You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Surefire boring service

- Thread starter precisionworks

- Start date

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

- Status

- Not open for further replies.

precisionworks

Flashaholic

I haven't handled an E2 in some time, but the external appearance of the tube looks like it should work (for securing in the lathe). Pretty sure I'll have to bore a custom set of soft jaws for that size tube, but that's not a big deal ... my soft jaw collection is growing :laughing:doing E2 bodies to 17670?

Are you saying that only the first 20mm of the tube, on the switch end, needs to be enlarged? That can certainly be done. If you don't mind sending the complete light (plus the 17670's that you plan to use) that would be best ... I can measure, bore/ream/hone, and verify operation of the light. Same pricing as a 6P, $40 plus return shipping.They should only need 20mm in the tail end bored.

Chrisdm

Enlightened

- Joined

- Mar 10, 2011

- Messages

- 917

And returning your M2 in the mail this afternoon :thumbsup:

My shop will be closed for the holiday (5/27 - 5/30) & I wanted to get the M2 back to Chris without the holiday delay. A few "after" photos ...

Thanks Barry, great job and super fast service!! When I threw that Redilast battery in there it was honestly wishful thinking on my part. I have a couple other bored Surefires from various modders and these fat Redilast cells usually don't fit well. But you made it fit perfectly, thanks again!

precisionworks

Flashaholic

Euroken sent a message asking if I would "provide a boring service for non SF host ...and, second, whether you would bore a three piece body." The answers to those questions are YES and YES

I was initially concerned about maintaining adequate wall thickness, but measurements showed that the body could be bored/reamed/honed while still leaving good wall thickness. It took a little while to figure out the fixturing on the lathe, but nothing insurmountable.

They measure quite a bit larger in diameter than my "standard" AW18650. The AW cells end up with about .010" radial clearance, while the RediLast cells have just .005" (about the thickness of a business card). .005" is plenty of room, as there is .005" all the way around the cell. Happy to hear that you are pleased

I was initially concerned about maintaining adequate wall thickness, but measurements showed that the body could be bored/reamed/honed while still leaving good wall thickness. It took a little while to figure out the fixturing on the lathe, but nothing insurmountable.

+1these fat Redilast cells usually don't fit well.

They measure quite a bit larger in diameter than my "standard" AW18650. The AW cells end up with about .010" radial clearance, while the RediLast cells have just .005" (about the thickness of a business card). .005" is plenty of room, as there is .005" all the way around the cell. Happy to hear that you are pleased

Last edited:

euroken

Flashlight Enthusiast

Ohhh....that looks fantastic! Can't wait!

Pm sent regarding international shipping! I'm in NYC

Pm sent regarding international shipping! I'm in NYC

precisionworks

Flashaholic

LOL, that means you are NOT the member from LondonPm sent regarding international shipping! I'm in NYC

That tube is nicely made and all the threaded joints fit together very well. You'll have fun with it, whether you use it as a 6P or a 9P.

PM replied to.

Yeah, the tail threads are small (CR123 won't fit through, about the same diameter as the threads), the batteries go through the head end. A 17670 fits 90% of the way but the body narrows near the tail threads. You will have to bore from the head end.I haven't handled an E2 in some time, but the external appearance of the tube looks like it should work (for securing in the lathe). Pretty sure I'll have to bore a custom set of soft jaws for that size tube, but that's not a big deal ... my soft jaw collection is growing :laughing:

Are you saying that only the first 20mm of the tube, on the switch end, needs to be enlarged? That can certainly be done. If you don't mind sending the complete light (plus the 17670's that you plan to use) that would be best ... I can measure, bore/ream/hone, and verify operation of the light. Same pricing as a 6P, $40 plus return shipping.

Cheers,

Nova

precisionworks

Flashaholic

Nova, that shouldn't present any problems. My first concern on boring any light is to leave adequate thickness, especially at the O-ring groove (normally the thinnest part of any flashlight tube). Surefires have a (relatively) thick wall to begin with, and I use the minimum bore & ream diameter dimension that allows the battery to fit with just a bit of clearance.You will have to bore from the head end.

If you want to ship your light, I'll be happy to examine it & determine if it can be bored (which I believe it can). If for any reason it cannot be bored, I'll pay the return shipping to Australia. The fastest way to contact me is an email to precisionworks AT frontier DOT com.

PoliceScannerMan

Flashaholic

Got my 3P body back today, not bad, one week from shipment to receipt, with a holiday to boot.

Very clean work, no evidence the body was ever toouched, and the bored tube is super smooth, with a nice lip to hold the battery and make contact with the drop in.

Thanks Barry!

Very clean work, no evidence the body was ever toouched, and the bored tube is super smooth, with a nice lip to hold the battery and make contact with the drop in.

Thanks Barry!

euroken

Flashlight Enthusiast

Got my 3P body back today, not bad, one week from shipment to receipt, with a holiday to boot.

Very clean work, no evidence the body was ever toouched, and the bored tube is super smooth, with a nice lip to hold the battery and make contact with the drop in.

Thanks Barry!

Got mine yesterday.

Very well done, with buttery smooth bore. No sign of any anno missing on the body as PSM mentioned. The bore fits all my 18650 batteries, even the ones that are slightly largeand would jam in my other bored hosts.

In addition, talk about communication and prompt responses! Great experience as a whole.

Look forward to possible e series bores!

Cheers!

precisionworks

Flashaholic

Glad you like your light, Ken

Funny, as that's next on the list. I'm boring up a set of soft jaws to fit the E-series outside diameter, which is much smaller than any other Surefire I've handled. As you already know, the tail section is very small, so boring is done from the front (LE) end. Minimum wall thickness (at the forward O-ring groove) is very small, just barely enough for an 18mm cell, but it can be done. Boring for a 17mm cell leaves a much thicker and sturdier tube.Look forward to possible e series bores!

Last edited:

precisionworks

Flashaholic

The Surefire 6PX-Pro just arrived ... sweet light that has one of the nicest beams I've ever seen from SF.

Got out the micrometers & the bore gage to verify dimensions & found that all thickness readings are identical to the 6P (not a big surprise). Tried to unscrew the head only to find that it is bonded on tightly to the tube

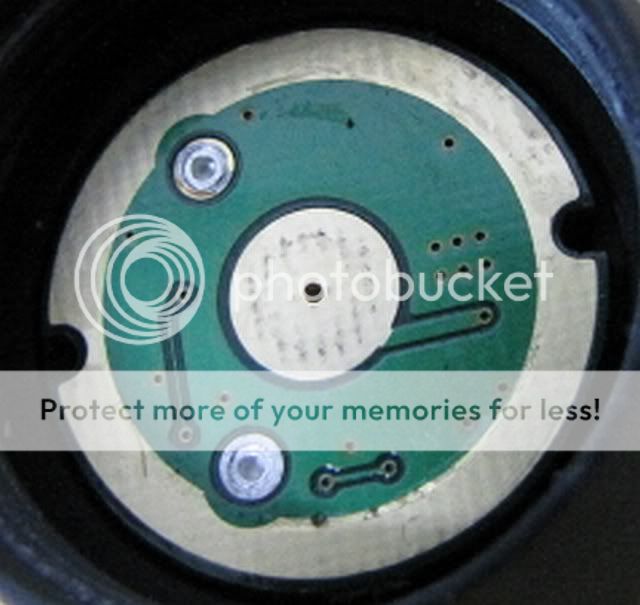

I remembered reading an article here on how one member had bored his 6PX, and noticed this photo:

Pretty easy to see the red Loctite adhesive that bonds the head to the tube. Red Loctite does soften above 325°F, but that sounded like a bad idea considering that the MPCB, emitter, reflector, etc., would all be subjected to this very high temp.

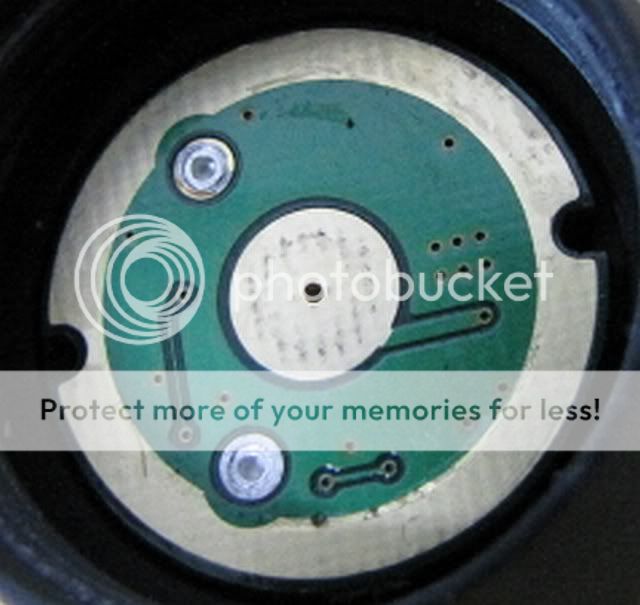

Even if the head had unscrewed easily there's another issue. The back of the MPCB uses no spring contact, but is dead flat:

Not a problem when using primaries, as primary cells have a positive contact post that sticks up far above the battery body (probably 3mm to 4mm). Many rechargeable cells are flat topped, like the AW cells I use, and a flat topped cell probably will make either poor contact or no contact with the MPCB. I thought about machining up a delrin ring with a copper post in the middle, to act as a positive contact extender, but that will have to wait until my business slows down.

If you have a 6PX and want it bored, there are probably people on CPF that will do it for you. At this time I don't plan to accept any for boring

Got out the micrometers & the bore gage to verify dimensions & found that all thickness readings are identical to the 6P (not a big surprise). Tried to unscrew the head only to find that it is bonded on tightly to the tube

I remembered reading an article here on how one member had bored his 6PX, and noticed this photo:

Pretty easy to see the red Loctite adhesive that bonds the head to the tube. Red Loctite does soften above 325°F, but that sounded like a bad idea considering that the MPCB, emitter, reflector, etc., would all be subjected to this very high temp.

Even if the head had unscrewed easily there's another issue. The back of the MPCB uses no spring contact, but is dead flat:

Not a problem when using primaries, as primary cells have a positive contact post that sticks up far above the battery body (probably 3mm to 4mm). Many rechargeable cells are flat topped, like the AW cells I use, and a flat topped cell probably will make either poor contact or no contact with the MPCB. I thought about machining up a delrin ring with a copper post in the middle, to act as a positive contact extender, but that will have to wait until my business slows down.

If you have a 6PX and want it bored, there are probably people on CPF that will do it for you. At this time I don't plan to accept any for boring

beach honda

Enlightened

Hey Barry,

Can you bore my C2 Centurion to accept 18650?

Thanks!

-Chris

Can you bore my C2 Centurion to accept 18650?

Thanks!

-Chris

precisionworks

Flashaholic

Chris,

I'm pretty sure the C2 will be almost identical to the M2 that was done for Chrisdm (see post #16). If for some reason it cannot be bored, I'll pay return shipping back to you.

This is a great time to send your light in, as I can usually bore it & return it within one business day. My "regular" job at the tool & die shop should pick up soon, but I'll continue to get lights finished ASAP.

I'll PM with shipping info.

I'm pretty sure the C2 will be almost identical to the M2 that was done for Chrisdm (see post #16). If for some reason it cannot be bored, I'll pay return shipping back to you.

This is a great time to send your light in, as I can usually bore it & return it within one business day. My "regular" job at the tool & die shop should pick up soon, but I'll continue to get lights finished ASAP.

I'll PM with shipping info.

precisionworks

Flashaholic

That light is about to be an international traveler :laughing:I would like to post you my E2E

Nova, if you can find the 6P and send it along at the same time, shipping for two lights should cost the same as sending just one. I have a personal E2L to bore, a friend in town also wants his E2L bored, and I plan on boring your E2E at the same time.

PM sent with details ...

beach honda

Enlightened

Brother Barry,

The light is being shipped to you directly from shao.fu.tzer. Paypal has been sent as well.

Thanks very much!

-Chris

The light is being shipped to you directly from shao.fu.tzer. Paypal has been sent as well.

Thanks very much!

-Chris

precisionworks

Flashaholic

I measured a couple of E2L tubes tonight, and those measurements are not what I thought they would be

In post #31, I stated " Minimum wall thickness (at the forward O-ring groove) is the same as a 6P..." it is not. In fact, the O-ring groove is .025" smaller than on the 6P. That does still leave an option. As Nova mentioned in post #27 " A 17670 fits 90% of the way but the body narrows near the tail threads. You will have to bore from the head end." I didn't have time to run a bore gage down the tube tonight, but will verify those dimensions tomorrow. The tube can be bored to as much as 17.2mm (.680") to accept the 17670 while still leaving adequate thickness at the O-ring groove.

IMO, a 17670 is the best & most practical option for the E-series lights. Boring for the 18650 can be done, but the walls will be left really thin (about .011"-.012"). There are commercial tubes having that same wall thickness, so it's probably adequate. The battery fit will be almost snug with an AW protected cell, and a RediLast cell will not even enter the tube. Depending on the individual cells you use, the labels may have to be removed ... it's that close.

In post #31, I stated " Minimum wall thickness (at the forward O-ring groove) is the same as a 6P..." it is not. In fact, the O-ring groove is .025" smaller than on the 6P. That does still leave an option. As Nova mentioned in post #27 " A 17670 fits 90% of the way but the body narrows near the tail threads. You will have to bore from the head end." I didn't have time to run a bore gage down the tube tonight, but will verify those dimensions tomorrow. The tube can be bored to as much as 17.2mm (.680") to accept the 17670 while still leaving adequate thickness at the O-ring groove.

IMO, a 17670 is the best & most practical option for the E-series lights. Boring for the 18650 can be done, but the walls will be left really thin (about .011"-.012"). There are commercial tubes having that same wall thickness, so it's probably adequate. The battery fit will be almost snug with an AW protected cell, and a RediLast cell will not even enter the tube. Depending on the individual cells you use, the labels may have to be removed ... it's that close.

Last edited:

Fusion_m8

Flashlight Enthusiast

Barry:

PM sent.

PM sent.

precisionworks

Flashaholic

Fusion m8,

PM replied to. My wife & I got a good laugh out of your sig line She & I have been married (almost) as long as Surefire has been making lights.

She & I have been married (almost) as long as Surefire has been making lights.

PM replied to. My wife & I got a good laugh out of your sig line

- Status

- Not open for further replies.

Similar threads

Latest posts

-

Is the 796 bulb a safe application for a reverse light?

- Latest: Hamilton Felix

-

-

-

-

-