You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom Machined Light Housings + Other Hobby Machinists Bicycle Light Services

- Thread starter Michael.su

- Start date

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

Flamingtaco

Newly Enlightened

- Joined

- Feb 26, 2008

- Messages

- 31

Don't know about anyone else, but I am tired of battery packs costing more than half of a light kit. This is the reason that I've never bought a decent lamp kit. I like building kits, but there are some realy nice kits with great features and controls out there.

Then I see the cost of replacement batteries. Ugh.

What I really want, more than anything, is an aluminum battery housing for loose batteries! Here's the skinny:

4x18650's

Cap at one end secures with a single bolt in the center (preferred)

Both caps tapped with four holes for standoffs for circuit boards

Cap at the other end... drilled for a cable gland (or two). Extra room under the circuit board for LED driver(s).

Two external taps on the side permit bagless mounting to bars/frame. Good airflow for housings serving as sinks for drivers. Maybe fin the cap at the LED driver (s) end for extra thermal capacity?

Pin or...? the caps so they are installed the same orientation after each battery swap.

Insets for rubber o-rings (cap seals)?

I can draw images this weekend if more detail on what I am thinking is needed.

A void in battery housings has always existed, I am surprised we have come this far, yet no one has stepped up. I just bought the Fenix BT20 because it allows use of loose 18650's. Finally, a non-chinagoods company is listening. There are two plastic housings available from the chinagoods sellers, one even has a thumbscrew cap, but it is 1s4p. I think most DIY's need 2s2p, 4s1p, 3s2p, etc. With one 4x18650 housing kit we can do four battery configurations (1s4p, 2s2p, 3s1p, 4s1p), by etching our own blank boards. And I'm sure someone would step up and provide pre-etched boards, pre-assembled boards, etc.

Thanks for consideration!

David

Then I see the cost of replacement batteries. Ugh.

What I really want, more than anything, is an aluminum battery housing for loose batteries! Here's the skinny:

4x18650's

Cap at one end secures with a single bolt in the center (preferred)

Both caps tapped with four holes for standoffs for circuit boards

Cap at the other end... drilled for a cable gland (or two). Extra room under the circuit board for LED driver(s).

Two external taps on the side permit bagless mounting to bars/frame. Good airflow for housings serving as sinks for drivers. Maybe fin the cap at the LED driver (s) end for extra thermal capacity?

Pin or...? the caps so they are installed the same orientation after each battery swap.

Insets for rubber o-rings (cap seals)?

I can draw images this weekend if more detail on what I am thinking is needed.

A void in battery housings has always existed, I am surprised we have come this far, yet no one has stepped up. I just bought the Fenix BT20 because it allows use of loose 18650's. Finally, a non-chinagoods company is listening. There are two plastic housings available from the chinagoods sellers, one even has a thumbscrew cap, but it is 1s4p. I think most DIY's need 2s2p, 4s1p, 3s2p, etc. With one 4x18650 housing kit we can do four battery configurations (1s4p, 2s2p, 3s1p, 4s1p), by etching our own blank boards. And I'm sure someone would step up and provide pre-etched boards, pre-assembled boards, etc.

Thanks for consideration!

David

PCC

Flashlight Enthusiast

I've thought about buying ready made 2X18650 series battery holders, gluing two together, then making a waterproof housing for it. It would be plastic, though. 2S2P or 4S is possible with this setup.

Flamingtaco

Newly Enlightened

- Joined

- Feb 26, 2008

- Messages

- 31

I've thought about buying ready made 2X18650 series battery holders, gluing two together, then making a waterproof housing for it. It would be plastic, though. 2S2P or 4S is possible with this setup.

I put a 4x holder in a pelican 1020, has room to add a 2x. Easy battery access and very durable, but I want to locate the driver away from the LEDs now without having a fourth housing, and also want to lose the bulk of the pelican.

Flamingtaco

Newly Enlightened

- Joined

- Feb 26, 2008

- Messages

- 31

Sorry, posting troubles...

Last edited:

Michael.su

Newly Enlightened

- Joined

- Sep 9, 2009

- Messages

- 9

Don't know about anyone else, but I am tired of battery packs costing more than half of a light kit. This is the reason that I've never bought a decent lamp kit. I like building kits, but there are some realy nice kits with great features and controls out there.

Then I see the cost of replacement batteries. Ugh.

What I really want, more than anything, is an aluminum battery housing for loose batteries! Here's the skinny:

4x18650's

Cap at one end secures with a single bolt in the center (preferred)

Both caps tapped with four holes for standoffs for circuit boards

Cap at the other end... drilled for a cable gland (or two). Extra room under the circuit board for LED driver(s).

Two external taps on the side permit bagless mounting to bars/frame. Good airflow for housings serving as sinks for drivers. Maybe fin the cap at the LED driver (s) end for extra thermal capacity?

Pin or...? the caps so they are installed the same orientation after each battery swap.

Insets for rubber o-rings (cap seals)?

I can draw images this weekend if more detail on what I am thinking is needed.

A void in battery housings has always existed, I am surprised we have come this far, yet no one has stepped up. I just bought the Fenix BT20 because it allows use of loose 18650's. Finally, a non-chinagoods company is listening. There are two plastic housings available from the chinagoods sellers, one even has a thumbscrew cap, but it is 1s4p. I think most DIY's need 2s2p, 4s1p, 3s2p, etc. With one 4x18650 housing kit we can do four battery configurations (1s4p, 2s2p, 3s1p, 4s1p), by etching our own blank boards. And I'm sure someone would step up and provide pre-etched boards, pre-assembled boards, etc.

Thanks for consideration!

David

Interesting concept. You would definitely need some sketches at least to start with. It's not a bad idea to model everything in a solid modeler (even something free like sketch-up would give everyone a better idea) I haven't been doing much with any of this recently, I've been really busy with life the past couple of years...

The lights that I've made are still alive and being used as often as possible

I'll help out in any way I can but I don't have much machine time available right now. There are some other people in this thread that have offered up their services also so maybe they are more available.

As everyone knows, The Chinese stuff is just so cheap it's hard to justify the cost of time and $$ for custom machined stuff unless you really have a game changing idea or you just like to build and tinker (I fall in the build/tinker category

shoot me a message if I can help with design. I have software and measuring tools available to me and I also have 18650 batteries for measurements. You will need to figure out the form factor stuff on the circuit boards that you are referring to as well to get a workable concept. I would consider making myself one of these as well for my setups if we can come up with a workable design. I would actually like one with just the batteries so it's a more flexible design when different drivers are needed.

-Mike

kuksul08

Enlightened

Totally agree man, the battery packs and housings currently available are junk. I've seen way too many of them fall apart.

Flamingtaco

Newly Enlightened

- Joined

- Feb 26, 2008

- Messages

- 31

Interesting concept. You would definitely need some sketches at least to start with. It's not a bad idea to model everything in a solid modeler

-Mike

I will draw somewthing up this weekend. Don't know if I can use a modeler (old pc's), but I can definately do design blueprints.

I would not consider this something to compete with the chinese stuff. For $20 you can get a plastic box with a single wing-nut to open, just by two if you need an 8v setup. I am thinking of this as more of a buy it once kind of thing, ultra-durable, with the ability to have multiple contact boards so the owner can modify the housing to suit different voltage needs. Not a case for weight weenies, although not neccessarily a tank, either.

