Gunner12

Flashaholic

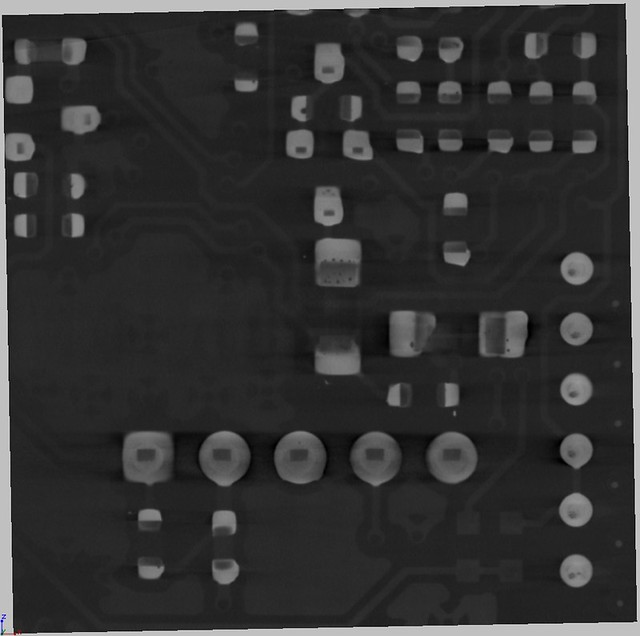

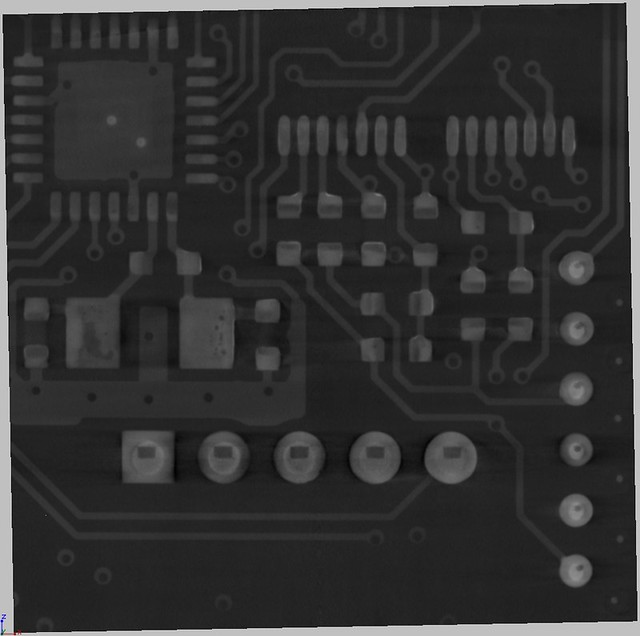

Came across this video about LED failures from Creative Electron:

https://youtu.be/UoxexFBmr0E?t=3m48s

Didn't know about solder voids, now I know that solder can sometimes look like a sponge.

So, if your build isn't getting as bright as you expect, or is dying early, blame the voids!

https://youtu.be/UoxexFBmr0E?t=3m48s

Didn't know about solder voids, now I know that solder can sometimes look like a sponge.

So, if your build isn't getting as bright as you expect, or is dying early, blame the voids!