StrayLight

Enlightened

WITHDRAWN

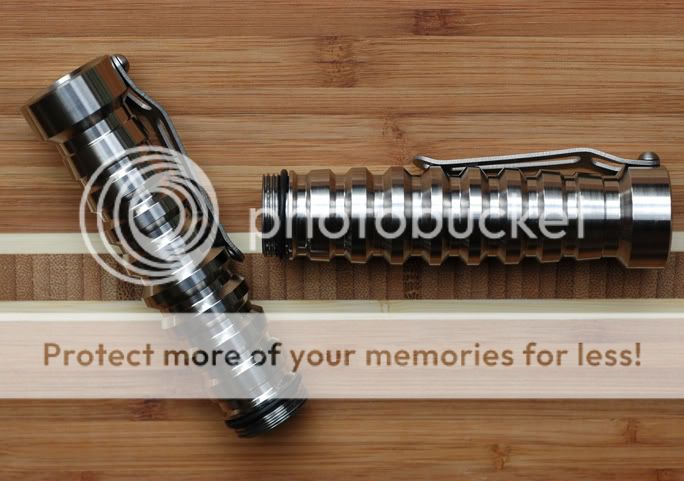

I would like to have my McGizmo Cx2 titanium body bored slightly to accommodate AW protected 17670 rechargeable cells. I have four cells and, because of the variations in thickness/placement of the protection circuit and shrinkwrap, only one fits (and snugly). I think less than 1/16" total material removed would be necessary.

Anyone interested in taking on this project needs to have a track record here at CPF for doing this kind of precision work in titanium. I'm not about to pay someone to have a go at my $$$ McGizmo with their Dremel or drill press because they feel "up to the challenge". Thanks for understanding.

Thanks for looking.

I would like to have my McGizmo Cx2 titanium body bored slightly to accommodate AW protected 17670 rechargeable cells. I have four cells and, because of the variations in thickness/placement of the protection circuit and shrinkwrap, only one fits (and snugly). I think less than 1/16" total material removed would be necessary.

Anyone interested in taking on this project needs to have a track record here at CPF for doing this kind of precision work in titanium. I'm not about to pay someone to have a go at my $$$ McGizmo with their Dremel or drill press because they feel "up to the challenge". Thanks for understanding.

Thanks for looking.

Last edited: