LLCoolBeans

Flashlight Enthusiast

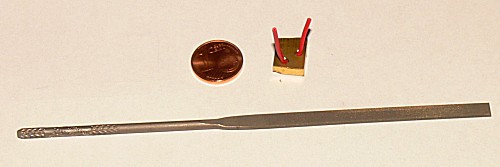

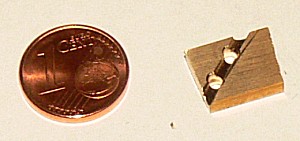

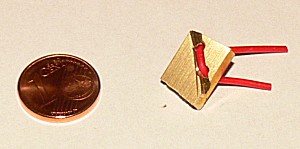

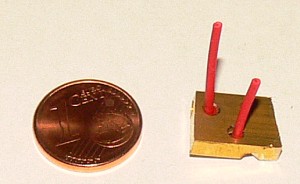

I intend to use thermal compound to attach the body of the emitter to the riser. Once that is centered I'll solder the emitter legs directly to the riser to make the jumper connection. Then I'll solder a couple of 24ga wires to the airborne legs for the positive and negative connections. After that's done, press the emitter into place smear everything with compound and insert heat sink.

This is my first modding project, so if I'm doing something wrong please speak up.

Thanks

This is my first modding project, so if I'm doing something wrong please speak up.

Thanks