It was purchased directly from an established U.S. distributor.

For my test I used a single brand new 16340 ('protected') cell which had only 2 discharge cycles on it to verify its health, was then charged to 4.2V and had then sat for several weeks, which allowed it to settle and reach a stable resting voltage. I chose the 16340 as the smallest cells I use, and to minimize cell terminal contact spring pressure, which if anything would be 'worst case' for the test / contact resistance.

I inserted the cell into Slot 1, waited for a stable display reflecting that, pressed the 'UP+DN' keys to initiate an IR test, and recorded the result. I then removed the cell, and waited for the display to reflect the empty slot status.

I then re-inserted the cell into Slot 1 and repeated the above process 3 more times (for a total of 4 measurements), then repeated that entire process for each of Slots 2-4 (for a total of 16 measurements). Those numbers are listed as Tests 1-4 in the chart. When I shut the unit down and sat down to actually look at the numbers, I decided I needed more data points. I then got the unit back out and repeated the entire procedure above, thus providing me with 32 measurements distributed across all 4 slots. That second set of numbers is listed as Test Numbers 5-8 in the chart.

Looking at the numbers for a couple of minutes, I realized there was no need to grab my trusty old HP11; the numbers completely spoke for themselves and answered the question which prompted me to do the little test to my satisfaction.

I note little pattern, aside from perhaps a seeing a slight trend as I look diagonally down the chart towards the area of lower right corner, possibly seeing 1 or 2 of the 'higher' numbers (by 1 or 2 counts) perhaps appearing more in that area. Those are the last measurements taken on the second pass. If so, that possible slight trend would likely be accounted for by the fact that the MC3000 uses a couple of discharge pulses to do the DCIR test, and while not a big thing, the little cell did see rather a lot of them during the testing, and they do add up. I believe that as SOC decreases, DCIR increases, which could have shifted the average measurements higher by a fraction of a 'count' / milliohm or so. I'm talking about mouse attachments here though. In practical terms, these numbers don't require much analysis on their surface. Note that possible factors behind the numbers is another matter entirely though.

I may have some additional comments regarding these numbers and what's behind them later, but for now will just let them 'speak for themselves'. Any comments or questions about what I did are welcome, and if anyone has representative data from any other unit / device which would correlate / be comparable with this data (gathered using the same real-world methodology apples-to-apples), that would also be welcomed. "What's in your wallet?"

Last edited:

I'm surprised that the values aren't more spread out. Of course, this may have something to do with the fact that the internal resistance of this small battery is already quite high. This means that different contact resistances are less important. The deviations will be larger if the internal resistance is lower.

I suggest you do the same test again with one cell from your collection that has the lowest internal resistance.

Then you do a second series of tests with this cell and proceed as I do with an internal resistance measurement in order to keep the contact resistance as small as possible.

You place the cell in the charging slot, press the negative contact with the inserted battery slightly towards the positive contact with one hand and turn the cell back and forth a little.

Then you press harder against the negative contact and maintain the pressure while you trigger the measurement.

I suggest you do the same test again with one cell from your collection that has the lowest internal resistance.

Then you do a second series of tests with this cell and proceed as I do with an internal resistance measurement in order to keep the contact resistance as small as possible.

You place the cell in the charging slot, press the negative contact with the inserted battery slightly towards the positive contact with one hand and turn the cell back and forth a little.

Then you press harder against the negative contact and maintain the pressure while you trigger the measurement.

Thanks for that feedback! That's exactly the primary reason why I did this test, and is exactly what I wanted such feedback on. I knew many would be 'surprised', because many have stated that such consistency is impossible to achieve in a charger/analyzer of this general design. In my judgement / opinion, my results so far establish that is not the case.I'm surprised that the values aren't more spread out.

Note that possible factors behind the numbers is another matter entirely though.

I may have some additional comments regarding these numbers and what's behind them later, but for now will just let them 'speak for themselves'.

the numbers completely spoke for themselves and answered the question which prompted me to do the little test to my satisfaction.

There's an old lawyer saying that 'when cross-examining a witness, never ask a question you do not already know the answer to'. I believe I already know the reason behind the apparent consistency of these numbers. If I'm correct, the answer lies in the design of the unit, not the way I did this test. Before getting into that, I'd like more feedback first, specifically subjective opinions (such as the first line of your post) on the nature of these test results from the very specific test I did, exactly as I did it. It seems you're already trying to address the reason(s) behind why the numbers look as they do. I will get to that, as I stated, but not at this moment; you're getting ahead of me. My simple test was designed / done after very careful and thorough consideration of all the relevent technical factors / considerations involved, and was precisely designed to best provide the specific information I needed to answer the specific question I had, with as few variables as possible, which I feel it has already done perfectly.

if anyone has representative data from any other unit / device which would correlate / be comparable with this data (gathered using the same real-world methodology apples-to-apples), that would also be welcomed. "What's in your wallet?"

If you have a 4-slot charger/analyzer (whatever brand / type you use) and would like to help further, results of any test you might find time to do would be useful and appreciated. Use whatever type of cell you wish, although do keep in mind that the shorter the cell, the lower the cell terminal spring pressure, and therefore is the best way to expose any inherent variability in distributed measurement circuit resistance, which is generally believed to be the primary cause of measurement inconsistency, which is what this test is all about. A longer cell would only mask the deficiencies of the unit in this regard, and that's was not my objective; quite the contrary. I'm not trying to get the lowest numbers, I'm evaluating the performance of the unit when used as expected. You also need not do the test as many times as I did; only enough that you feel it demonstrates the performance of your unit. If you see significant variability, that's sufficient. I did not, and thus I needed more data points to establish the lack thereof.

By the way, as I mentioned, I have used what I know to be 'best practices' for this test. I specifically do not wish to artificially increase the spring pressure on the terminals for the test, and most definitely do not believe touching the device under test during the test would be 'best practice', as it applies to the objective of this test. I believe both would be counterproductive in this case. I do not wish to make the numbers look better than they are.

Similar threads

- Replies

- 31

- Views

- 2K