BillyNoMates

Newly Enlightened

I've been absent from CPF for quite a while, but now that the dark nights are approaching, I thought I would share my latest project - a single light with a low-beam and high-beam. I do plenty of commuting and I find I am always adjusting the position of the light to fit the road conditions - aimed low in town and on roads to keep the main beam out of driver's (or other cyclist's) eyes, but closer to horizontal on the unlit rural roads.

For a while I've wanted to have the best of both worlds - one light with a dip-beam for roads and towns, plus a big main-beam for dark lonely sections (to keep the ghosts away). Having one beam shape with different levels doesn't really do the job - even a reduced power LED light can still be anti-social if it is being shone in someone's eyes.

To do this I've decided to build a rather large unit based on 19-xpg's. I'll use 7 to construct the dip-beam and 12 to form the main beam. Each LED will have its own aspheric lens and the relative position of the LED to the lens centre will influence the direction in which the image of the LED is projected. The LEDs are placed close to the focal point of the lens in order to create a sharp cut-off which will allow the dip-beam to be set up to prevent excessive spill reaching on-coming traffic. Each of the 7 LEDs used to form the dip-beam will point in a specific direction in order to build the desired beam shape. Main beam is formed by 12 LEDs all projecting in the same direction.

It is a grand plan with the potential to put out some serious lumens (19 xpgs at 1.5A each). With this number of LEDs available I don't need to choose ultra-high output cool-white tints, so I've opted for the softer warm tints which I prefer.

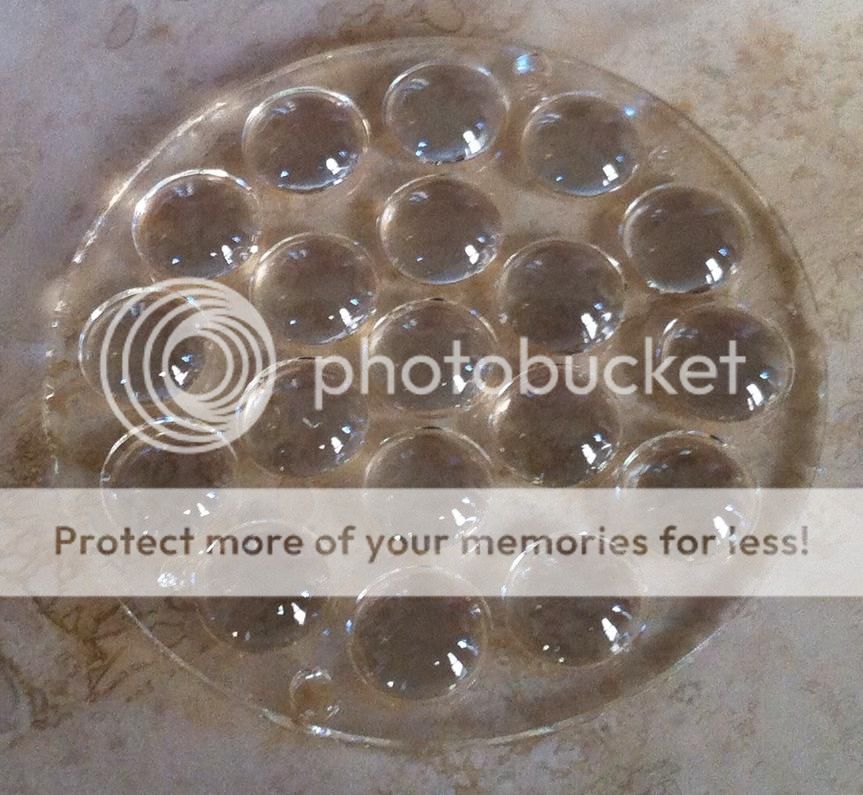

The first part of this build is focused the lens (sorry for the pun). Mounting 19 lenses was proving to be rather tedious, so I turned to a custom home-cast compound lens: 19 little (12mm) aspherics arranged in concentric circles. Here is a picture.

This lens isn't small - the outside diameter is 70mm.

It was made by making a mould of a 12mm aspheric lens then copying it multiple times until I had enough lenses. These were then arranged in a pre-drilled template to make the final mould. The lens was then cast in this mould using clear casting resin with the same refractive index as the original lens. The finished product is not quite projection quality, but it is possible to obtain a projected image of the LED with a well-defined edge, giving me the sharp cut-off I was after.

I'll post more details as I progress - next installment is the housing. Drawings are done and with a local machine shop.

For a while I've wanted to have the best of both worlds - one light with a dip-beam for roads and towns, plus a big main-beam for dark lonely sections (to keep the ghosts away). Having one beam shape with different levels doesn't really do the job - even a reduced power LED light can still be anti-social if it is being shone in someone's eyes.

To do this I've decided to build a rather large unit based on 19-xpg's. I'll use 7 to construct the dip-beam and 12 to form the main beam. Each LED will have its own aspheric lens and the relative position of the LED to the lens centre will influence the direction in which the image of the LED is projected. The LEDs are placed close to the focal point of the lens in order to create a sharp cut-off which will allow the dip-beam to be set up to prevent excessive spill reaching on-coming traffic. Each of the 7 LEDs used to form the dip-beam will point in a specific direction in order to build the desired beam shape. Main beam is formed by 12 LEDs all projecting in the same direction.

It is a grand plan with the potential to put out some serious lumens (19 xpgs at 1.5A each). With this number of LEDs available I don't need to choose ultra-high output cool-white tints, so I've opted for the softer warm tints which I prefer.

The first part of this build is focused the lens (sorry for the pun). Mounting 19 lenses was proving to be rather tedious, so I turned to a custom home-cast compound lens: 19 little (12mm) aspherics arranged in concentric circles. Here is a picture.

This lens isn't small - the outside diameter is 70mm.

It was made by making a mould of a 12mm aspheric lens then copying it multiple times until I had enough lenses. These were then arranged in a pre-drilled template to make the final mould. The lens was then cast in this mould using clear casting resin with the same refractive index as the original lens. The finished product is not quite projection quality, but it is possible to obtain a projected image of the LED with a well-defined edge, giving me the sharp cut-off I was after.

I'll post more details as I progress - next installment is the housing. Drawings are done and with a local machine shop.