Which battery size you have in mind Dan?

Great work BTW

Great work BTW

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

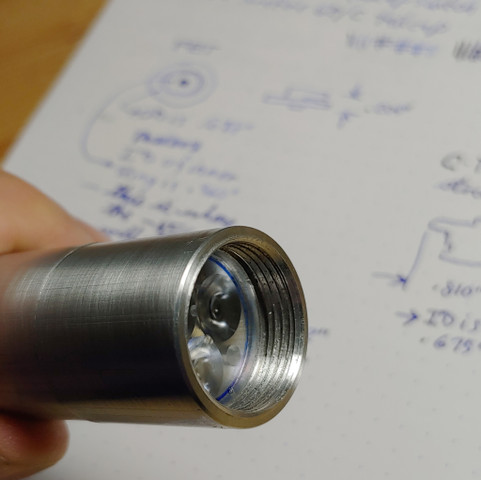

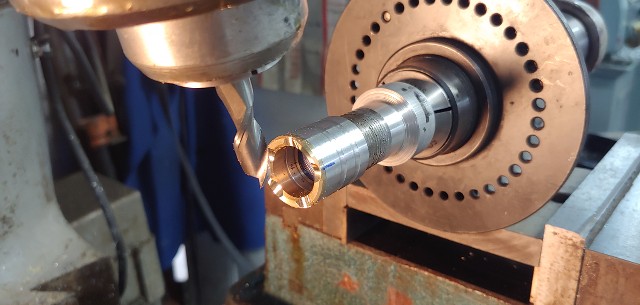

Some progress, some setbacks. Seems like this is the path on this build. Have the 18350 battery tube internals finalized, and worked on the head.

I decided to do a removable bezel, because apparently I like to make things difficult on myself.

Mental note: when ID threading, make sure the bezel is firmly held by the chuck, or it will just unscrew from the body....

HE v11 torch tailcap. A bit too deep, but it worked out well overall.

I am working on a new module for an L5 and ended up reducing the OD to much and cut the top part off that would attach to the bottom of the L5. Doh! So now I have to make it again.