Hi all,

Need some expert advice!

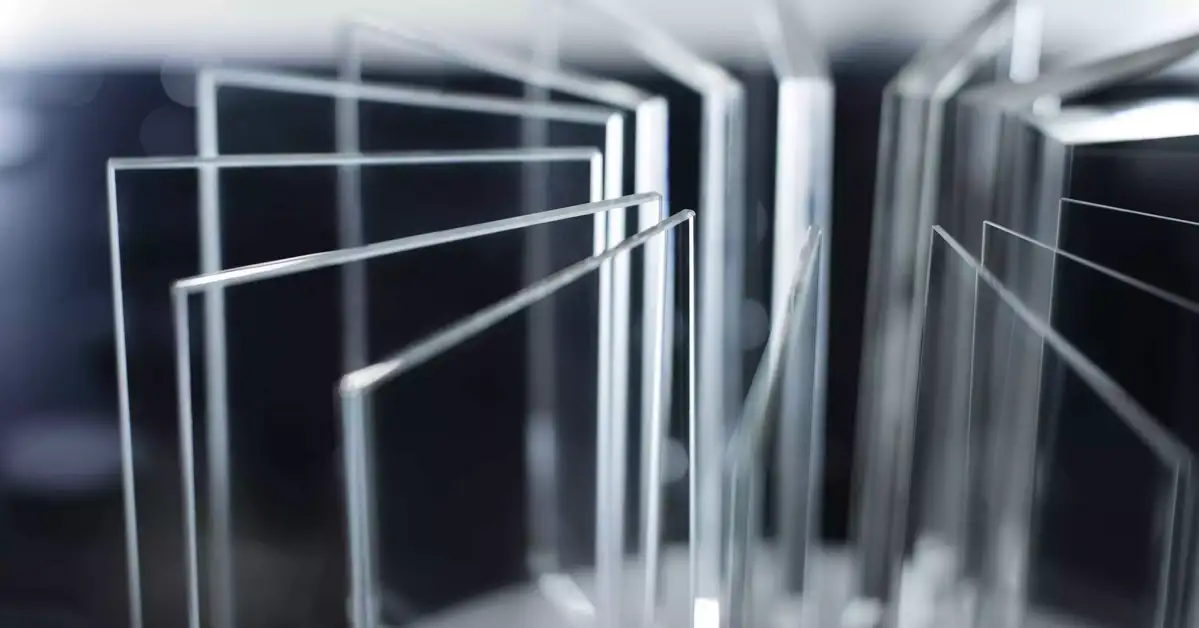

I require a flat piece of glass about 1mm thick and roughly 70mm x 35mm in size for use in a bicycle light. My primary concern is transparency followed closely by scratch resistance, but also some glass cost is far too expensive. I'm hoping I can find the optimal solution. One concern is if the glass is custom made then there's a larger risk of impurities or lack of correct polishing.

The light hits the glass mostly square on which (I believe) means reflectivity is less of a concern then opaqueness.

For example in quantities of 1,000 I've been quoted $9.80/each for sapphire and $1.42 for 'tempered glass', which I guess is soda-lime. From what I read borosilicate is much more scratch resistant than soda-lime, but I can't find any borosilicate vs tempered data.

Be good to know what is the price-transparency-scratch-resistance optimal glass!

Cheers!

Andrew

Need some expert advice!

I require a flat piece of glass about 1mm thick and roughly 70mm x 35mm in size for use in a bicycle light. My primary concern is transparency followed closely by scratch resistance, but also some glass cost is far too expensive. I'm hoping I can find the optimal solution. One concern is if the glass is custom made then there's a larger risk of impurities or lack of correct polishing.

The light hits the glass mostly square on which (I believe) means reflectivity is less of a concern then opaqueness.

For example in quantities of 1,000 I've been quoted $9.80/each for sapphire and $1.42 for 'tempered glass', which I guess is soda-lime. From what I read borosilicate is much more scratch resistant than soda-lime, but I can't find any borosilicate vs tempered data.

Be good to know what is the price-transparency-scratch-resistance optimal glass!

Cheers!

Andrew