ahorton

Enlightened

- Joined

- Jul 22, 2008

- Messages

- 715

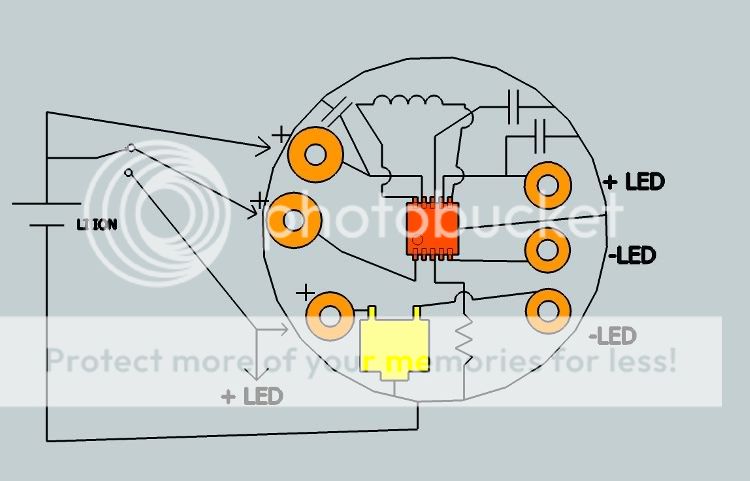

I have searched but not found. I'd love to know why this type of LED driver does not seem to exist:

3.0V-4.2V input voltage (1 Li Ion or similar)

The driver would be based around some sort of sensor that knows if the input voltage is more or less than 3.6V (or similar).

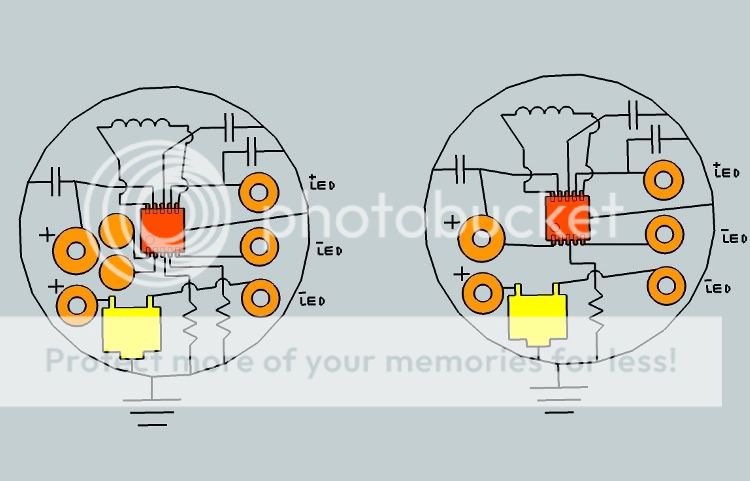

* When the input voltage is more than 3.6V, the LED current is limited via resistor or linear regulator (eg, AMC7135).

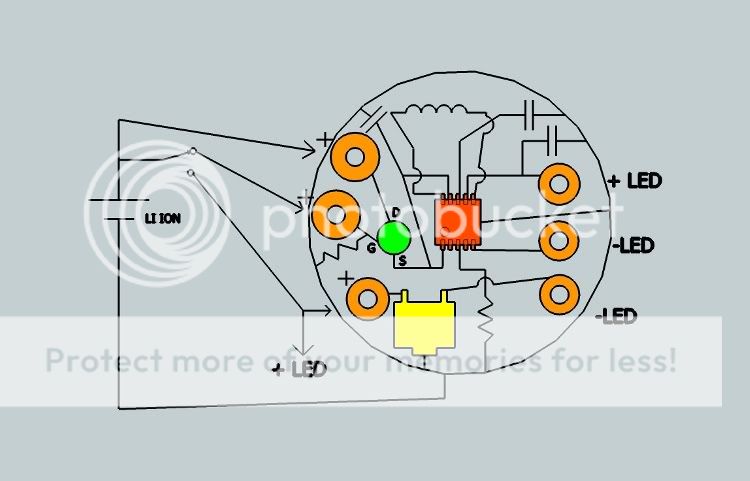

* When the input voltage is less than 3.6V, the LED is powered directly from the input (direct drive, probably through a Mosfet).

I have used AMC7135 drivers before but never like the way they have a 0.1V drop across the regulator once they fall out of regulation.

Also, can anyone point me towards some Mosfets (and other transistors) that operate well (turn on strong) at 3V? I have only used 5V ones in the past and do not think they would work well with voltage range of a single Li Ion cell.

3.0V-4.2V input voltage (1 Li Ion or similar)

The driver would be based around some sort of sensor that knows if the input voltage is more or less than 3.6V (or similar).

* When the input voltage is more than 3.6V, the LED current is limited via resistor or linear regulator (eg, AMC7135).

* When the input voltage is less than 3.6V, the LED is powered directly from the input (direct drive, probably through a Mosfet).

I have used AMC7135 drivers before but never like the way they have a 0.1V drop across the regulator once they fall out of regulation.

Also, can anyone point me towards some Mosfets (and other transistors) that operate well (turn on strong) at 3V? I have only used 5V ones in the past and do not think they would work well with voltage range of a single Li Ion cell.

Last edited:

I understand if nobody ever wants to take me seriously ever again.

I understand if nobody ever wants to take me seriously ever again.