Bought 100 pieces of LEDs. 50 degrees. All LEDs have a hole in the beam, I'm not sure if this is normal, maybe it's some kind of defective batch. When I insert them into a Streamlight with 7 5 mm diodes, it does not matter, it turns out a beautiful flood beam. I'm wondering, if somehow grind the lens part of the LED, is it possible to get rid of this hole? I want to insert these diodes into 1 diode flashlights that go for gifts. Although those to whom I give them do not pay attention to the presence of holes at all and even to the color of the diode (if it were pure blue they would not have noticed), but my OCD does not give me peace.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hole in beam 5 mm LED

- Thread starter desert.snake

- Start date

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

Dave_H

Flashlight Enthusiast

First question is where the LEDs came from...brand, reliable source, and does it have part number and datasheet?

Spacial pattern should not normally have a "hole" at boresight, sounds like a defect or poor design. OTOH cheap zoomie flashlight I have when focused to narrow beam, projects image of the square LED die including bond wires.

How (and why) would you regrind lens on 5mm LEDs, unless you have proper equipment? Is it round, or parabolic?

Dave

Spacial pattern should not normally have a "hole" at boresight, sounds like a defect or poor design. OTOH cheap zoomie flashlight I have when focused to narrow beam, projects image of the square LED die including bond wires.

How (and why) would you regrind lens on 5mm LEDs, unless you have proper equipment? Is it round, or parabolic?

Dave

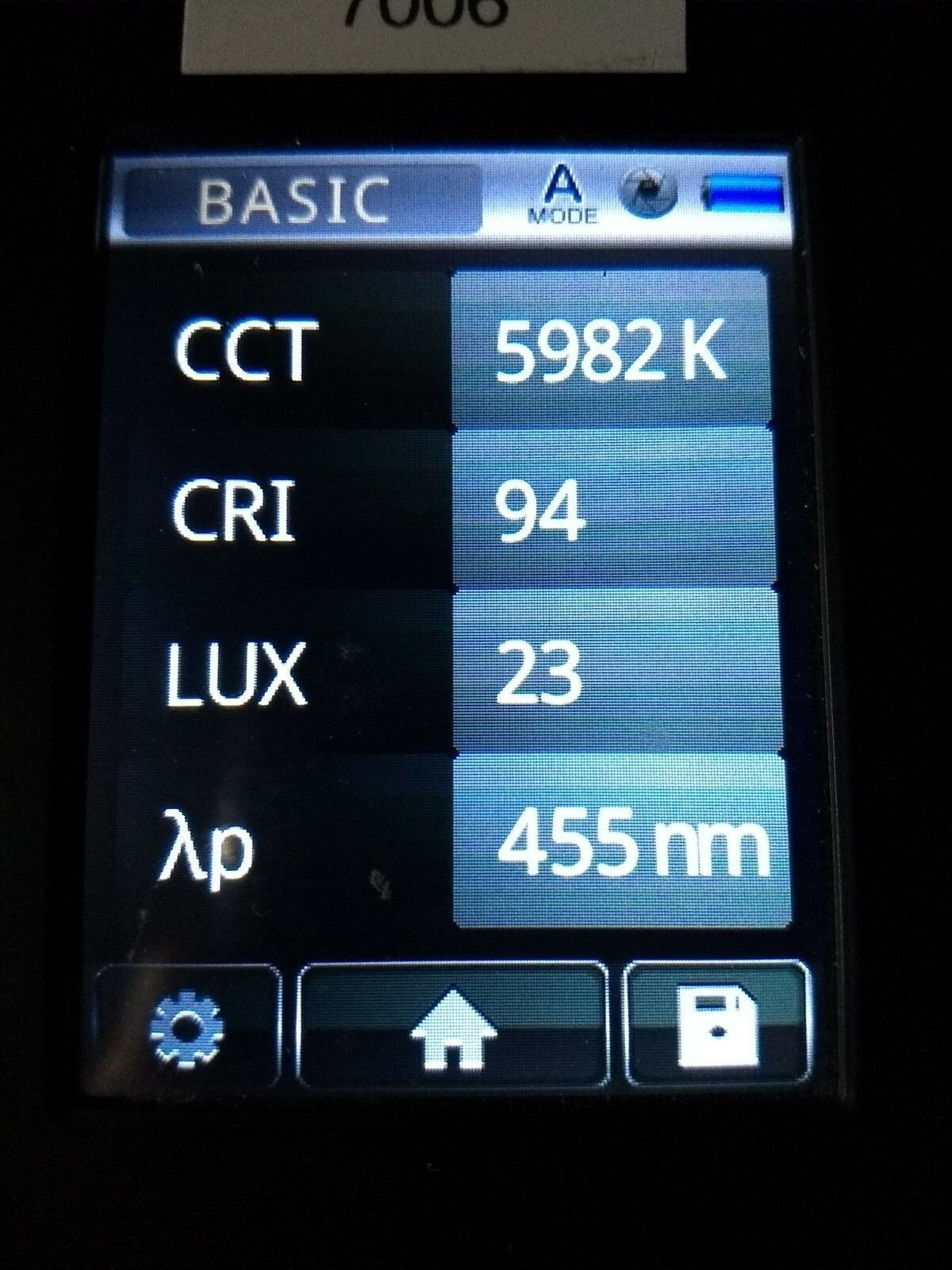

I looked more closely, the manufacturer is indicated by them - TogJia Optoelectronics Technology (China) Co., Ltd.

They have a website, but I did not find any diodes with high CRI

Grinding is not a problem with the sandpaper, it's quite soft plastic. I'm wondering if anyone had the same defects and how they treat theirs to remove them?

They have a website, but I did not find any diodes with high CRI

Grinding is not a problem with the sandpaper, it's quite soft plastic. I'm wondering if anyone had the same defects and how they treat theirs to remove them?

Dave_H

Flashlight Enthusiast

You would have to grind with some precision, or the pattern will not be uniform. Probably need to polish or at least use 400-grit waterproof paper. That my not solve the problem. Sounds like a lot of effort. Suggest using those LEDs for something which doesn't matter, and getting better ones.

BTW that webpage gets blocked, due to "malware" detected.

Dave

BTW that webpage gets blocked, due to "malware" detected.

Dave

No problems with webpage.

The solution is found, it is necessary to cut the dome at about 90 degrees and then sand all the smooth parts on top. This black stone is about 800 grit and about 2 minutes of work. The red tones of the tree conveys well. Photo next to Nichia DS 3mm.

The solution is found, it is necessary to cut the dome at about 90 degrees and then sand all the smooth parts on top. This black stone is about 800 grit and about 2 minutes of work. The red tones of the tree conveys well. Photo next to Nichia DS 3mm.

Attachments

Last edited:

I was going to suggest try chapstick on the dome to experiment how/where to sand but it looks like you've solved the issue.

It is kinda strange to see what looks like filament shadow from an LED.

I did not know my incan flashlights had a hole in the beam or filament shadow until CPF told me so. And blue tint? What's that? Then CPF showed me the err of my ways……thousands of dollars later. 😂

It is kinda strange to see what looks like filament shadow from an LED.

I did not know my incan flashlights had a hole in the beam or filament shadow until CPF told me so. And blue tint? What's that? Then CPF showed me the err of my ways……thousands of dollars later. 😂

Yes, sometimes it's better not to go deep into the topic and use what is))

DIWdiver

Flashlight Enthusiast

Larger LEDs typically don't have bond wires crossing over the top of the die. But I've never seen a 5mm LED that didn't have a bond wire right in the middle of the top of the die. It's not hard to see if you have good eyes or good magnification.

In a fairly narrow beam LED, the bond point and sometimes even the bond wire will create a visible shadow in the beam, because the 'lens' of the LED creates a reasonable image of the die.

If you diffuse the beam, any shadows get diffused too, so they are no longer visible.

The modifications you made to the LEDs changed the narrow beam to a diffuse one. If you want a wide beam, this is a very reasonable thing to do. It solved your problem and you should be perfectly happy, as well as proud of yourself for figuring out a good solution to your problem.

If you wanted a very narrow beam, or a throwy light, this would be a very bad thing to do. The only solution in this case would be a different LED or several LEDs to make the bright and dark spots blend together and be less visible.

In a fairly narrow beam LED, the bond point and sometimes even the bond wire will create a visible shadow in the beam, because the 'lens' of the LED creates a reasonable image of the die.

If you diffuse the beam, any shadows get diffused too, so they are no longer visible.

The modifications you made to the LEDs changed the narrow beam to a diffuse one. If you want a wide beam, this is a very reasonable thing to do. It solved your problem and you should be perfectly happy, as well as proud of yourself for figuring out a good solution to your problem.

If you wanted a very narrow beam, or a throwy light, this would be a very bad thing to do. The only solution in this case would be a different LED or several LEDs to make the bright and dark spots blend together and be less visible.

Yes, you are completely right. True, I also have an idea that the crystal is not at the optimal distance in relation to the lens, that is, when this batch was poured, they made a mistake with the immersion value. Like a Maglite has a hole in the beam when the reflector isn't up enough.

The diodes themselves should have an angle of 50 degrees, this is already a fluder, if you compare it side by side, then the modified one seems to have a beam not much wider.

The diodes themselves should have an angle of 50 degrees, this is already a fluder, if you compare it side by side, then the modified one seems to have a beam not much wider.

alpg88

Flashlight Enthusiast

- Joined

- Apr 19, 2005

- Messages

- 5,342

to me it looks like bad batch or just crappy leds, i started moding lights 15+ years ago, there was nothing but 5 and 10mm leds, even back than i have not seen such spots

Dave_H

Flashlight Enthusiast

I didn't think grinding the top flat would work but if it does for this case that is good.

Many cheap 5mm or 3mm LEDs don't project a great uniform beam, usually see bright spot with ringed edges on some of the narrower ones.

I once ground the top of a 5mm LED flat but then proceeded to drill a small hole towards the die (but not hitting it), then inserted a plastic fiber and glued in place, a sort of integrated light pipe. Seemed to work and was just for fun.

Dave

Many cheap 5mm or 3mm LEDs don't project a great uniform beam, usually see bright spot with ringed edges on some of the narrower ones.

I once ground the top of a 5mm LED flat but then proceeded to drill a small hole towards the die (but not hitting it), then inserted a plastic fiber and glued in place, a sort of integrated light pipe. Seemed to work and was just for fun.

Dave

Last edited: