sylathnie

Enlightened

- Joined

- Jan 19, 2008

- Messages

- 250

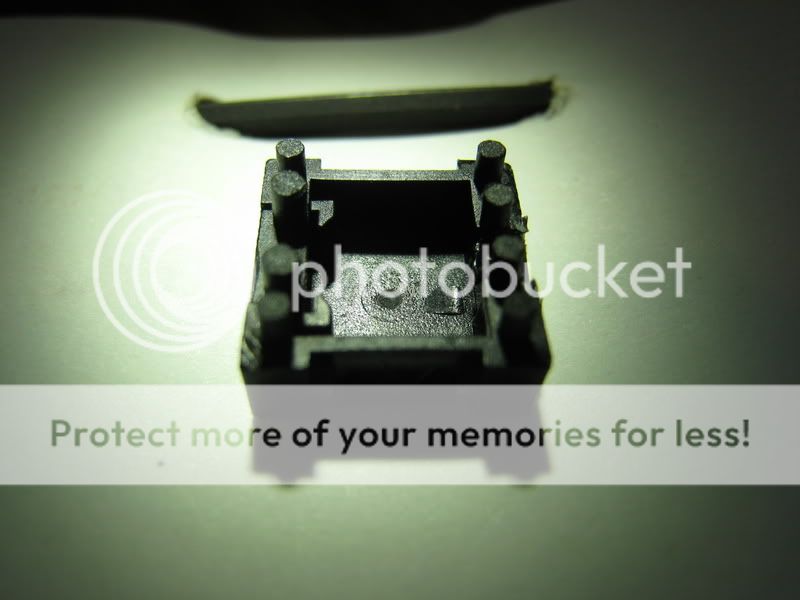

Recently a TK-11 I gave as a gift suffered a failed switch. Sometimes it would turn on and sometimes it would take multiple clicks. 4Sevens immediately took care of the issue and very quickly sent me a replacement. I took the opportunity to take apart the old failed switch. Here are a few pictures of what I found.

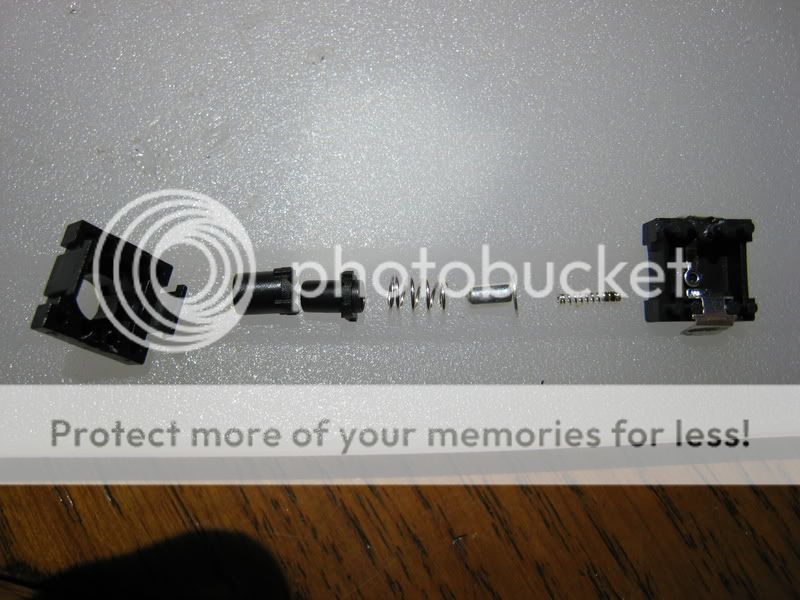

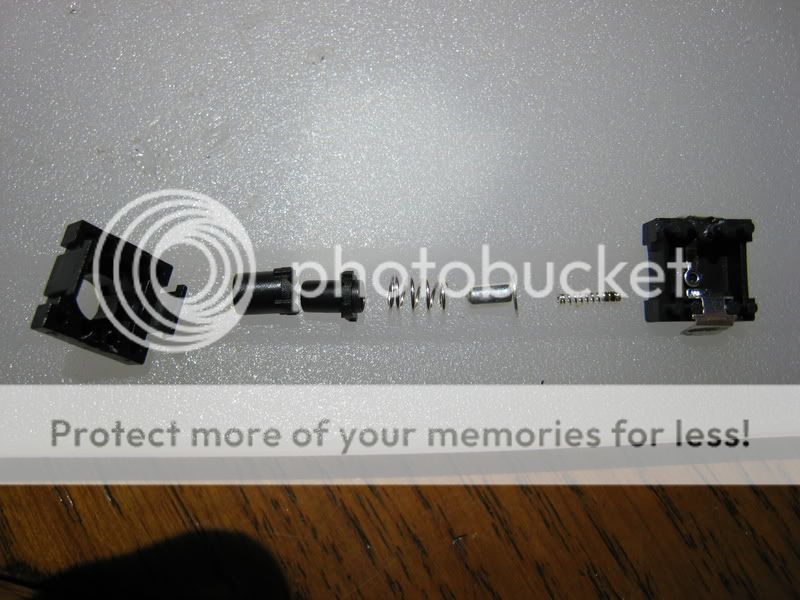

As you can see there is a tiny pin (black) that holds the small spring in the center of the base of the switch. This pin has broken off and lodged within the center of the small spring. Once the pin is broken off the contact ring is free to move from side to side and therefore not make contact with the proper pieces.

I can see no easy solution to this weakness. I've save all the pieces and may try to re-assemble it. Maybe as momentary only.

As you can see there is a tiny pin (black) that holds the small spring in the center of the base of the switch. This pin has broken off and lodged within the center of the small spring. Once the pin is broken off the contact ring is free to move from side to side and therefore not make contact with the proper pieces.

I can see no easy solution to this weakness. I've save all the pieces and may try to re-assemble it. Maybe as momentary only.