brad72

Newly Enlightened

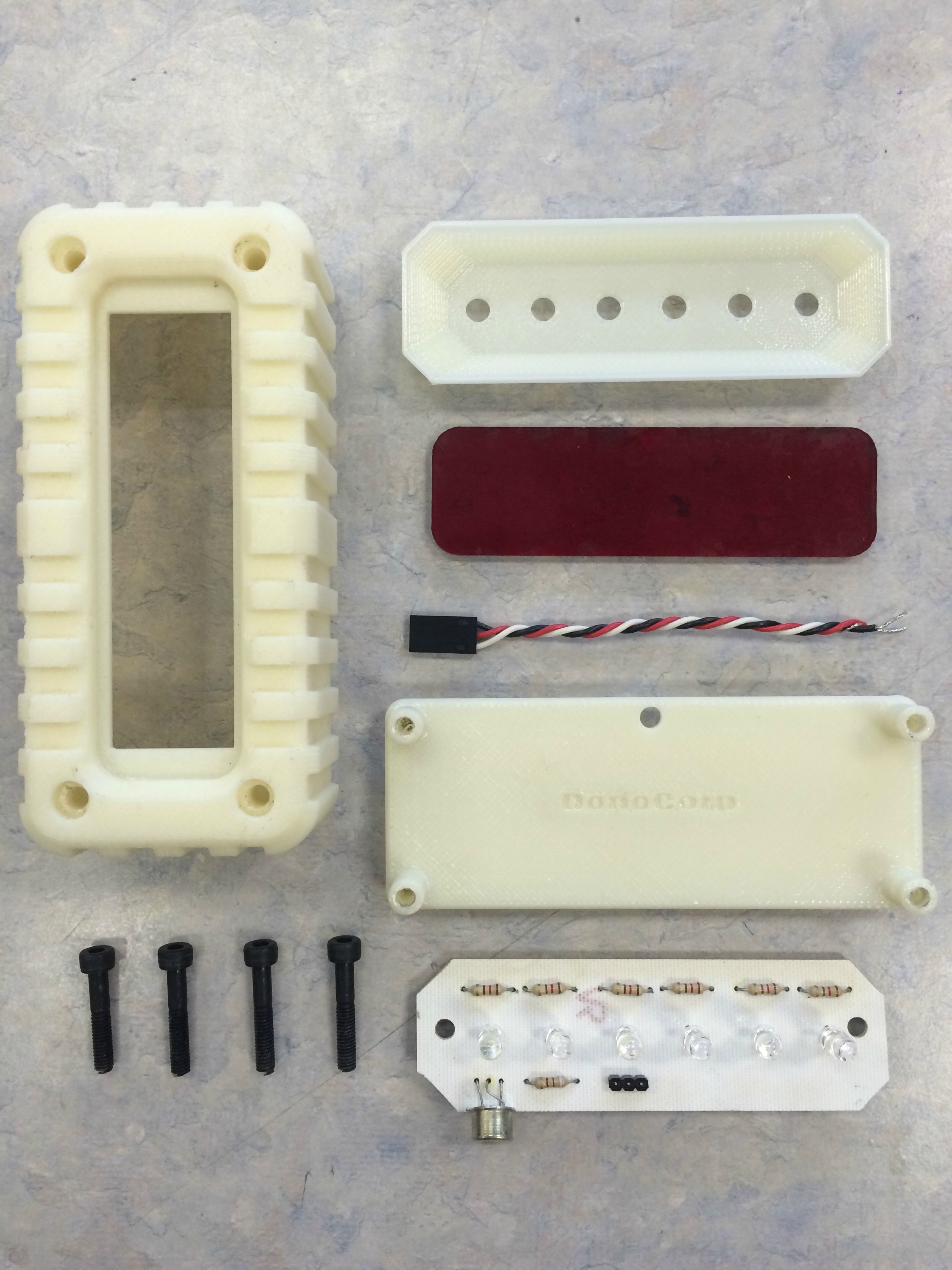

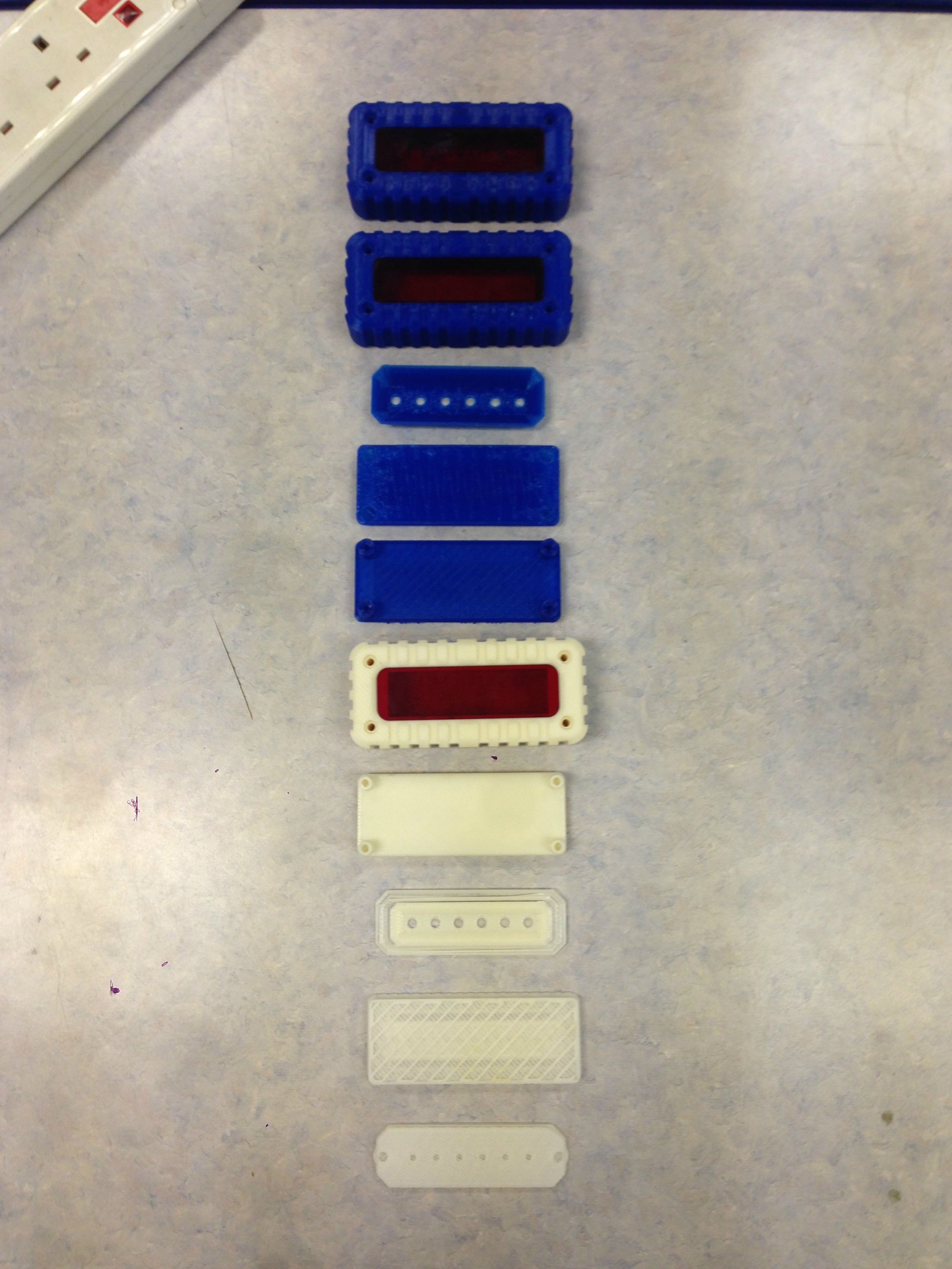

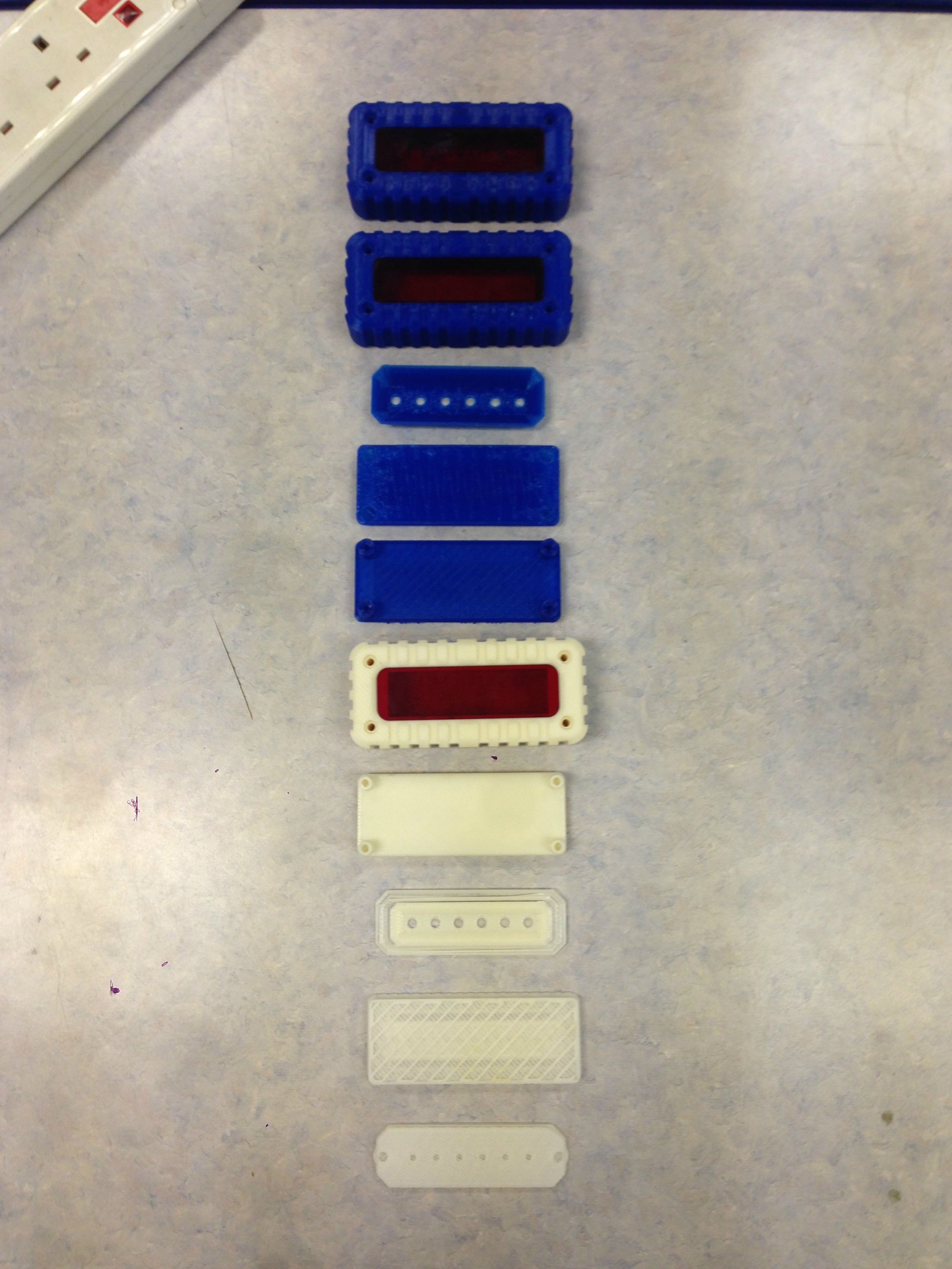

I have started to make some 3D printed battery cases to suit 18650 cells. The battery terminals arrived a week or so ago which means I can now adjust the design to suit them. The ones below were a low quality mock up for proof of concept and the case color can be whatever you want. The best part is you can have a 2s1p, 1s2p, 2s2p, 3s1p, or 4s1p, so can cover all flavours.

Flamingtaco

Newly Enlightened

- Joined

- Feb 26, 2008

- Messages

- 31

Double 18650 containers is my second thought, except with sealed external contacts and cases that can lock together to form either parallel connections just by snapping them together. Take as few or as many as your ride needs. If you don't mind my asking, what kind of cost is associated with 3D printing at a retailer?

Flamingtaco

Newly Enlightened

- Joined

- Feb 26, 2008

- Messages

- 31

Spent most of Saturday in birthday mode, so spare time Sunday went to spec'ing supply parts and running 20 or so draft revisions through my head. I've got the layout largely worked out, need to go to pen and paper to lay down the fitment.

If the cost of milling aluminum caps turns out to be prohibitive, I can mill them out of ABS and attach heatsinks for drivers.

If the cost of milling aluminum caps turns out to be prohibitive, I can mill them out of ABS and attach heatsinks for drivers.

Flamingtaco

Newly Enlightened

- Joined

- Feb 26, 2008

- Messages

- 31

Re: Custom Machined Light Housings

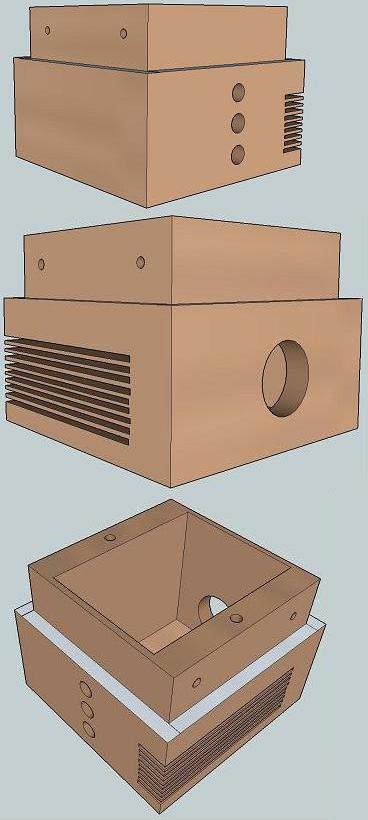

Ok, here's part of the deal, the bottom cap.It is 2 inch square by about 1.25 inch tall. One large hole for a switch, three smaller ones on the opposite side for cable nuts. The other holes are for bolts. A driver can be attached inside, behind the finned area. I figured on using 2 inch square bar stock since it is easily availabe in small quantities. The top will be maybe 1/2 inch tall, similar in design except no large holes for components. Anyone capable of milling these parts? I would like to get a ballpark on cost before I continue spec'ing the parts in aluminum.

Ok, here's part of the deal, the bottom cap.It is 2 inch square by about 1.25 inch tall. One large hole for a switch, three smaller ones on the opposite side for cable nuts. The other holes are for bolts. A driver can be attached inside, behind the finned area. I figured on using 2 inch square bar stock since it is easily availabe in small quantities. The top will be maybe 1/2 inch tall, similar in design except no large holes for components. Anyone capable of milling these parts? I would like to get a ballpark on cost before I continue spec'ing the parts in aluminum.

brad72

Newly Enlightened

Double 18650 containers is my second thought, except with sealed external contacts and cases that can lock together to form either parallel connections just by snapping them together. Take as few or as many as your ride needs. If you don't mind my asking, what kind of cost is associated with 3D printing at a retailer?

Not expensive at in terms of material but the initial outlay of the printer is about $1,000. The best part is any design you can draw up in cad, the printer will be able to print. The only design constraints are the wall thicknesses.

Flamingtaco

Newly Enlightened

- Joined

- Feb 26, 2008

- Messages

- 31

Not expensive at in terms of material but the initial outlay of the printer is about $1,000. The

I already work with fiberglass, carbon fiber, and resins (larger pieces). Not enough money or time, another lifetime, maybe.

Are you still interested in machining aluminum parts? If not, can you clue me in to approximately what I should expect some one-off pieces of this size and complexity to cost?

Thanks,

David

Last edited:

Hi guys

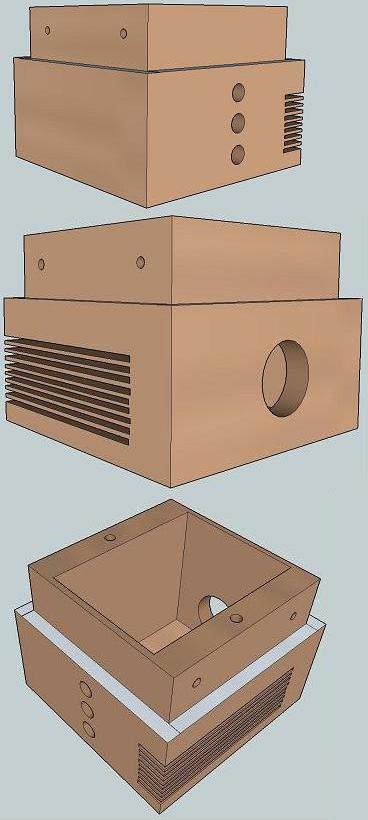

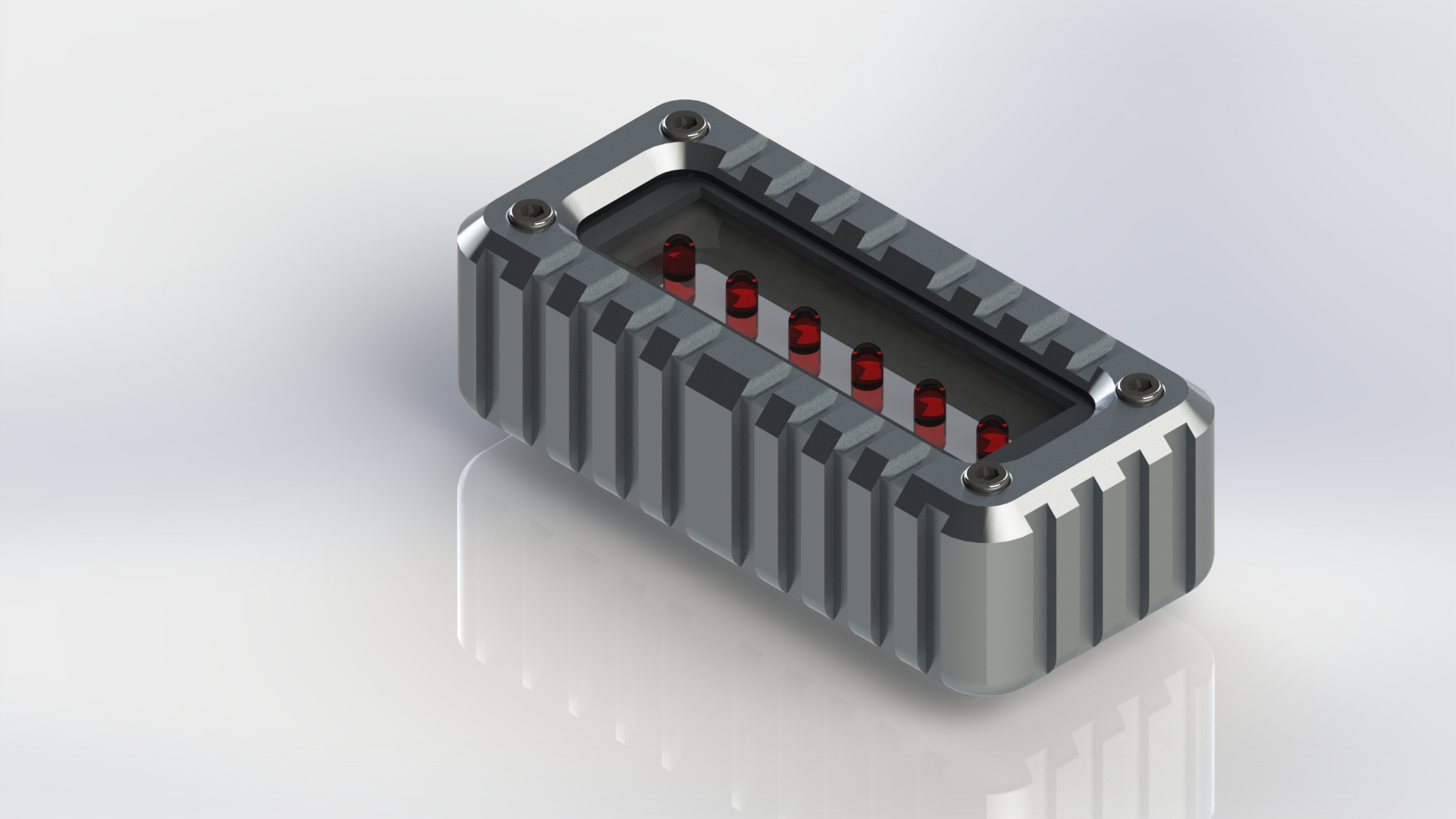

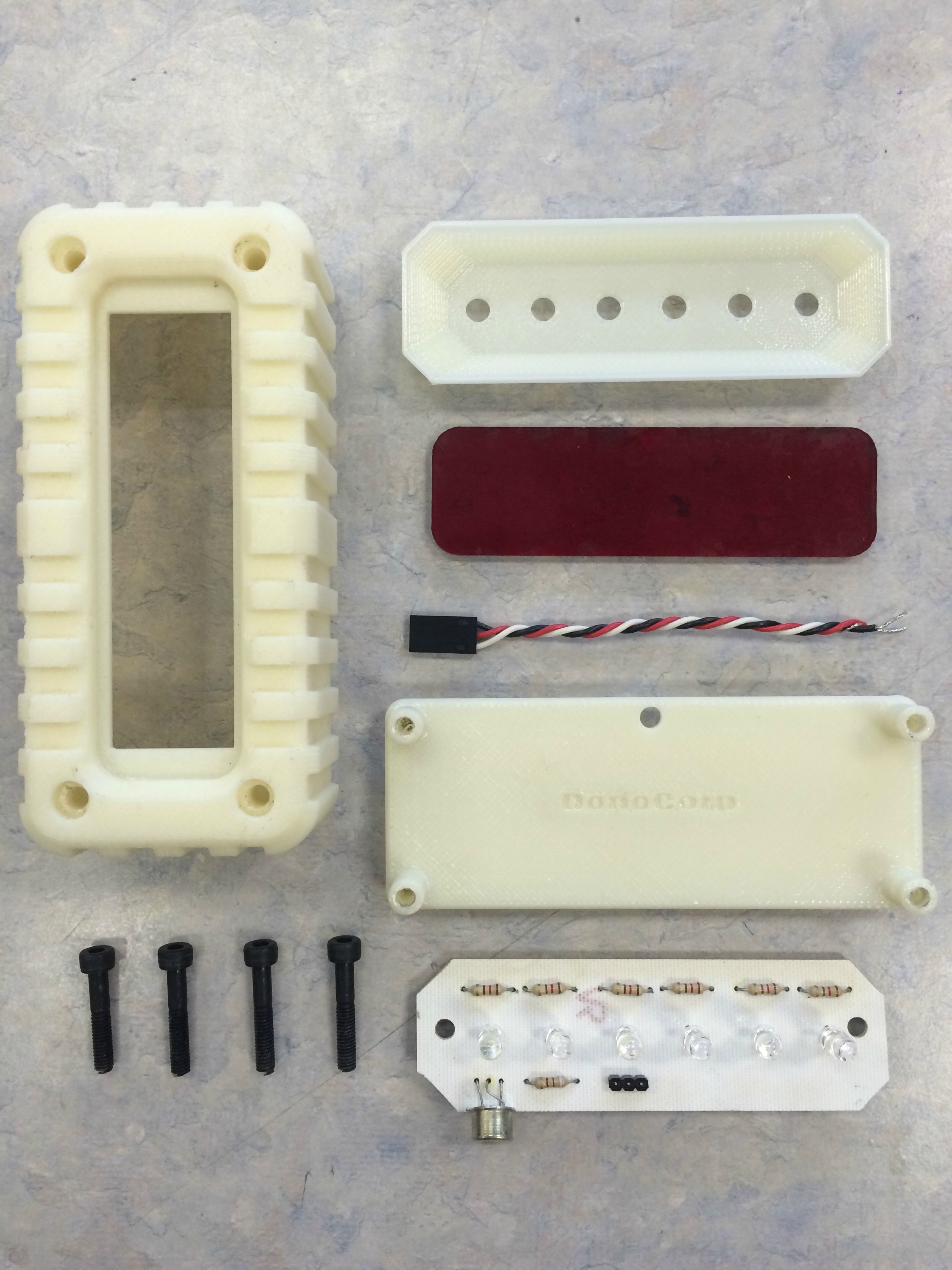

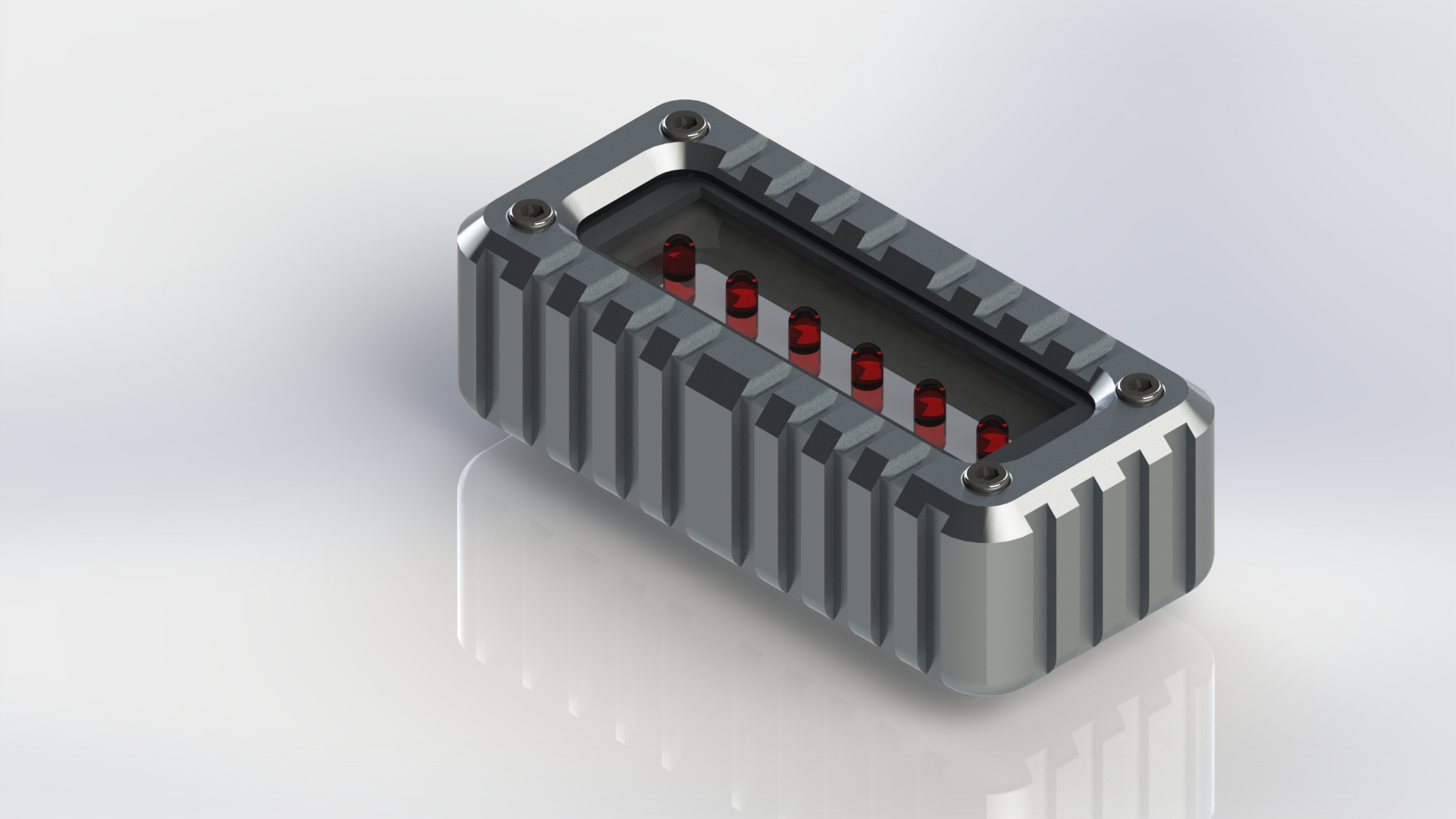

I'm currently studying a Level 3 BTEC in engineering, and have decided as my year 2 project to make a prototype bicycle light. Below I have some pictures of the initial 3D printed light, as well as some SolidWorks models.

I'm simply looking for some advice and, hopefully constructive, criticism. Feel free to ask any questions and explain things in more detail.

I'm currently studying a Level 3 BTEC in engineering, and have decided as my year 2 project to make a prototype bicycle light. Below I have some pictures of the initial 3D printed light, as well as some SolidWorks models.

I'm simply looking for some advice and, hopefully constructive, criticism. Feel free to ask any questions and explain things in more detail.

Steve K

Flashlight Enthusiast

