capcouillon

Newly Enlightened

- Joined

- Sep 26, 2013

- Messages

- 3

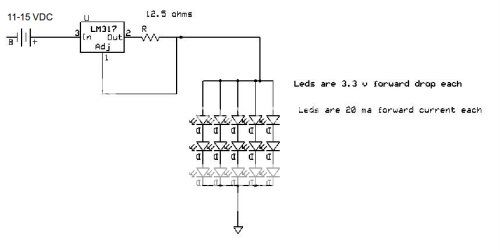

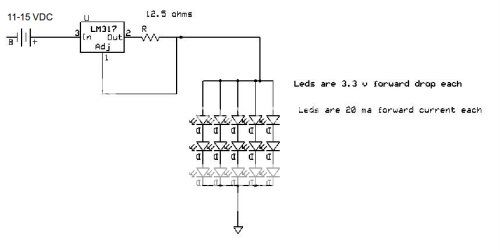

Have a project I want to pursue that requires some leds. Technically secure in the realm of hardware that requires taps and dies, but over my head when it comes to hardware that requires ic's and cazapitors... I can (more or less) read a schematic and stick the wires together, but the more esoteric aspects ususally evade me. As to the whys of this project, I will post more info if and when I manage to get a working prototype. Below I have posted the basic project parameters as well as a current control circuit I plan to use for ver 0.01. If y'all could do a quick skim and let me know of any glaring errors, or obvious revisions before the first build, it would be much appreciated. If all goes well, hope to build several hundred of these little dudes.

Power Supply: 11-15 VDC

Current Control IC Texas Inst LM317

Temperature Range: 0 - 50 degree C

Heat Dissipation: Very low, all electronics to be potted inside plastic container.

LED Type: Cree 503D-WAN (or similar) Vf= 3.2V Current= 20mA Millicandela Rating= 28150

Total LED: 15 in 3(s) x 5(p) array

Critical Factors: Cost and Reliability. Materials cost (LED+Control Components) vs Assembly time . Size of assembled control circuits.

TIA for your input and suggestions

Cap' Couillon

Power Supply: 11-15 VDC

Current Control IC Texas Inst LM317

Temperature Range: 0 - 50 degree C

Heat Dissipation: Very low, all electronics to be potted inside plastic container.

LED Type: Cree 503D-WAN (or similar) Vf= 3.2V Current= 20mA Millicandela Rating= 28150

Total LED: 15 in 3(s) x 5(p) array

Critical Factors: Cost and Reliability. Materials cost (LED+Control Components) vs Assembly time . Size of assembled control circuits.

TIA for your input and suggestions

Cap' Couillon

Last edited: