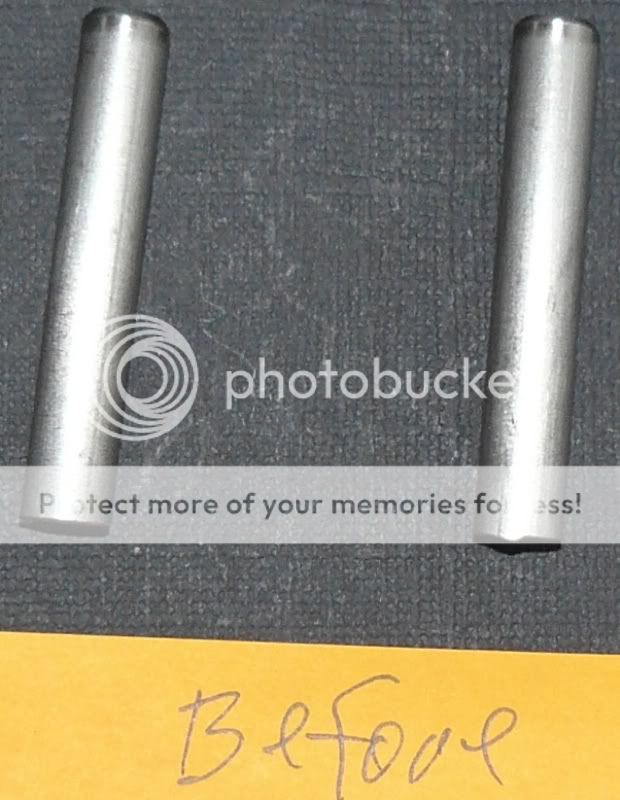

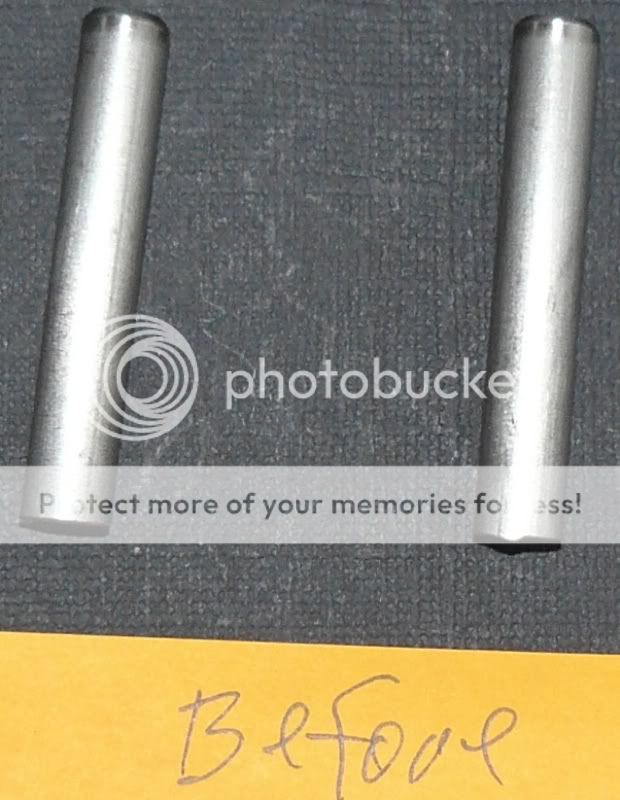

Experiment: Two raw pieces of Ti anodized in different baths @ 85VDC until amperage dropped to .10. I prepared the raw Ti in a lye bath, rinsed in well water, scrubbed with dish soap in a 3M surfaced sponge and then rinsed in warm well water (handling via stainless tweezers).

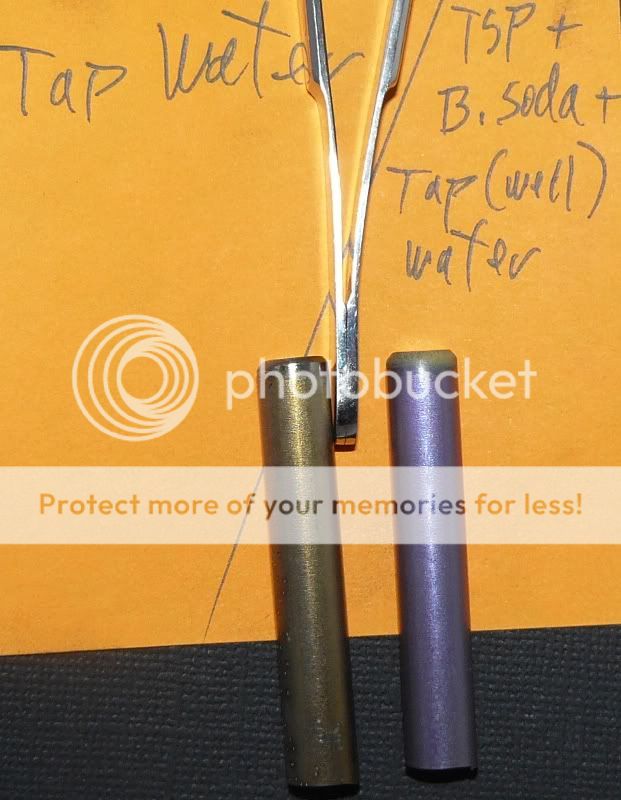

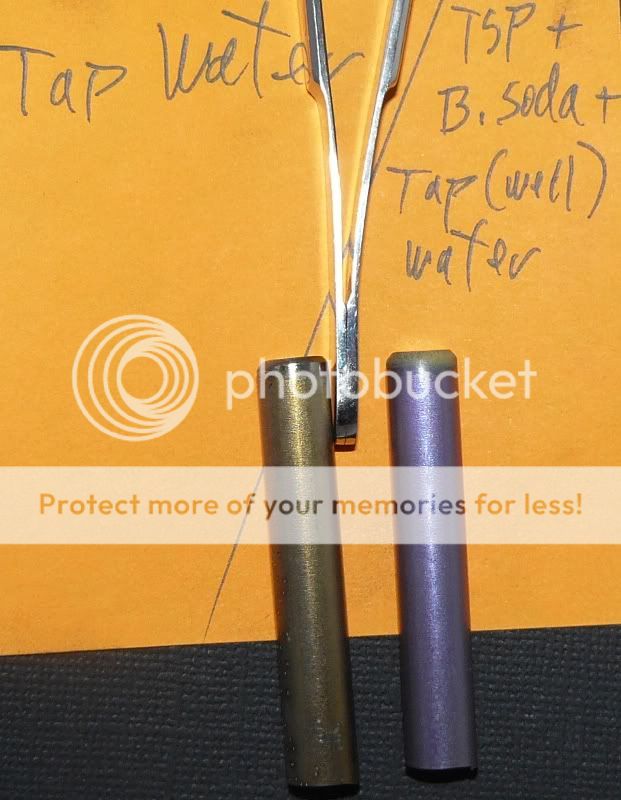

One bath: TSP, baking soda and well water.

Other bath: Well water.

I rinsed off the large Ti plate in the bath between baths but only dried off the Ti rod (connects to the target) on a towel between baths.

Result: The dirty bath quickly gave the purple anodization with lots of bubbles while the clean bath gave the gold/yellowish anodization very slowly with few bubbles. Clearly, the ingredients of the bath make a different.

Before:

After:

The setup:

oregon

One bath: TSP, baking soda and well water.

Other bath: Well water.

I rinsed off the large Ti plate in the bath between baths but only dried off the Ti rod (connects to the target) on a towel between baths.

Result: The dirty bath quickly gave the purple anodization with lots of bubbles while the clean bath gave the gold/yellowish anodization very slowly with few bubbles. Clearly, the ingredients of the bath make a different.

Before:

After:

The setup:

oregon