always good to see someone playing around with bike lights!

Can you tell us what the design goals were? i.e. what specification are you trying to satisfy?

From looking at the images, the housing seems bigger than is needed for a handful of 5mm LEDs.

The use of leaded components strikes me as unusual. I'm much more used to using surface mount parts. I will say that if you are committed to using 5mm LEDs, then using leaded resistors, transistor (where did you find a transistor in a can nowadays?), and connector could be the correct choice. It does let you wave solder everything at once (assuming that this is being designed for mass production).

How well sealed is it against water?

These are just my thoughts. What counts is that you are designing to a specification and optimizing things for that spec.... even if the spec is "make it look cool and make people want to buy it".

Can you tell us what the design goals were? i.e. what specification are you trying to satisfy?

From looking at the images, the housing seems bigger than is needed for a handful of 5mm LEDs.

The use of leaded components strikes me as unusual. I'm much more used to using surface mount parts. I will say that if you are committed to using 5mm LEDs, then using leaded resistors, transistor (where did you find a transistor in a can nowadays?), and connector could be the correct choice. It does let you wave solder everything at once (assuming that this is being designed for mass production).

How well sealed is it against water?

These are just my thoughts. What counts is that you are designing to a specification and optimizing things for that spec.... even if the spec is "make it look cool and make people want to buy it".

beseenlight

Newly Enlightened

- Joined

- Jul 23, 2015

- Messages

- 1

Good design, I like the two led design, it is use lens or Reflector please?

Similar threads

- Replies

- 3

- Views

- 378

Latest posts

-

-

-

For Sale - Flashlight SureFire and some others

- Latest: desert.snake

-

-

-