Steve,

Thanks for the clear feedback.

>I gave a try at winding my own transformer last night-and didn't have much success. So your notion to full-wave the AC output might be the best method.

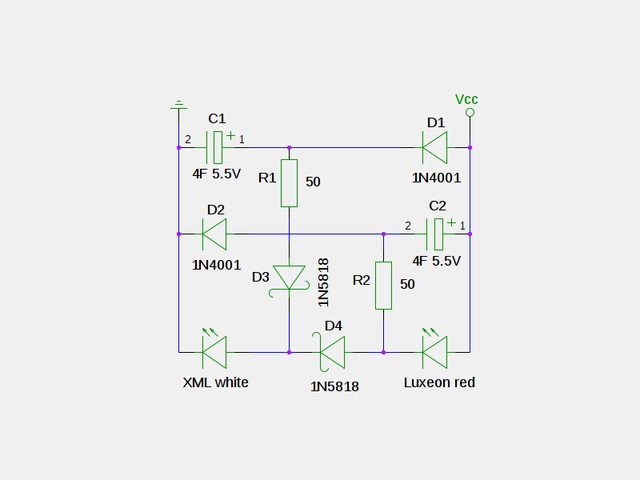

>As far as filtering is concerned: Do you mean adjust the smoothing caps prior to the bridge (smaller value), and adding a shockty pre s. caps?

>I found something last night that might be an option.

-I could full-wave, filter, then maybe get one of the many lux buck drivers as you advised.

-or, I could possibly get the lux driver that is ac/dc, something called a bullet?

I would maybe need to ramp my AC voltage prior though, as the needed baseline voltage is 5vac (max. 35vac).

>The platter? well... without being complicated, it's just like an axial wind turbine setup but rather than a twin rotor, it's a single. And rather than wind, it is my bicycle drive train. Currently setup at 1x1 : 56crank-14drive.

-At 60rpm pedaling, I get about 240 on the cog. Behind the cog, is a steel plate with a circumference axial magnet array.

-It's made of recycled parts, and has a really good output for no magnetic or mechanical friction.

-The number of alternating poles on the platter facing the solenoid is 8, so...

>240rpm=1900hz and 400rpm=3200hz.

>The two solenoids are wired in series with spacing over the magnets that equals both receiving flux simultaneously (or as one coil).

My math isn't exactly pro - but rough estimates are better than none.

hope at least some of that made sence... If I can get a camera, maybe this would make more sence.

Its my poor mans option to not yet having enough $ for a dynamo hub.

cheers!

Thanks for the clear feedback.

>I gave a try at winding my own transformer last night-and didn't have much success. So your notion to full-wave the AC output might be the best method.

>As far as filtering is concerned: Do you mean adjust the smoothing caps prior to the bridge (smaller value), and adding a shockty pre s. caps?

>I found something last night that might be an option.

-I could full-wave, filter, then maybe get one of the many lux buck drivers as you advised.

-or, I could possibly get the lux driver that is ac/dc, something called a bullet?

I would maybe need to ramp my AC voltage prior though, as the needed baseline voltage is 5vac (max. 35vac).

>The platter? well... without being complicated, it's just like an axial wind turbine setup but rather than a twin rotor, it's a single. And rather than wind, it is my bicycle drive train. Currently setup at 1x1 : 56crank-14drive.

-At 60rpm pedaling, I get about 240 on the cog. Behind the cog, is a steel plate with a circumference axial magnet array.

-It's made of recycled parts, and has a really good output for no magnetic or mechanical friction.

-The number of alternating poles on the platter facing the solenoid is 8, so...

>240rpm=1900hz and 400rpm=3200hz.

>The two solenoids are wired in series with spacing over the magnets that equals both receiving flux simultaneously (or as one coil).

My math isn't exactly pro - but rough estimates are better than none.

hope at least some of that made sence... If I can get a camera, maybe this would make more sence.

Its my poor mans option to not yet having enough $ for a dynamo hub.

cheers!

Last edited: