Re: Custom Machined Light Housings

Hey barry

To answer your question, yes i'd be running each led off a separate driver.

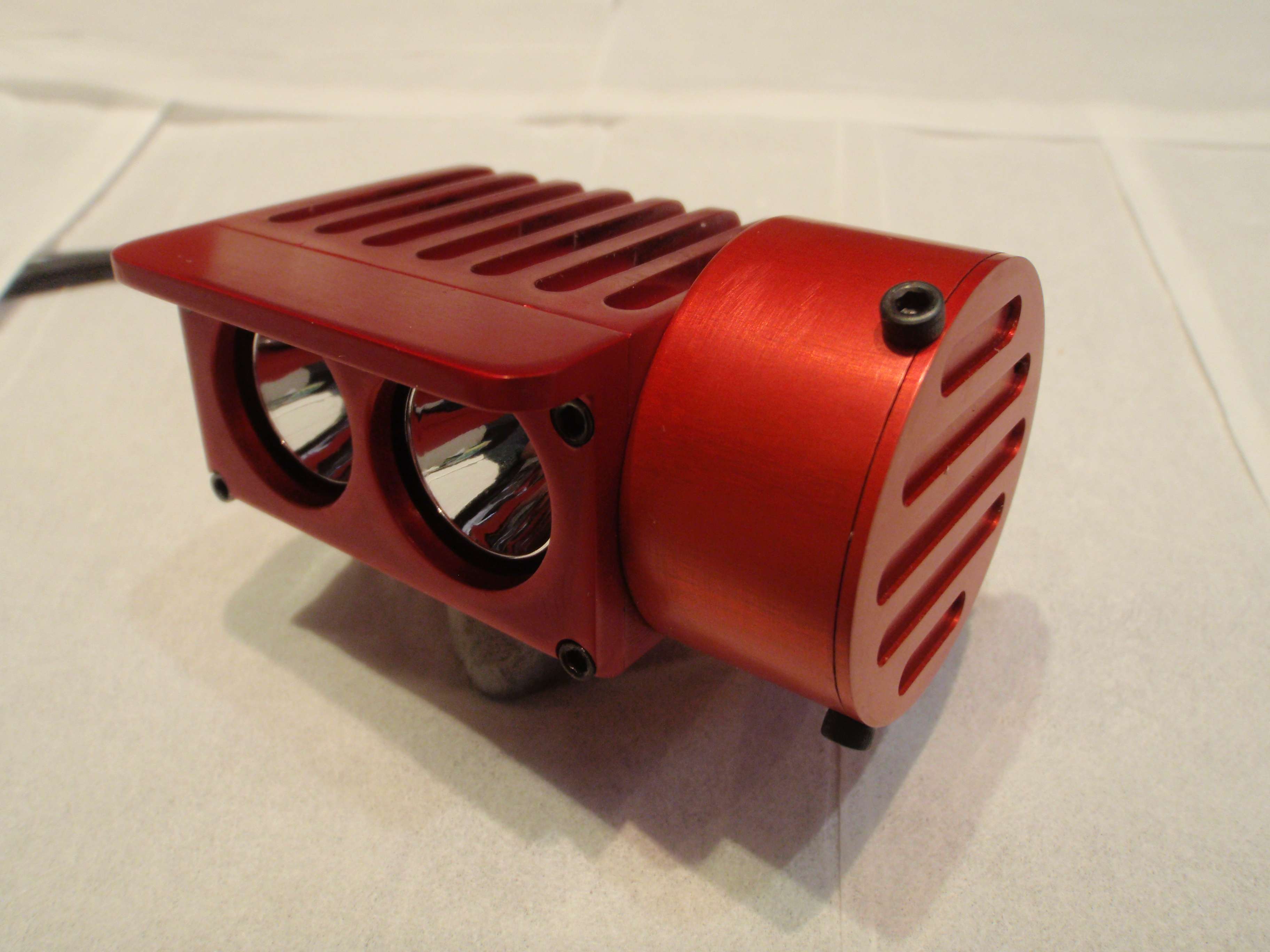

First, i'll just say that to be honest, your design, as is, would work for me so long as there was some sort of 'base' to put the led stars on, since yours is a tube completely through.

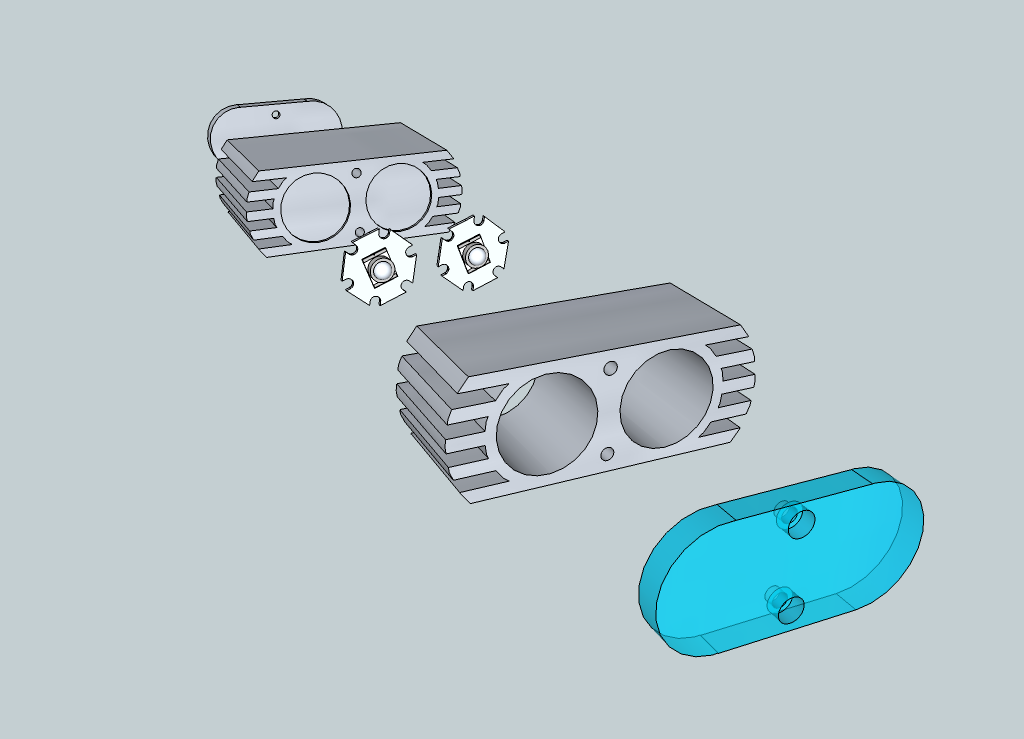

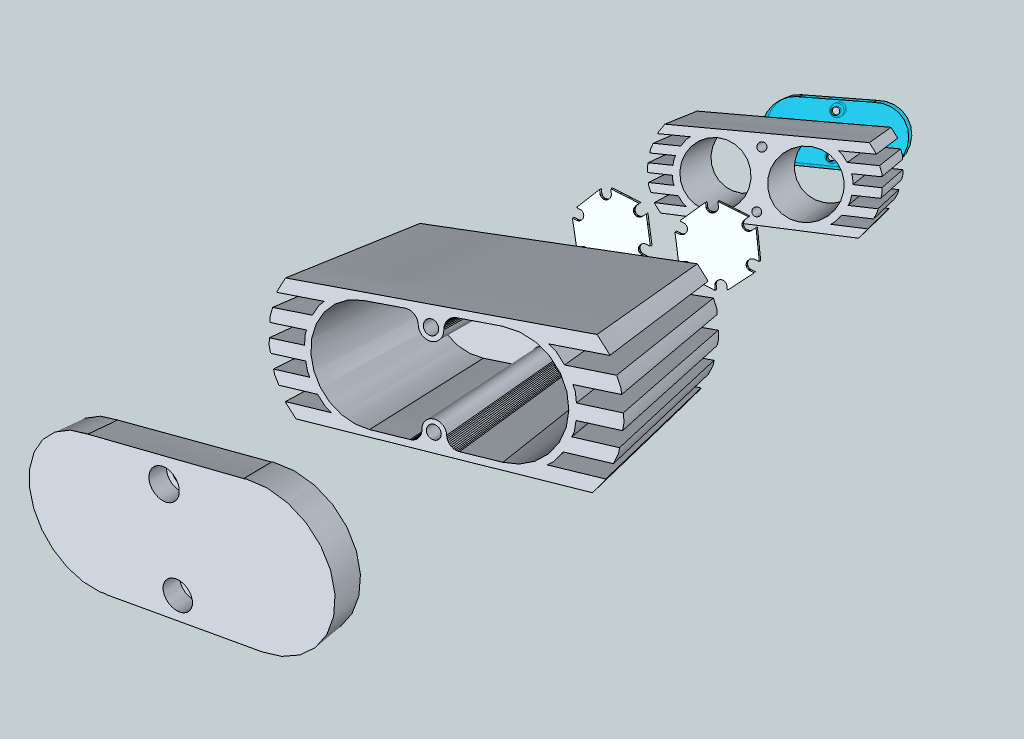

I put this together quickly after work, what are your thoughts? I know it is fairly complex, but there are quite a few areas that can be cheapened. The bevel on the outer edge can go happily, and the depressions for seating the stars is optional. The inside edges of the fins are only shaped with the curve for ease of drawing, i imagine machined they'd just get the shape of the toolhead, which is fine.

I havent put the spaces for the leds/switches in the back panel as i figured they'd be apparent. I'd probably keep the switching mechanism on the light for now, but since its modularish, you could really just remachine a back end if you wanted switches elsewhere and less bulk on the light.

If you think this design is too easy (if so, im jealous) then it would be pretty awesome to bring the side fins 5mm forward and back so the panels fit -into- the block rather than sitting on the outside.

I have the sketchup file if you want to have a poke around. I've really only guessed at some measurements. I assumed 3mm bolts to hold it together, and 27mm - 28mm to hold the star and optic. (cant remember optic length, i assumed 25mm). gave 40mm of depth for rear components, didnt mark in the wiring holes for the leds as i would probably do them last minute with a dremel, little 1mm holes in the star gaps. The whole thing is roughly 70x70x27mm.

I also kind of did this in a way that you could machine a long bar of material, cut the sections apart, then take out the internal areas, should you want to build multiple.