PlanBTorches

Newly Enlightened

Hi All,

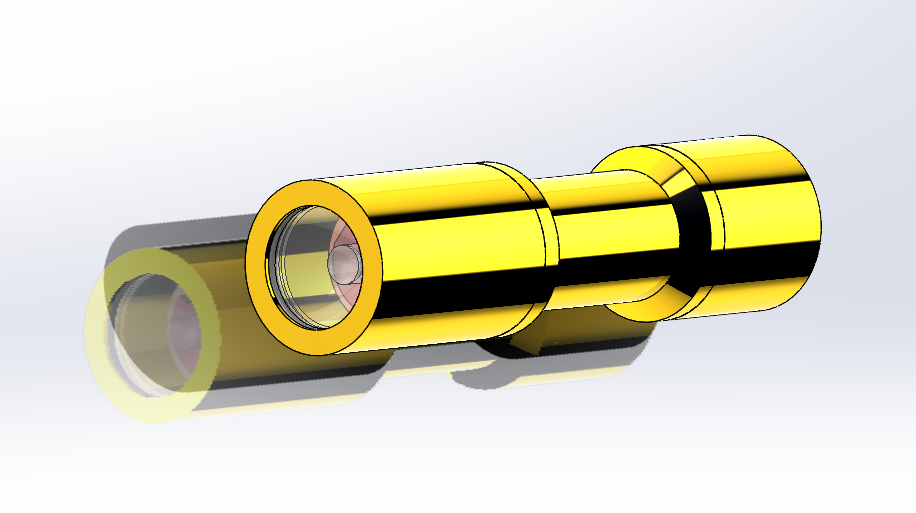

I'm starting my first flashlight build and I thought it might be fun to document the process here for the entertainment value and (if any kind soles wander by) the feedback. To kick things off I'm using store bought internals from mntelectronics (selected mostly at random) and sticking with a pretty standard three part design (see renders). To keep things easy the material is 360 brass, and I'm building without a pocket clip for this round (I've been struggling with how to handle the heat treat). My goal here is to build some design intuition and get some experience with the various machining operations involved. I do plan to learn more about LED selection and driver design, but that (along with the pocket clip) is for a future project.

Design Notes:

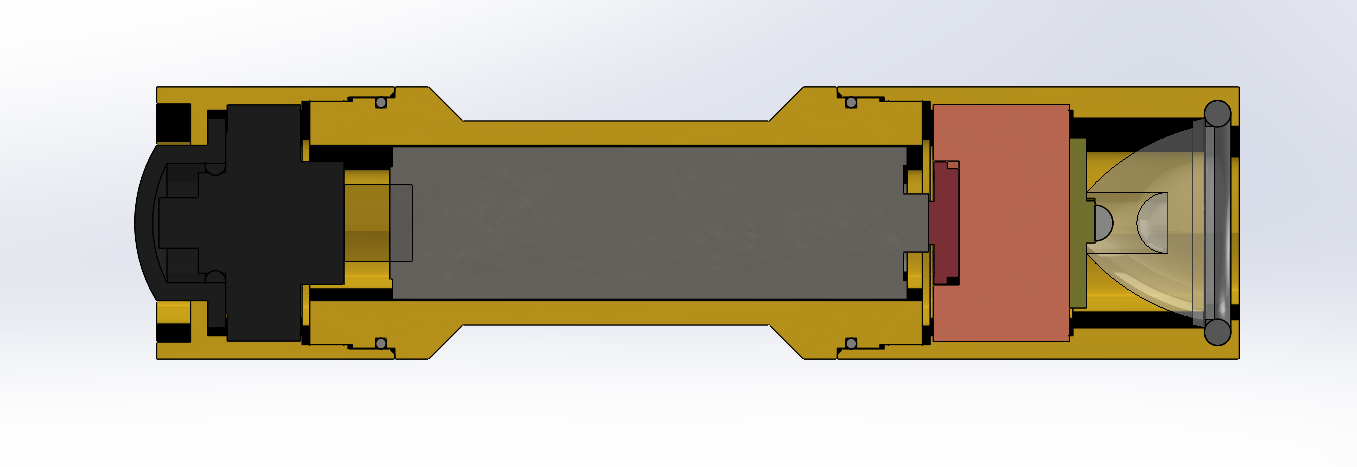

I plan to use a 0.9x40 thread for holding the three sections together, and the mcclickly thread for both the pill and switch. The pill will made of either copper or aluminum depending on whether I can find a not-totally-misserable-to-machine copper alloy to work with (thoughts appreciated!). The two barrell o-rings and one front o-ring are both set up for around 5 thou of compression when the light is closed up.

The Parts:

I am totally new to this, so I'd love any thoughts, feedback, opinions, or comments that come to mind! I'll post more updates as the project progresses.

I'm starting my first flashlight build and I thought it might be fun to document the process here for the entertainment value and (if any kind soles wander by) the feedback. To kick things off I'm using store bought internals from mntelectronics (selected mostly at random) and sticking with a pretty standard three part design (see renders). To keep things easy the material is 360 brass, and I'm building without a pocket clip for this round (I've been struggling with how to handle the heat treat). My goal here is to build some design intuition and get some experience with the various machining operations involved. I do plan to learn more about LED selection and driver design, but that (along with the pocket clip) is for a future project.

Design Notes:

I plan to use a 0.9x40 thread for holding the three sections together, and the mcclickly thread for both the pill and switch. The pill will made of either copper or aluminum depending on whether I can find a not-totally-misserable-to-machine copper alloy to work with (thoughts appreciated!). The two barrell o-rings and one front o-ring are both set up for around 5 thou of compression when the light is closed up.

The Parts:

- 45 degree TIR from Mountain Electronics.

- Nicha 316 LED board from Mountain Electronics.

- MISC AA driver board from mountain electronics.

- mcclickly tail switch.

- Various o-rings from mcmaster carr.

I am totally new to this, so I'd love any thoughts, feedback, opinions, or comments that come to mind! I'll post more updates as the project progresses.