wquiles

Flashaholic

The PhD-M6 battery pack is a custom pack for the Sure Fire M6, and it is composed of a custom battery pack designed and built by Eric (mdocod), and a custom PWB/driver and firmware done by me. Eric recently finished a great post showing how he creates the PhD-M6 custom battery pack, and this post shows what happens after Eric sends me the finished battery carrier to become the complete PhD-M6 pack.

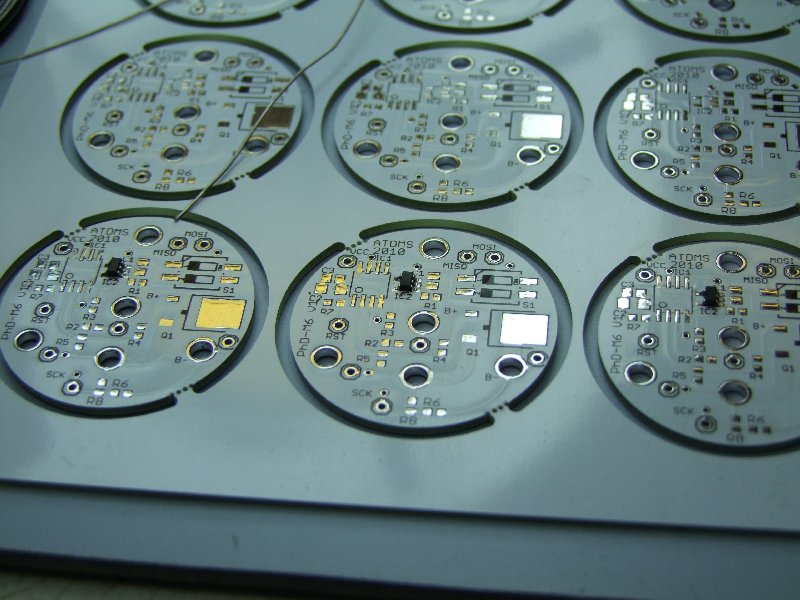

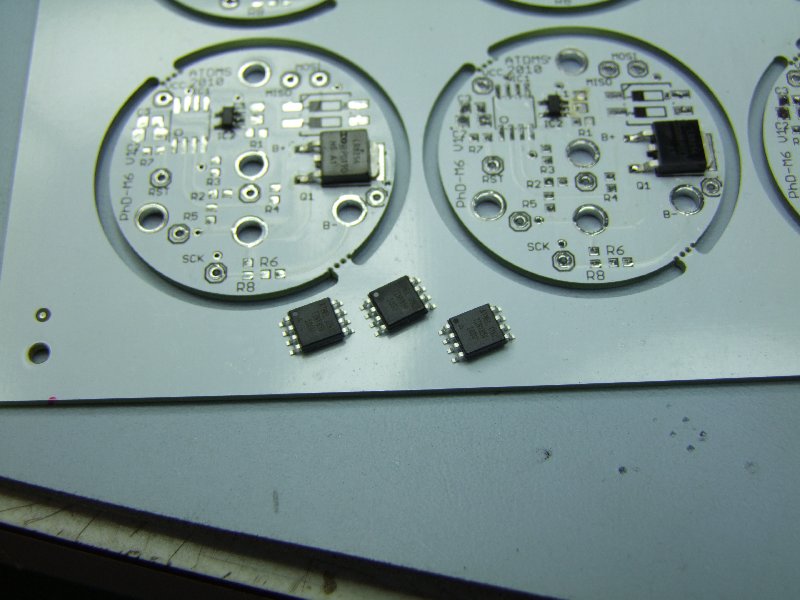

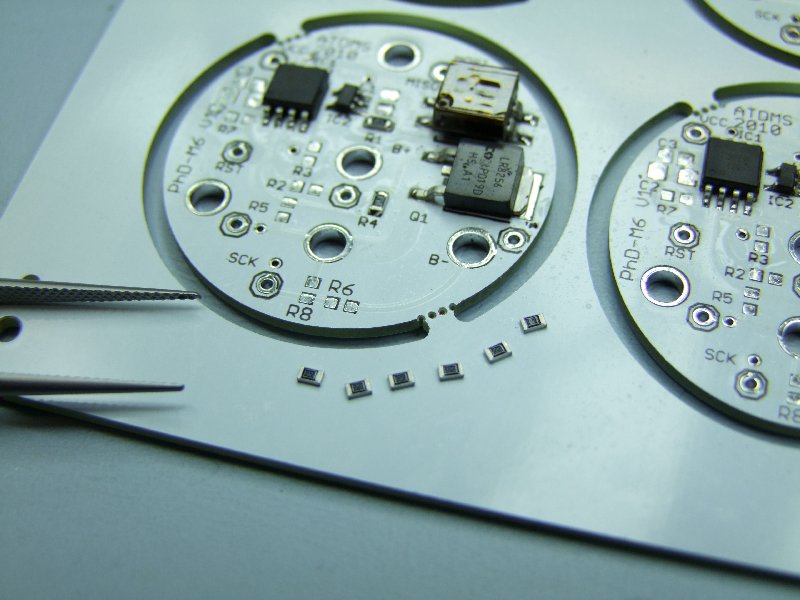

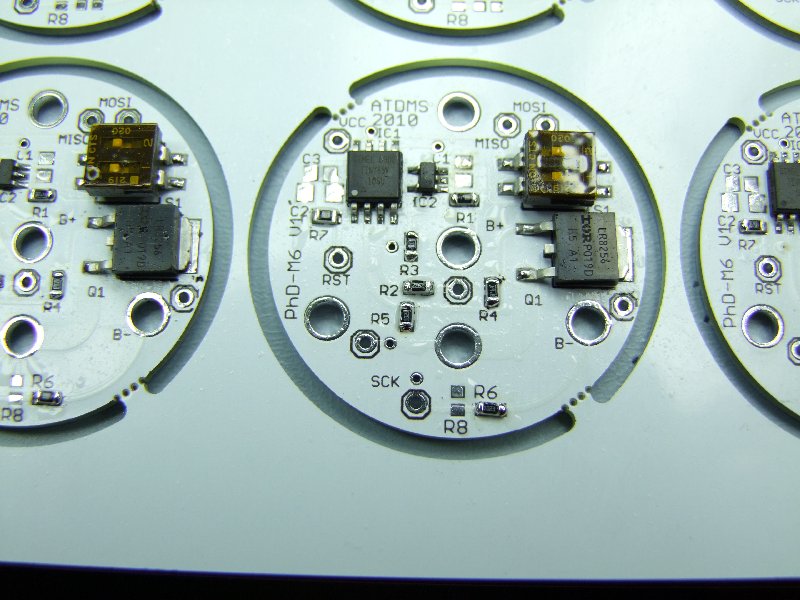

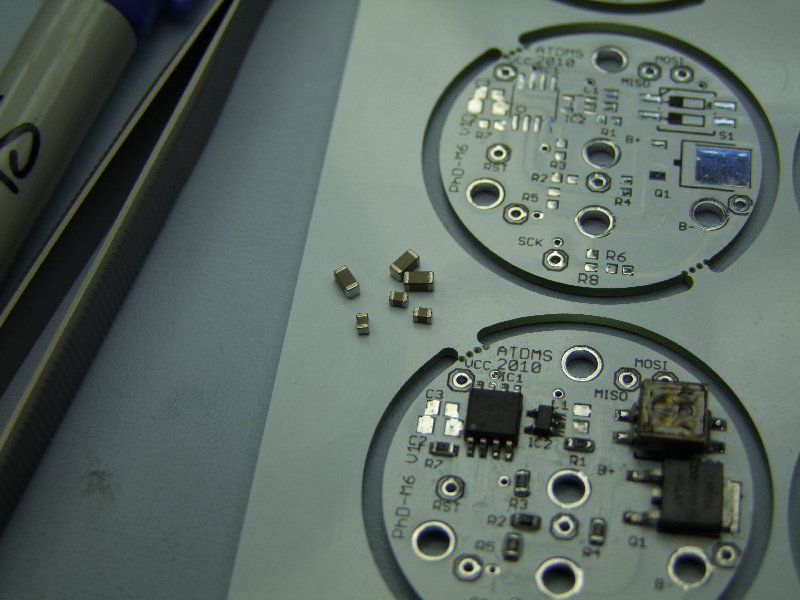

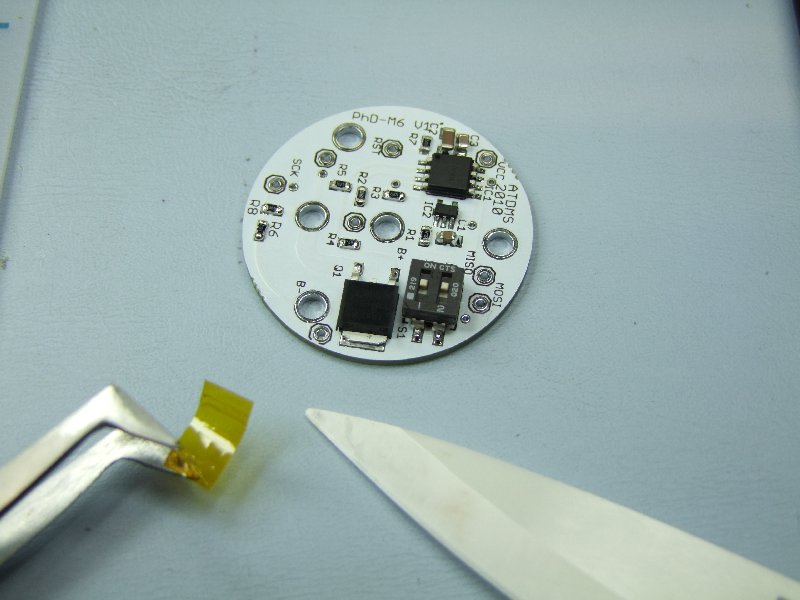

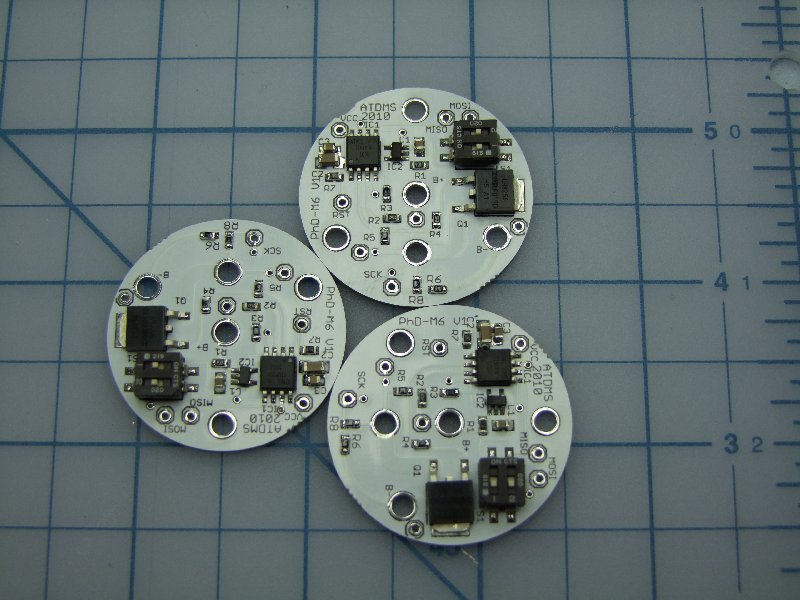

Here is the panel with the bare PhD-M6 production boards that I designed (again, kudos to Alan, Jimmy, and George for their help!):

These are the parts I got from Digikey for this board:

I am using a Metcal MX-500 with the stylus wand:

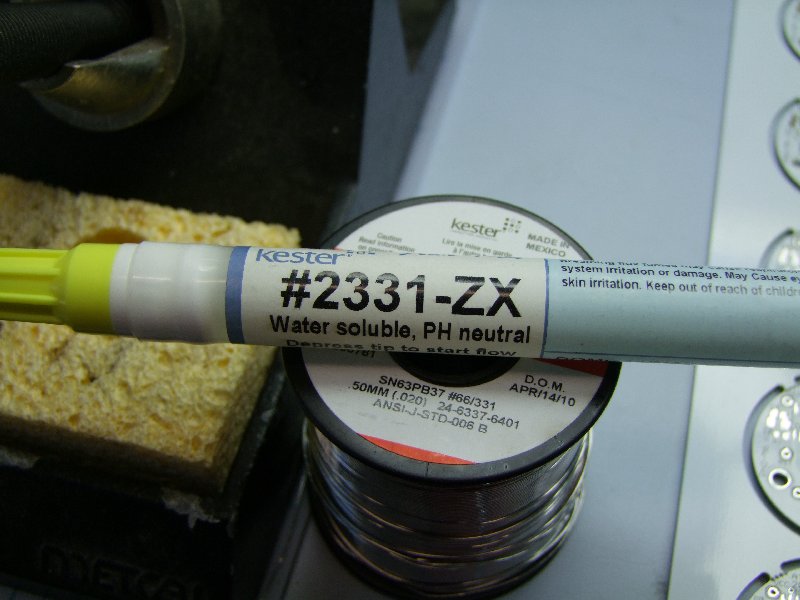

For solder I am using this outstanding Kester solder and flux pen:

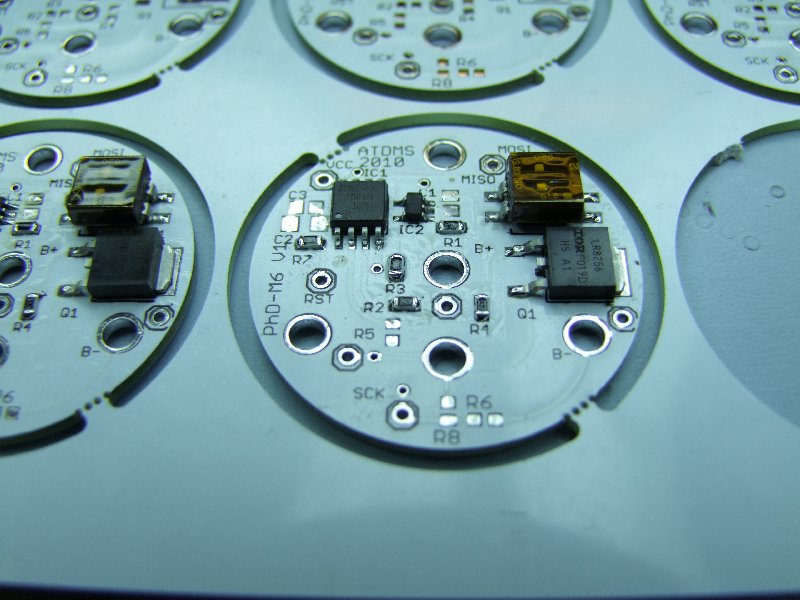

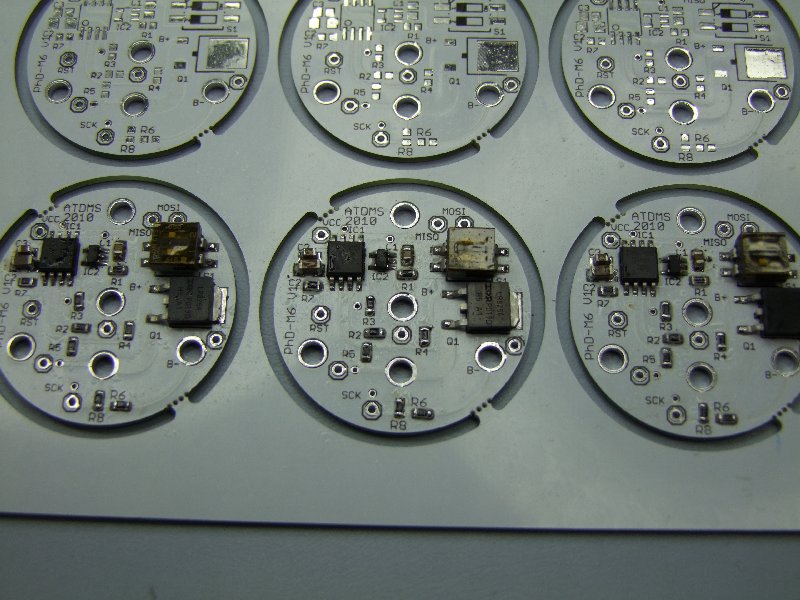

I will be updating the order as I build more and more of these, but first I start with the 5V Voltage regulator:

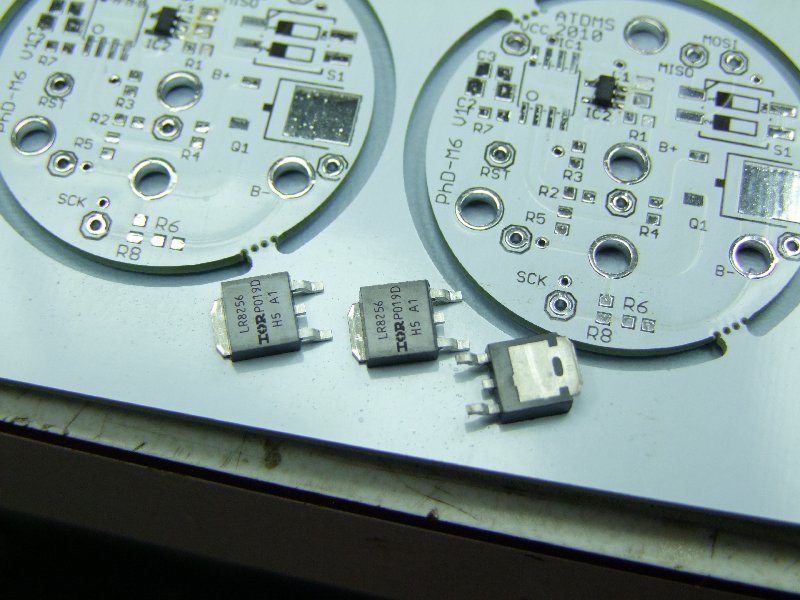

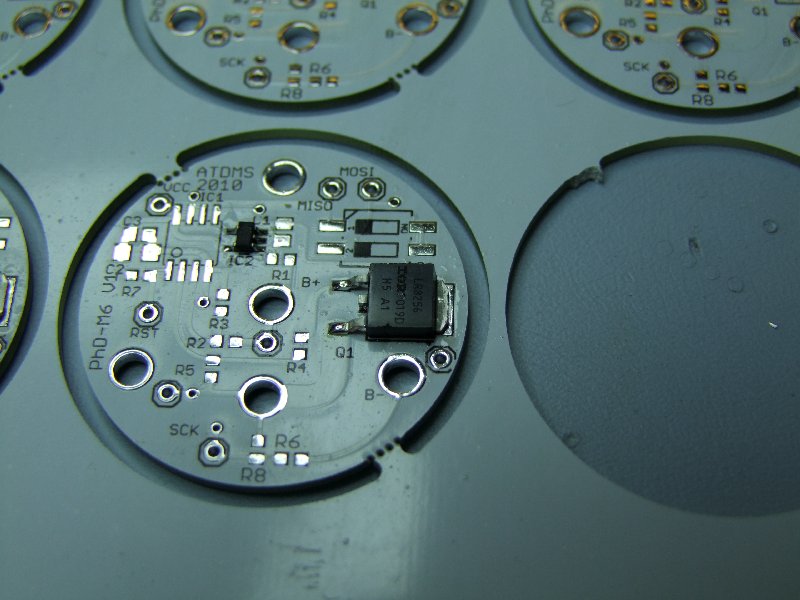

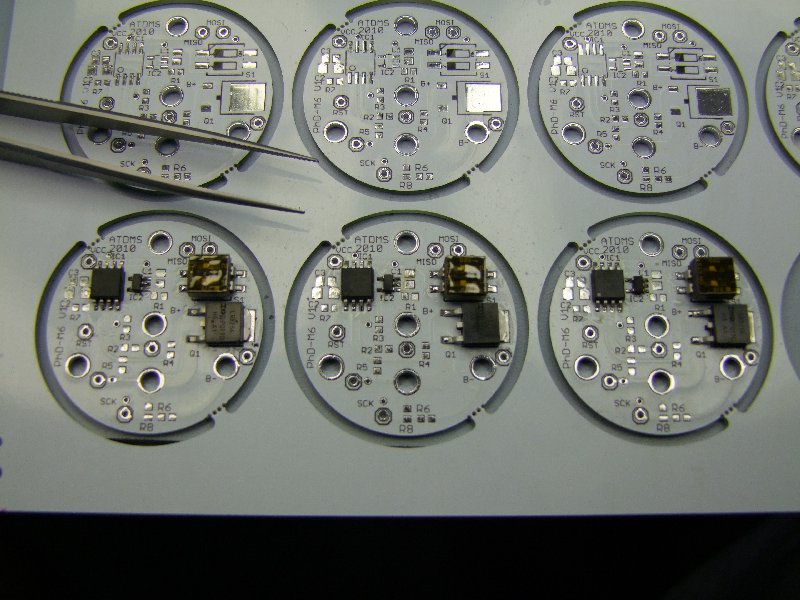

then the MOSFET:

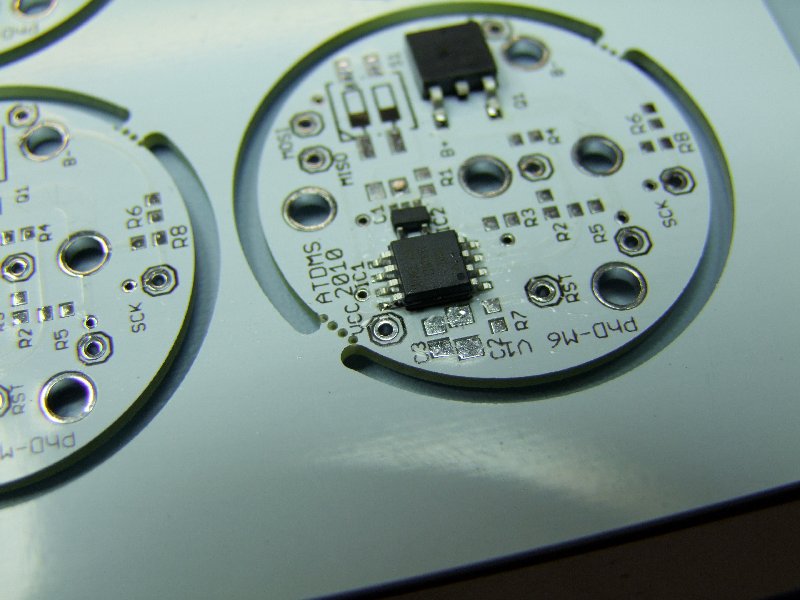

then the Tiny85:

then the DIP switch:

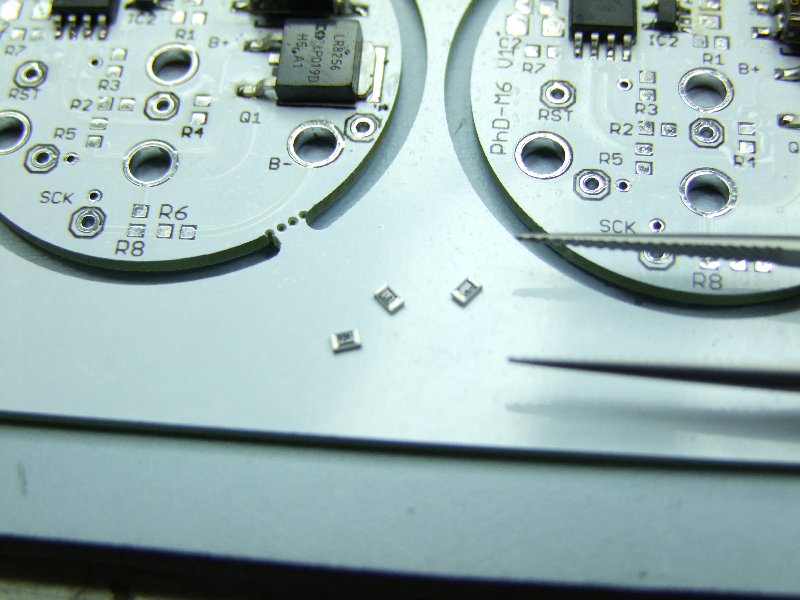

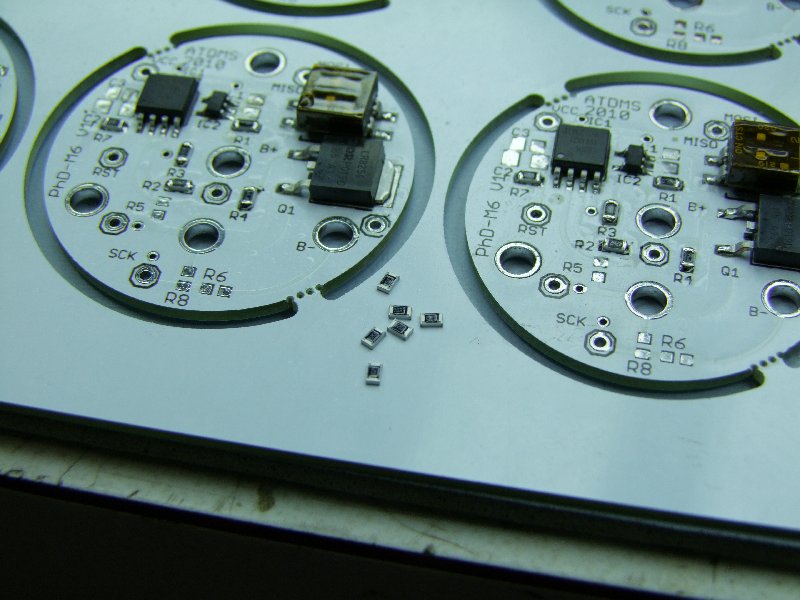

I then do the resistors - yes, they are that small (0805 to be exact):

more resistors:

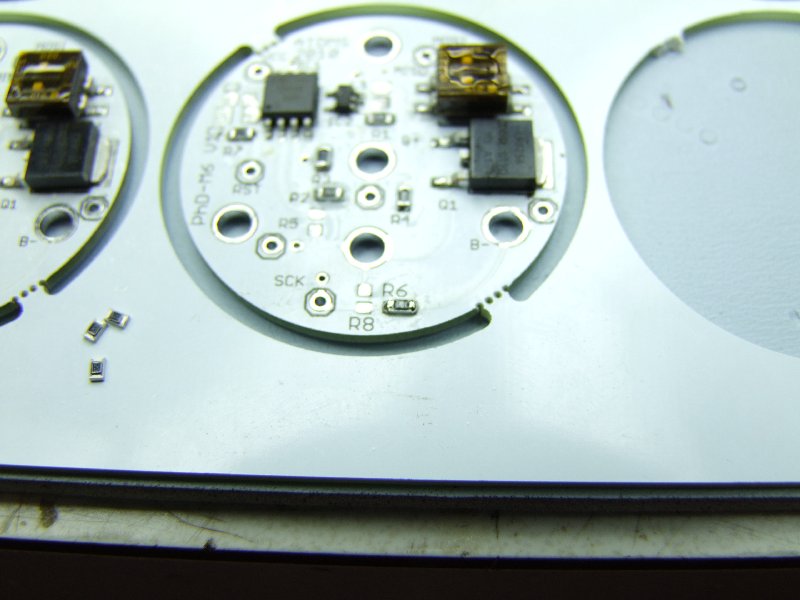

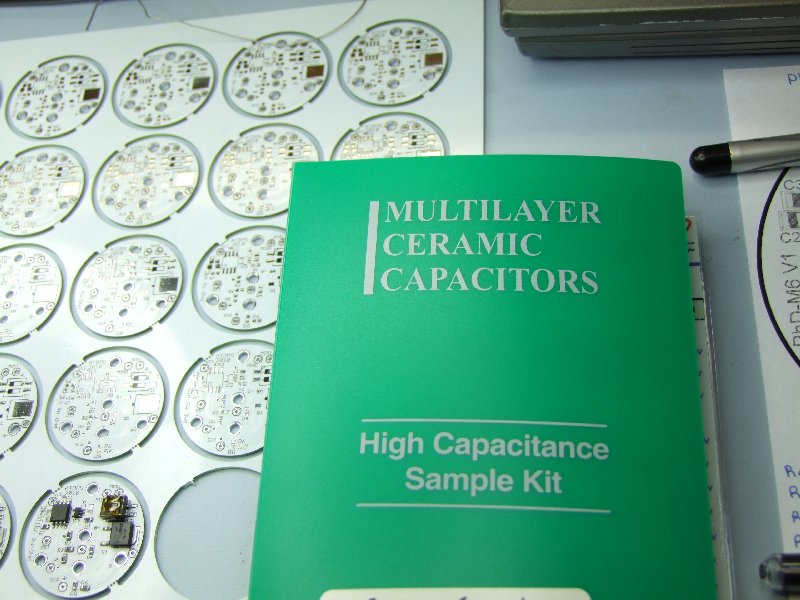

Then I move into the capacitors:

