Tofty

Enlightened

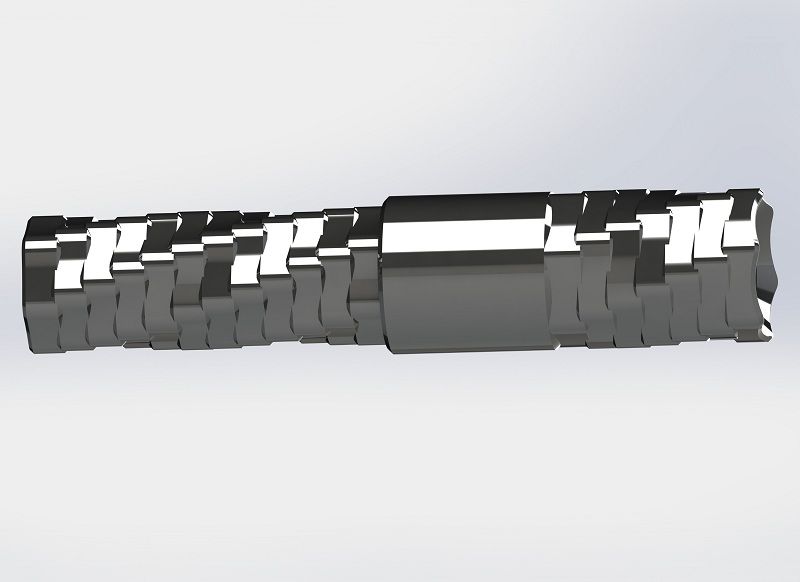

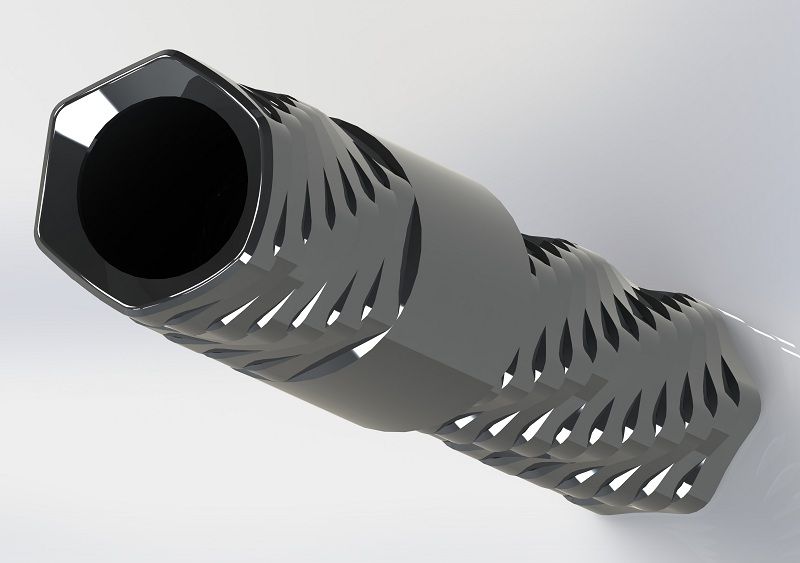

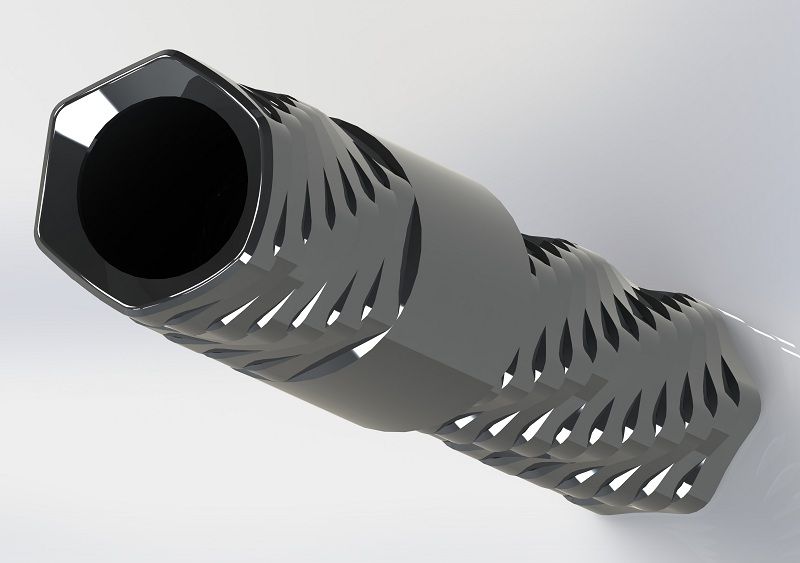

It's not been the easiest build ever but here it is, my fully working 3D printed silver torch:

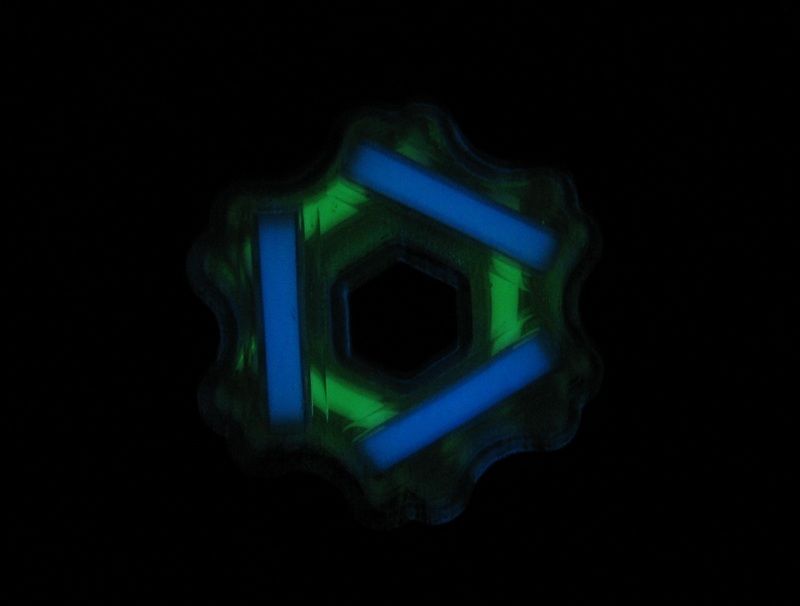

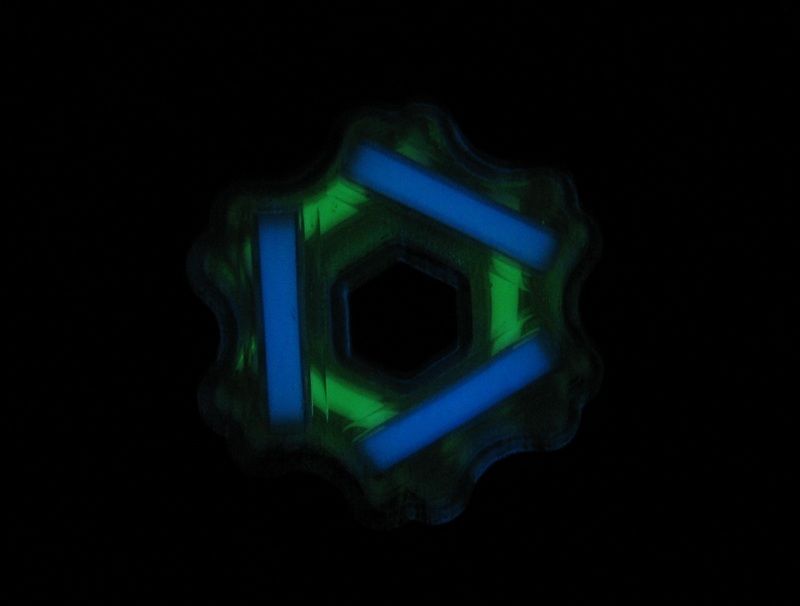

The tritium vials are 6x2mm.

The lights specifications are:

an XM-L U2 mounted on a 16mm copper board,

shining through a Carclo 10003 20mm TIR lens,

driven by an uprated 3.04A 8xACM7135 multi-mode driver set to low/medium/high with memory,

powred by an AW IMR 16340 high discharge cell,

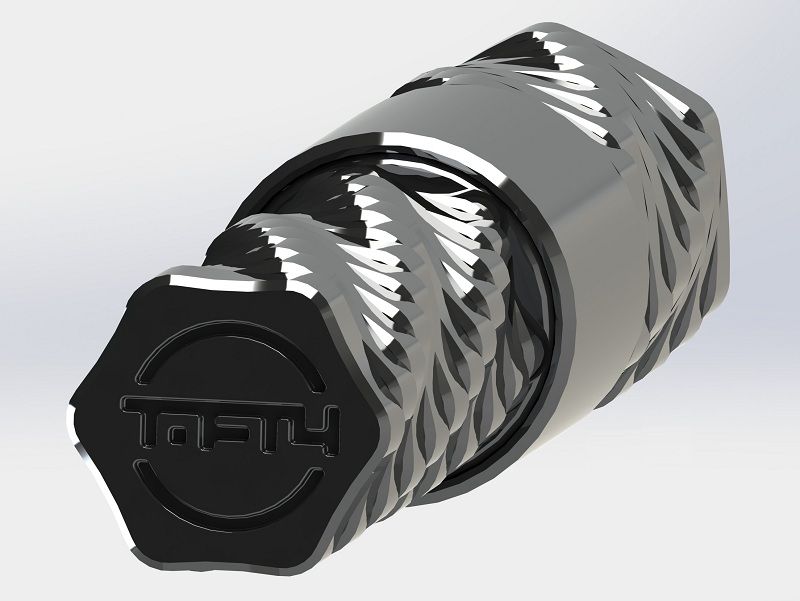

controlled by a tail mounted mcclicky switch and extra sprung silver switch cover.

I probably won't make nine hundred and ninety nine of them though.

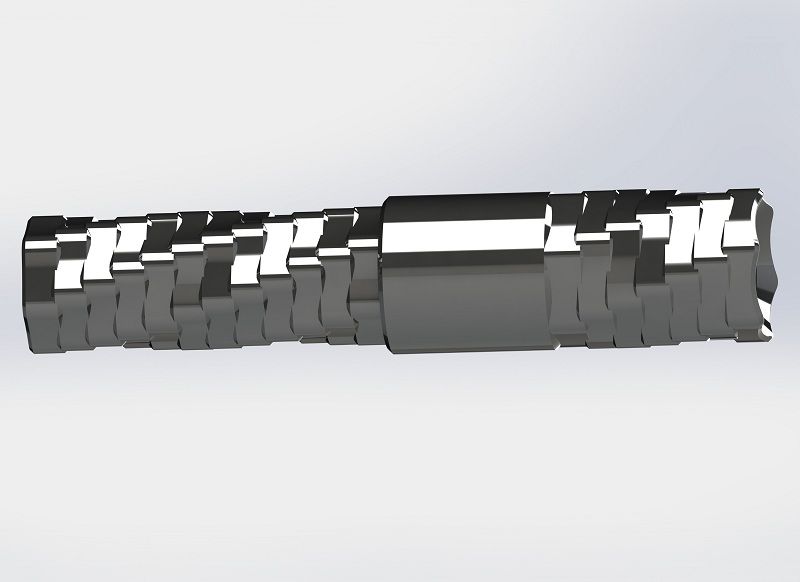

Threads turned out very well, they are the same 20tpi pitch on the surefire P/C/Z series, about 1.3mm pitch.

A comparison between this and my brass torch with pretty much the same internals.

The only difference is that the brass torch has a T5 tint XM-L rather than the U2 and is not mounted on a copper board, also the silver torches' LED board is screwed into place with thermal paste as the interface while the brass torch has it's LED board glued in place.

I'm really happy with the way this light has turned out and may well be the only completely 3D printed metal torch host ever made....so far.

The head get quite hot, very fast but stabilizes at a temperature thats not too hot to hold

I suppose this is proof of the very efficient thermal path, in fact i can't think of much that could improve it apart from a silver LED board.

Next step is to send it off to get hallmarked as it would be illegal in the UK to sell this toch as silver without such certification, not that i plan to ever sell it.

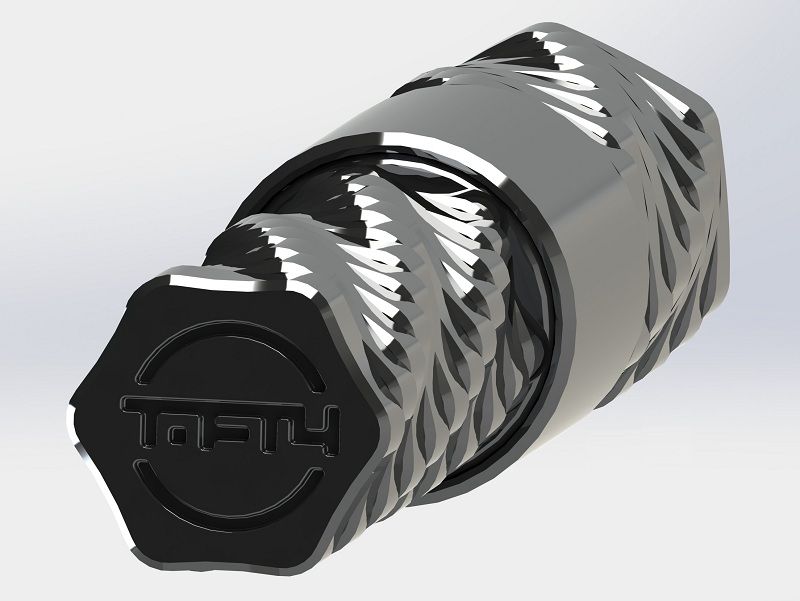

I've also been designing a small AAA silver host:

Any comments welcome, thanks for looking.

The tritium vials are 6x2mm.

The lights specifications are:

an XM-L U2 mounted on a 16mm copper board,

shining through a Carclo 10003 20mm TIR lens,

driven by an uprated 3.04A 8xACM7135 multi-mode driver set to low/medium/high with memory,

powred by an AW IMR 16340 high discharge cell,

controlled by a tail mounted mcclicky switch and extra sprung silver switch cover.

I probably won't make nine hundred and ninety nine of them though.

Threads turned out very well, they are the same 20tpi pitch on the surefire P/C/Z series, about 1.3mm pitch.

A comparison between this and my brass torch with pretty much the same internals.

The only difference is that the brass torch has a T5 tint XM-L rather than the U2 and is not mounted on a copper board, also the silver torches' LED board is screwed into place with thermal paste as the interface while the brass torch has it's LED board glued in place.

I'm really happy with the way this light has turned out and may well be the only completely 3D printed metal torch host ever made....so far.

The head get quite hot, very fast but stabilizes at a temperature thats not too hot to hold

I suppose this is proof of the very efficient thermal path, in fact i can't think of much that could improve it apart from a silver LED board.

Next step is to send it off to get hallmarked as it would be illegal in the UK to sell this toch as silver without such certification, not that i plan to ever sell it.

I've also been designing a small AAA silver host:

Any comments welcome, thanks for looking.