MoreGooder

Newly Enlightened

- Joined

- Jan 1, 2010

- Messages

- 75

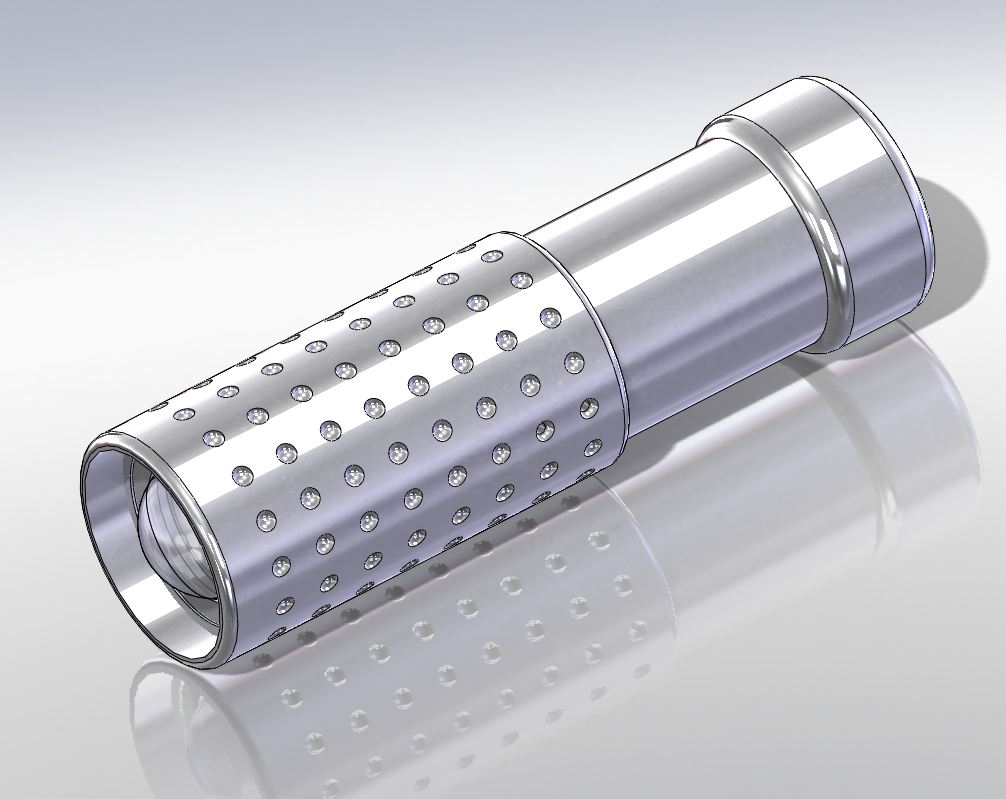

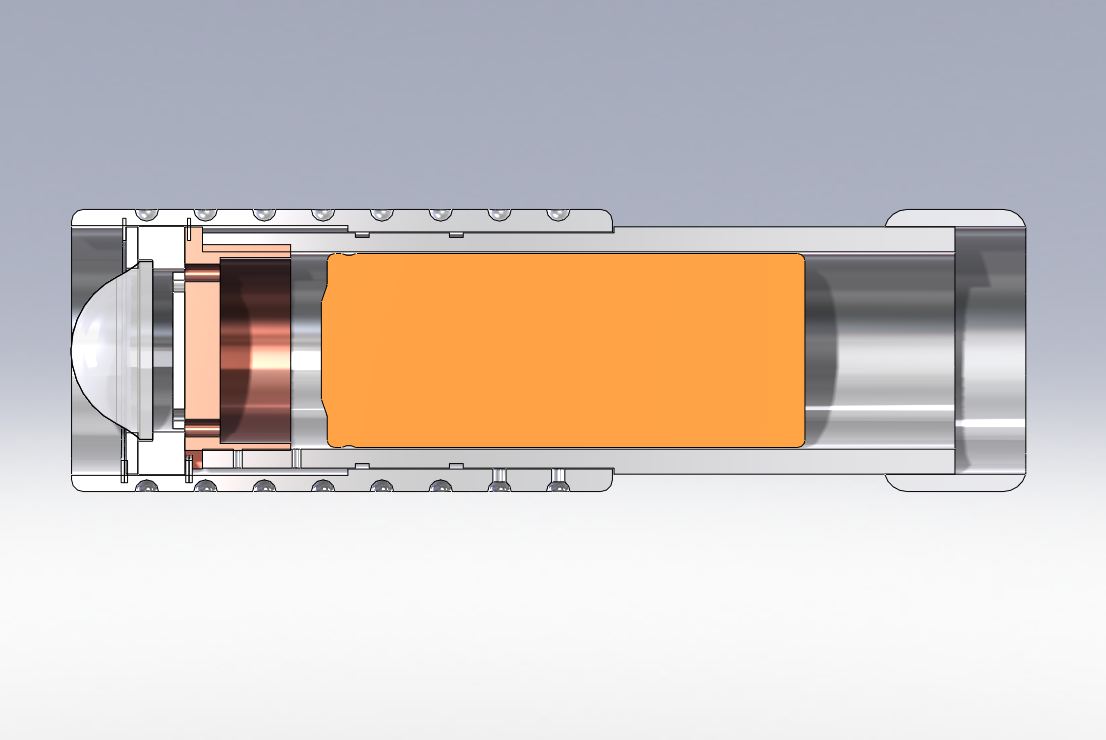

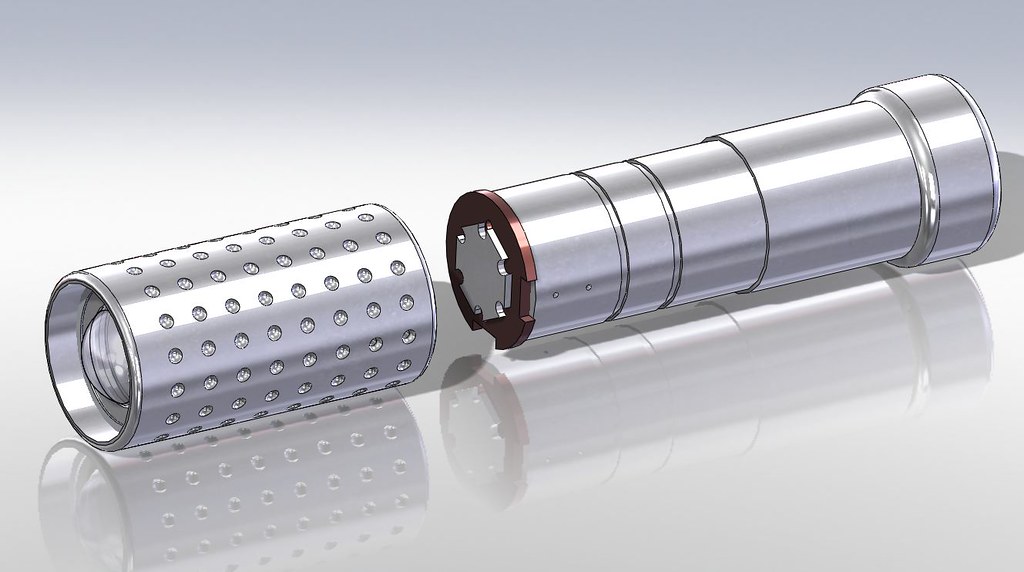

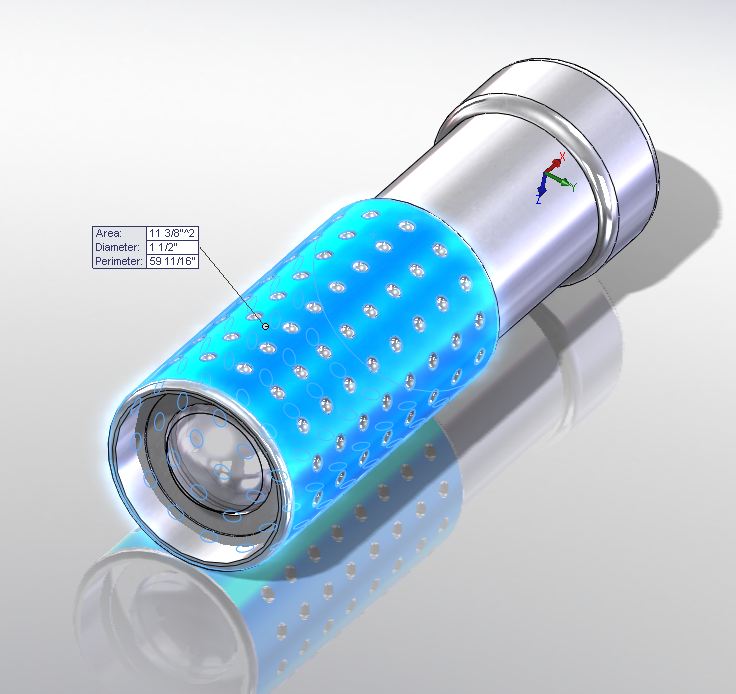

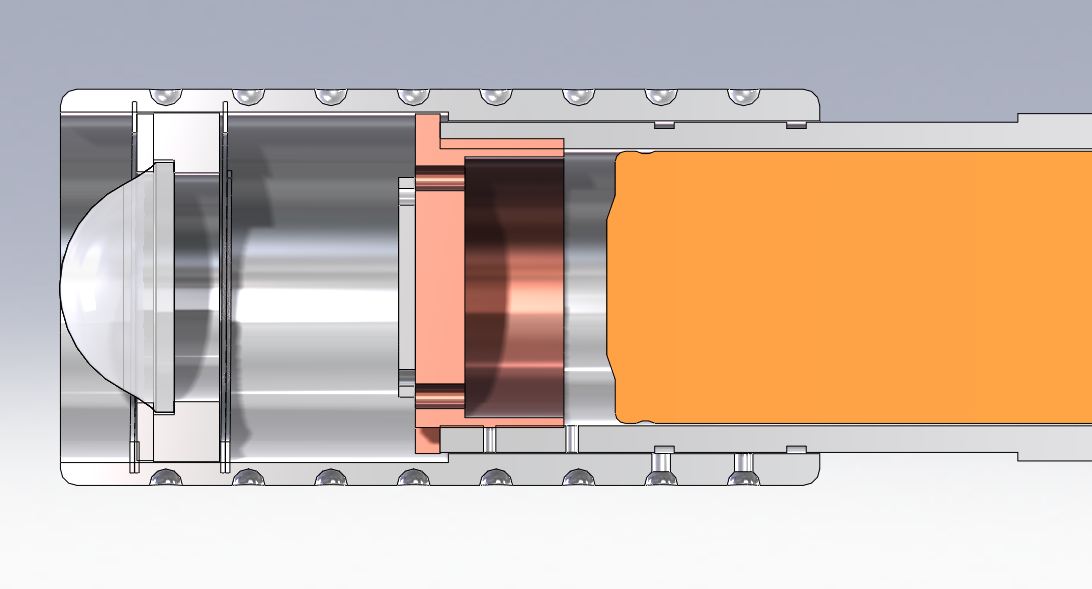

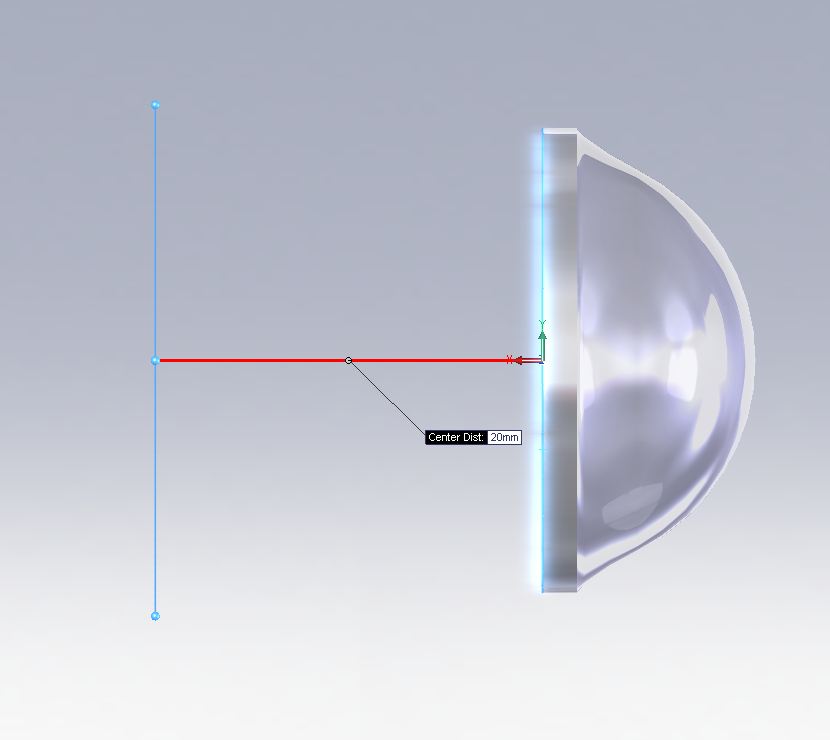

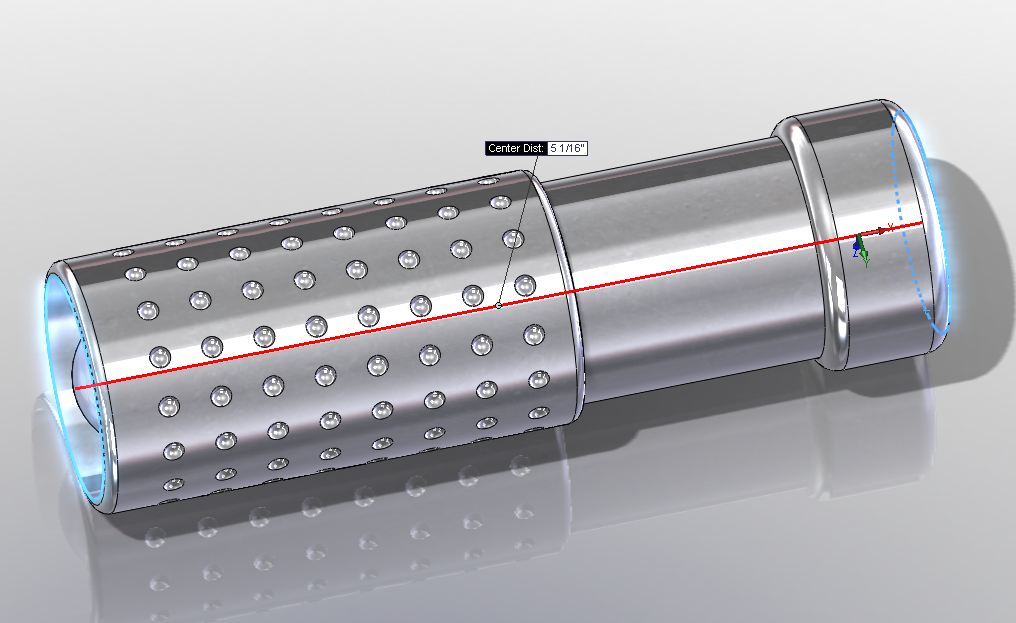

I am almost done with my custom Flood-to-throw design, but I need to find out what is permissible in this section of the forums.

I have a machinist that can do work for me, but I don't know if he can thread as well as the experts here. Dies and taps for the 1+ inch diameters are stupidly expensive, and I can't justify them for a one-off flashlight.

So, if I share my design with pictures and what not, can I ask for bidders to help out with the threading portion alone? Or, would this get turned down because they would want to make the entire flashlight?

The reason I ask is that my machinist is local, and virtually family. I really want to be there as he machines so that we can test-fit and tweek slowly, and be creative together. However, I can visualize the nearly-completed flashlight getting ruined once the threading begins.

Some advice would be very helpful.

Some info: The design is in Solidworks, which I use every day. I would be able to supply dimensioned prints with a bill of material to whatever degree is required.

If this thread drums up some interest, I'll throw some screen caps in here. Or... perhaps screen caps need to be first. LOL..... I guess I'll learn.

Thanks!

MG lovecpf

I have a machinist that can do work for me, but I don't know if he can thread as well as the experts here. Dies and taps for the 1+ inch diameters are stupidly expensive, and I can't justify them for a one-off flashlight.

So, if I share my design with pictures and what not, can I ask for bidders to help out with the threading portion alone? Or, would this get turned down because they would want to make the entire flashlight?

The reason I ask is that my machinist is local, and virtually family. I really want to be there as he machines so that we can test-fit and tweek slowly, and be creative together. However, I can visualize the nearly-completed flashlight getting ruined once the threading begins.

Some advice would be very helpful.

Some info: The design is in Solidworks, which I use every day. I would be able to supply dimensioned prints with a bill of material to whatever degree is required.

If this thread drums up some interest, I'll throw some screen caps in here. Or... perhaps screen caps need to be first. LOL..... I guess I'll learn.

Thanks!

MG lovecpf