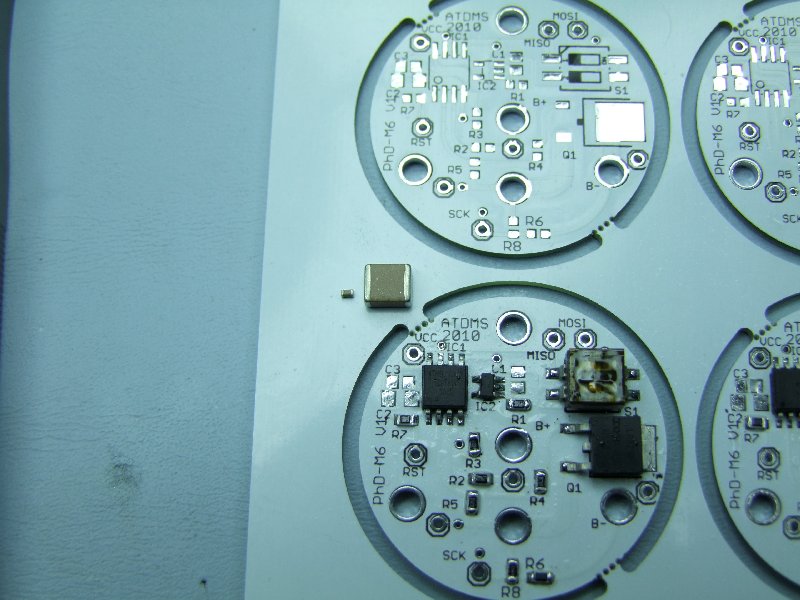

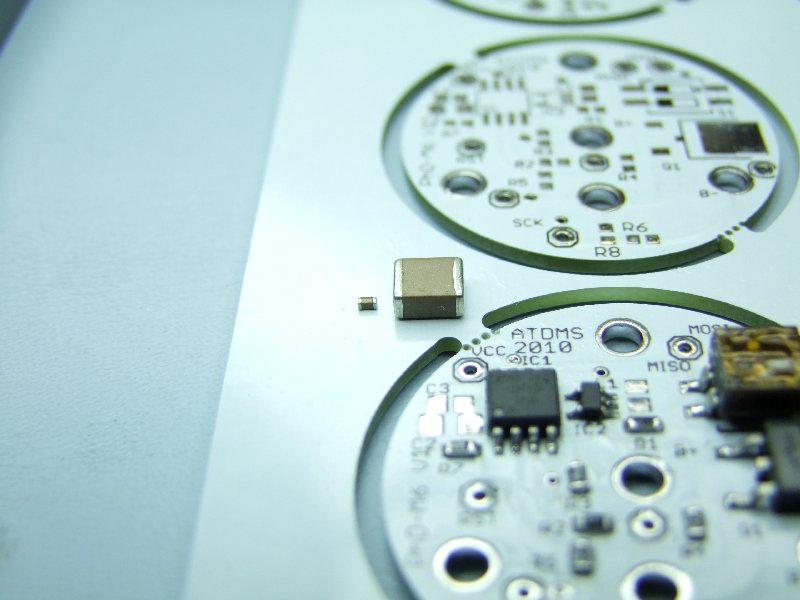

Trivia - which capacitor has a higher value? :devil:

(the small cap is a 1uF - the large one is a 100uF!):

But we don't need anything that big. These are the sizes I will be using:

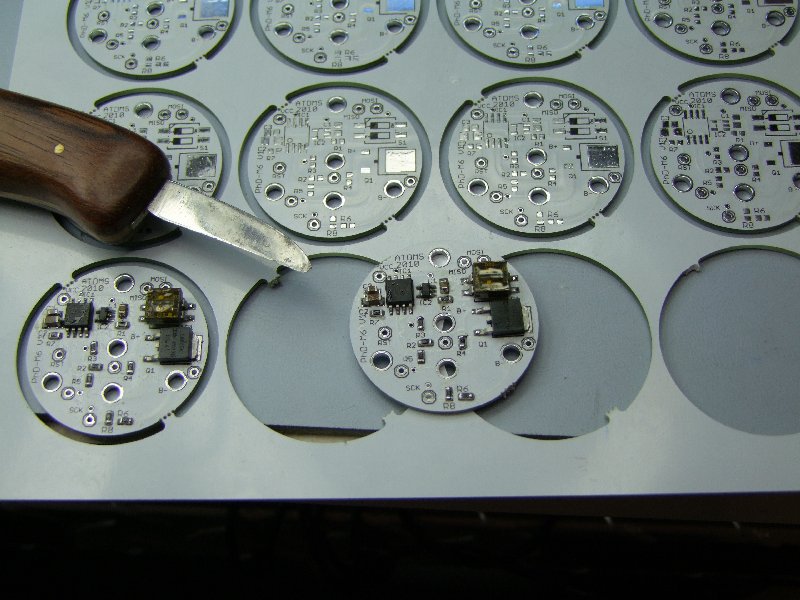

As you can see in the pictures, the board has been progressively getting more and more dirty with the flux. Since this water-soluble flux is somewhat corrosive, it MUST be cleaned. First I separate the finished boards from the panel:

Then to clean the boards in an ultrasonic water cleaner for 5 minutes:

Once they are ready, they need to be dried off:

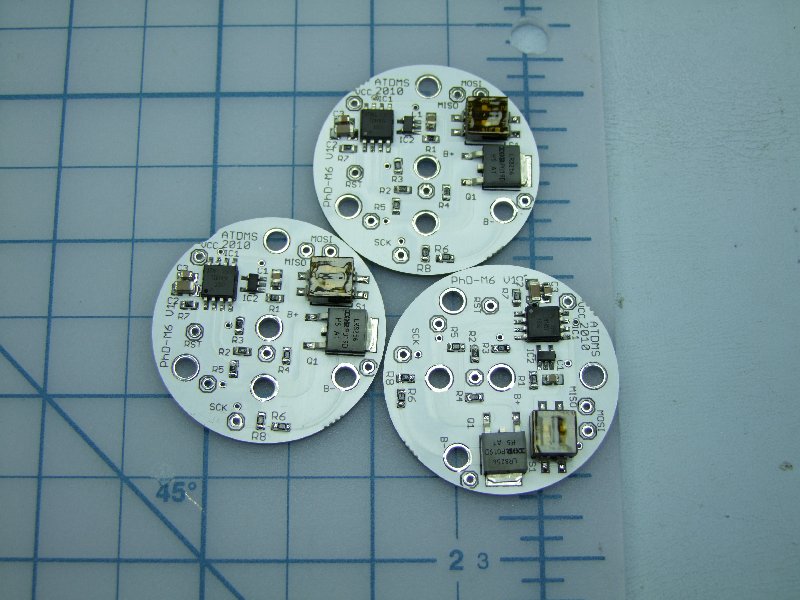

Nice and clean:

I first remove the cover that protects the switches from the "bath":

Now they are ready to be tested:

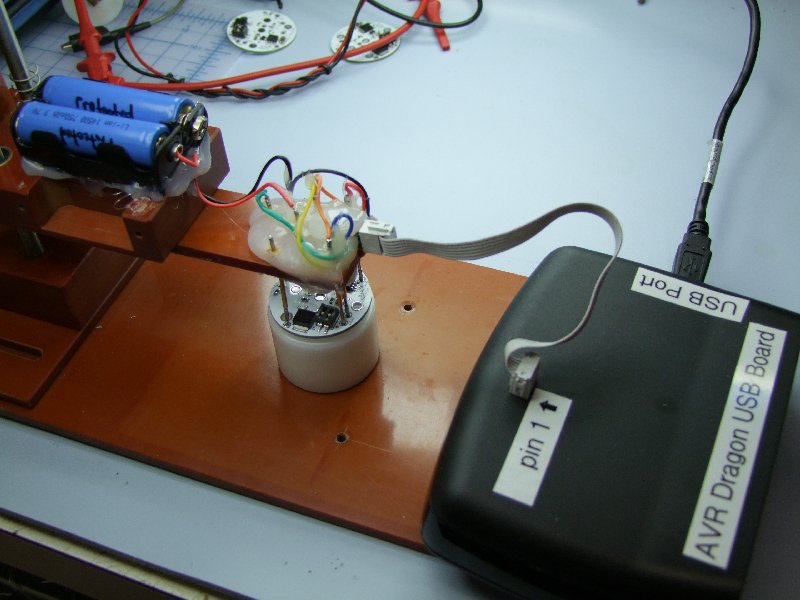

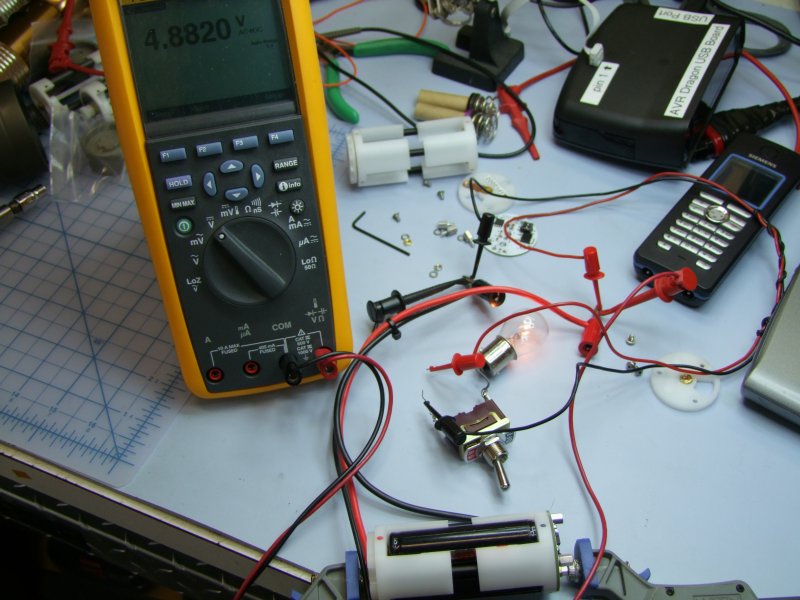

I first check them in my special fixture. Here I am using low current protected cells in case I have a short/problem. Assuming things are well, this fixture allows me to test the 5V regulator and verify that the AVR Dragon tool can read/talk to the Tiny85:

Once I can read the signature, I do the initial programming, set the fuses and lockout options, and then I am ready for the next step:

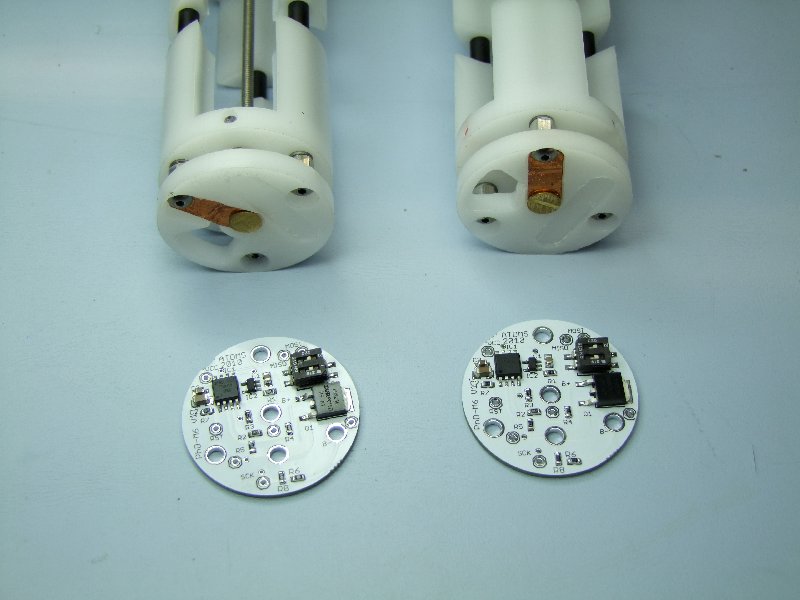

Here are the two prototype packs that are going out for field testing. One for Eric, and one for forum member leukos:

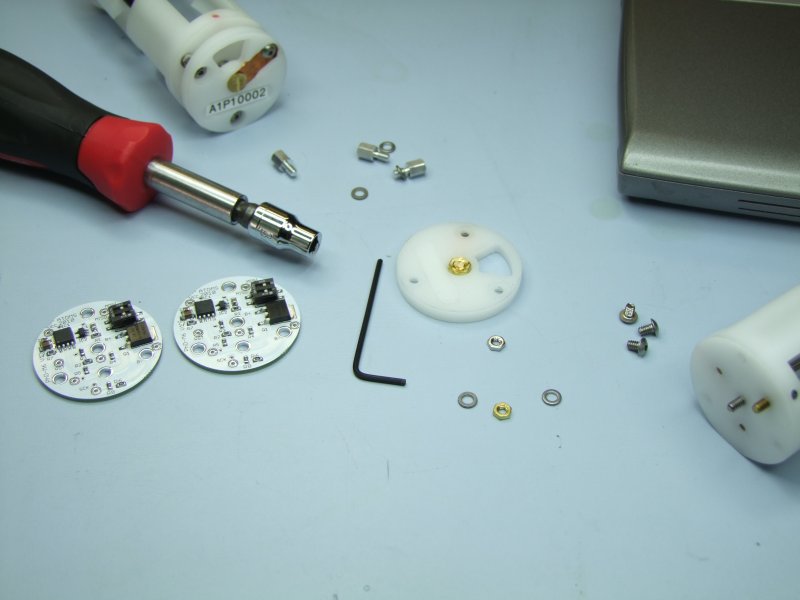

I disassemble the top of Eric's battery carrier:

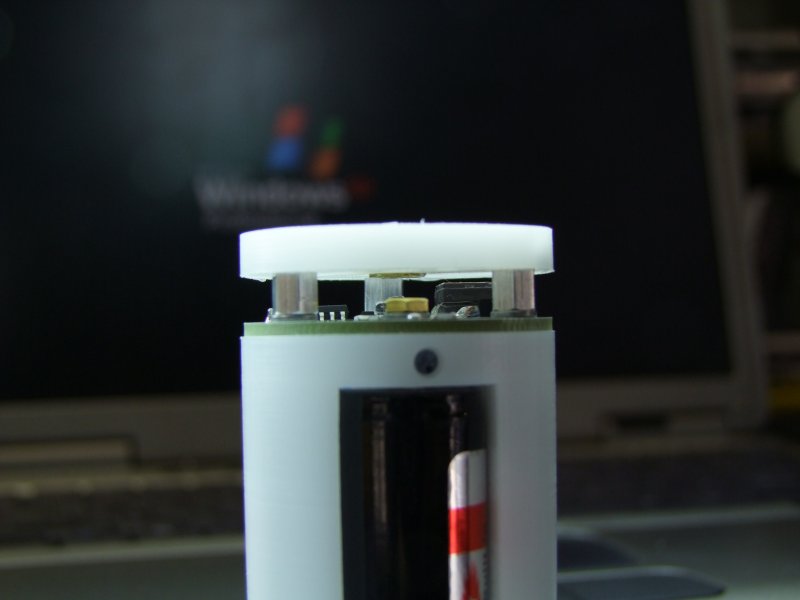

place the board and center:

install the outer screws/stand-offs:

then the center (Battery plus) and lower center (Battery minus) connections:

I then install the protected 17670 cells - NOTE that Eric clearly marks the Pos and Neg side for each of the 3 cells. The pack might be damaged if the cells are connected backwards!:

I first check the pack's voltage (note I am using my Son's Scooy-Doo band-aid for a boo-boo in my finger!) :

then I check the regulated DC voltage at the Tiny85:

Once the pack is running good, I then proceed to test what are the outputs, so that I can calibrate each pack with a small correction factor. This part is slow, but makes sure each regulator is as close as possible to the target voltages as possible.

Please note two things:

1) You can't measure the regulated output into a bulb with a normal True-RMS voltage meter. You need a special meter that can measure both the AC and DC components of the PWM signal, as True RMS meters only measure accurately at a duty cycle of 50%. Since the regulator varies the duty cycle to compensate for the battery as it drains, only a meter with AC+DC capability will give you the correct value.

2) The pack goes to sleep if there is no bulb across the pack. If you put a bulb across the pack, then the regulator will wake up and start regulating, which would then allow you to use your AC+DC meter to measure the actual RMS Voltage.

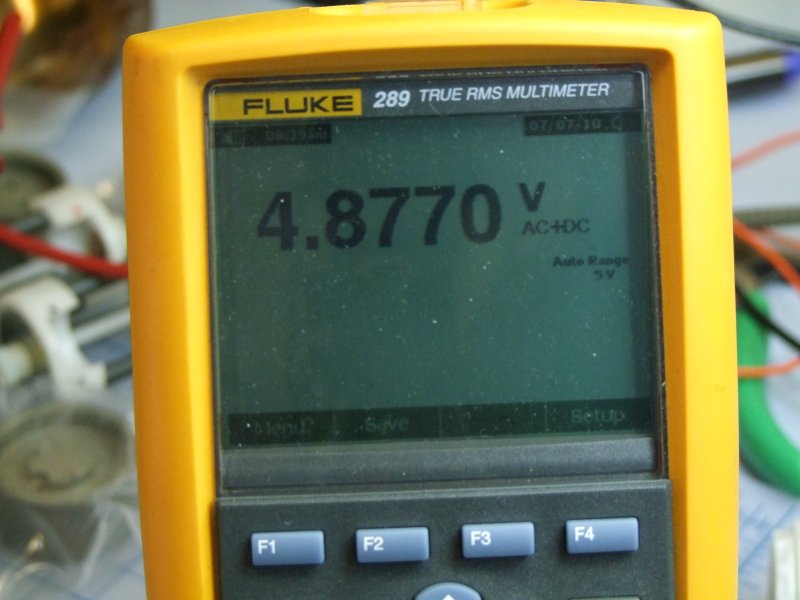

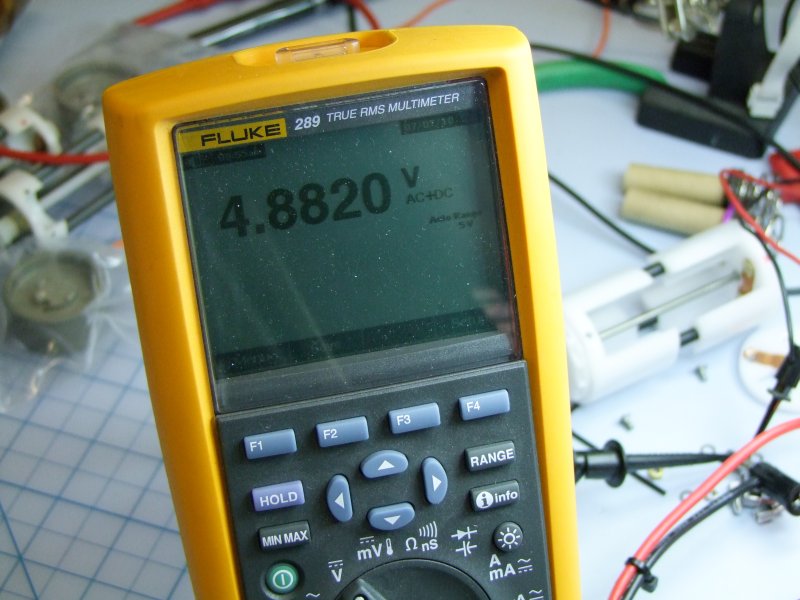

First test the 4.9 volt output - note that the output does vary a bit between photos as the regulator is constantly adjusting/compensating as the battery drains:

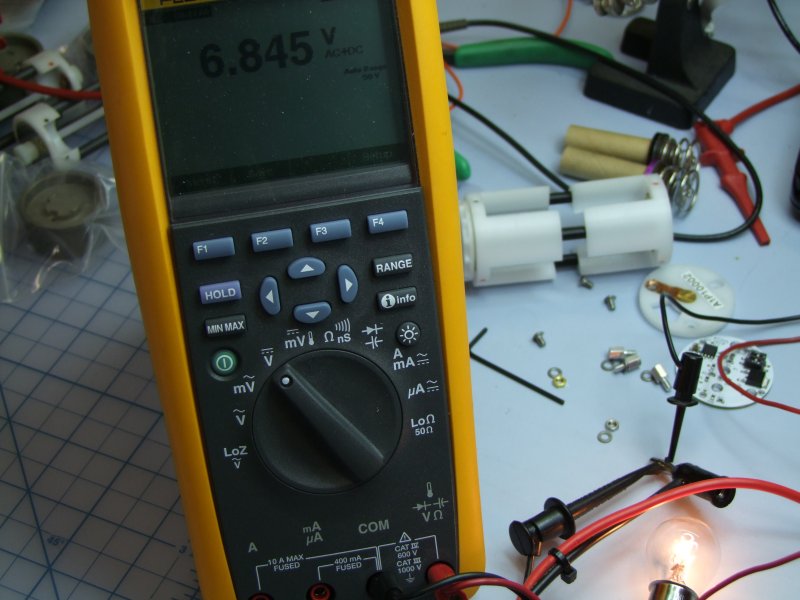

Then the 6.8 volt output:

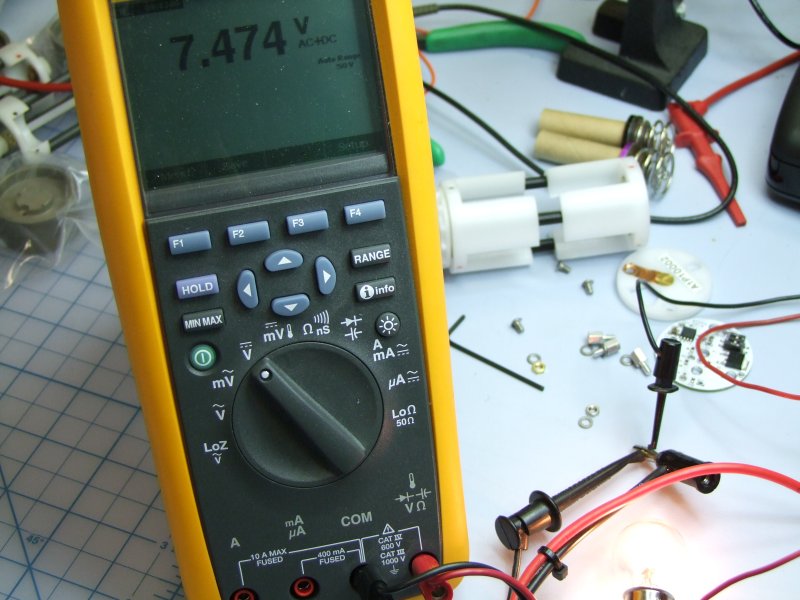

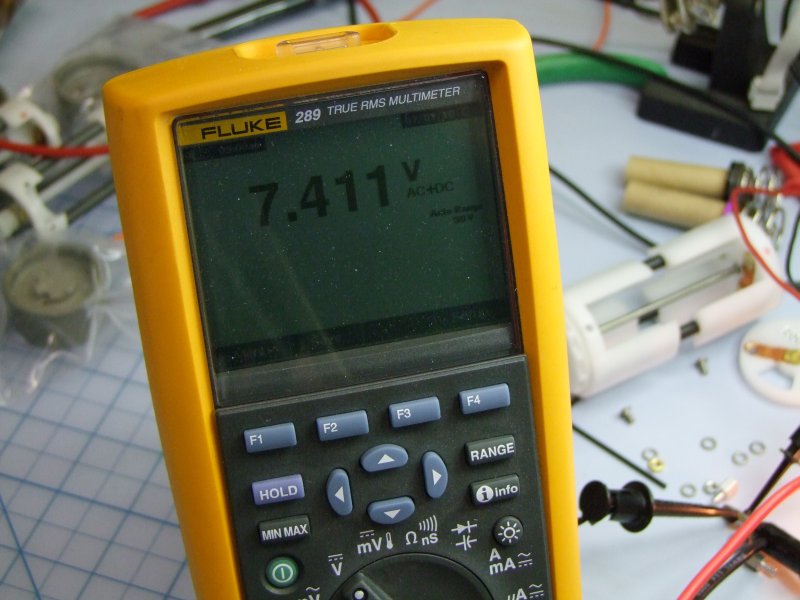

Then the 7.4 volt output:

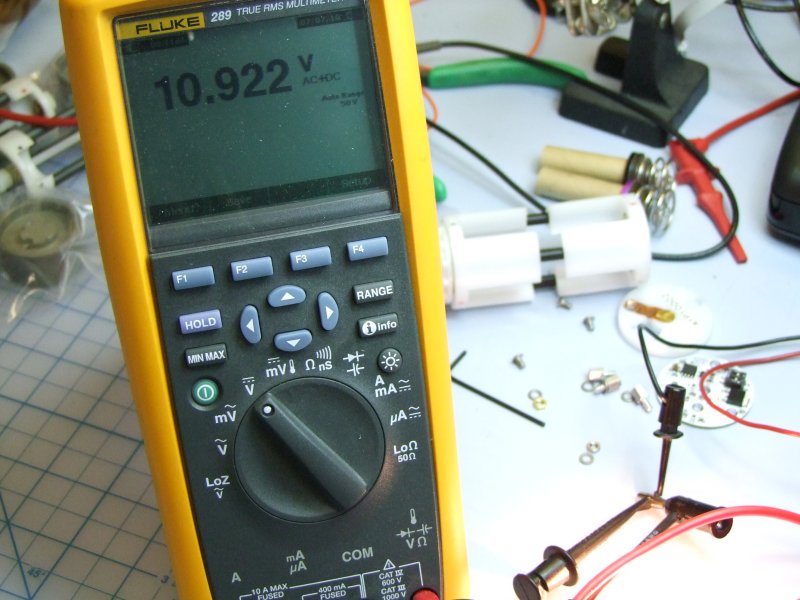

and the 10.8 volt output:

Then compare to the target:

Calculate an average compensation factor, and re-program the pack:

After calibration, these are the new outputs (4.9 volt target):

6.8 volt target:

7.4 volt target:

and 10.8 volt target:

Here is the completed and calibrated PhD-M6 pack:

I then set the DIP switch to HIGH-LOW, to select level 3, 7.4 volts, since I am testing with the N2 in my own M6:

Insert pack into M6:

and voila! - a 12 volt battery pack safely driving an N2 at a regulated 7.4 volts RMS:

I then finished the second pack:

That is it for now - thanks for watching

Here is the panel with the bare PhD-M6 production boards that I designed (again, kudos to Alan, Jimmy, and George for their help!):

These are the parts I got from Digikey for this board:

I am using a Metcal MX-500 with the stylus wand:

For solder I am using this outstanding Kester solder and flux pen:

I will be updating the order as I build more and more of these, but first I start with the 5V Voltage regulator:

then the MOSFET:

then the Tiny85:

then the DIP switch:

I then do the resistors - yes, they are that small (0805 to be exact):

more resistors:

Then I move into the capacitors:

Trivia - which capacitor has a higher value? :devil:

(the small cap is a 1uF - the large one is a 100uF!):

But we don't need anything that big. These are the sizes I will be using:

As you can see in the pictures, the board has been progressively getting more and more dirty with the flux. Since this water-soluble flux is somewhat corrosive, it MUST be cleaned. First I separate the finished boards from the panel:

Then to clean the boards in an ultrasonic water cleaner for 5 minutes:

Once they are ready, they need to be dried off:

Nice and clean:

I first remove the cover that protects the switches from the "bath":

Now they are ready to be tested:

I first check them in my special fixture. Here I am using low current protected cells in case I have a short/problem. Assuming things are well, this fixture allows me to test the 5V regulator and verify that the AVR Dragon tool can read/talk to the Tiny85:

Once I can read the signature, I do the initial programming, set the fuses and lockout options, and then I am ready for the next step:

Here are the two prototype packs that are going out for field testing. One for Eric, and one for forum member leukos:

I disassemble the top of Eric's battery carrier:

place the board and center:

install the outer screws/stand-offs:

then the center (Battery plus) and lower center (Battery minus) connections:

I then install the protected 17670 cells - NOTE that Eric clearly marks the Pos and Neg side for each of the 3 cells. The pack might be damaged if the cells are connected backwards!:

I first check the pack's voltage (note I am using my Son's Scooy-Doo band-aid for a boo-boo in my finger!) :

then I check the regulated DC voltage at the Tiny85:

Once the pack is running good, I then proceed to test what are the outputs, so that I can calibrate each pack with a small correction factor. This part is slow, but makes sure each regulator is as close as possible to the target voltages as possible.

Please note two things:

1) You can't measure the regulated output into a bulb with a normal True-RMS voltage meter. You need a special meter that can measure both the AC and DC components of the PWM signal, as True RMS meters only measure accurately at a duty cycle of 50%. Since the regulator varies the duty cycle to compensate for the battery as it drains, only a meter with AC+DC capability will give you the correct value.

2) The pack goes to sleep if there is no bulb across the pack. If you put a bulb across the pack, then the regulator will wake up and start regulating, which would then allow you to use your AC+DC meter to measure the actual RMS Voltage.

First test the 4.9 volt output - note that the output does vary a bit between photos as the regulator is constantly adjusting/compensating as the battery drains:

Then the 6.8 volt output:

Then the 7.4 volt output:

and the 10.8 volt output:

Then compare to the target:

Calculate an average compensation factor, and re-program the pack:

After calibration, these are the new outputs (4.9 volt target):

6.8 volt target:

7.4 volt target:

and 10.8 volt target:

Here is the completed and calibrated PhD-M6 pack:

I then set the DIP switch to HIGH-LOW, to select level 3, 7.4 volts, since I am testing with the N2 in my own M6:

Insert pack into M6:

and voila! - a 12 volt battery pack safely driving an N2 at a regulated 7.4 volts RMS:

I then finished the second pack:

That is it for now - thanks for watching