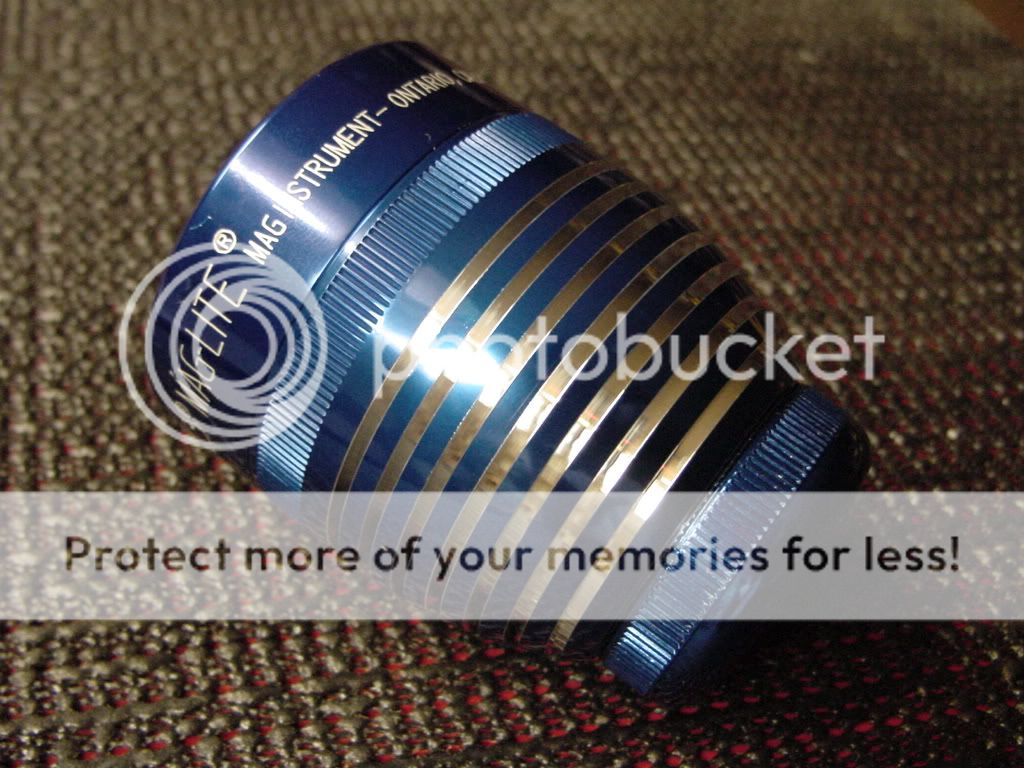

Alrighty...I'm in process on a Maglite bike light. I want to use the Mag head and find a cap to fit the hole in the back.

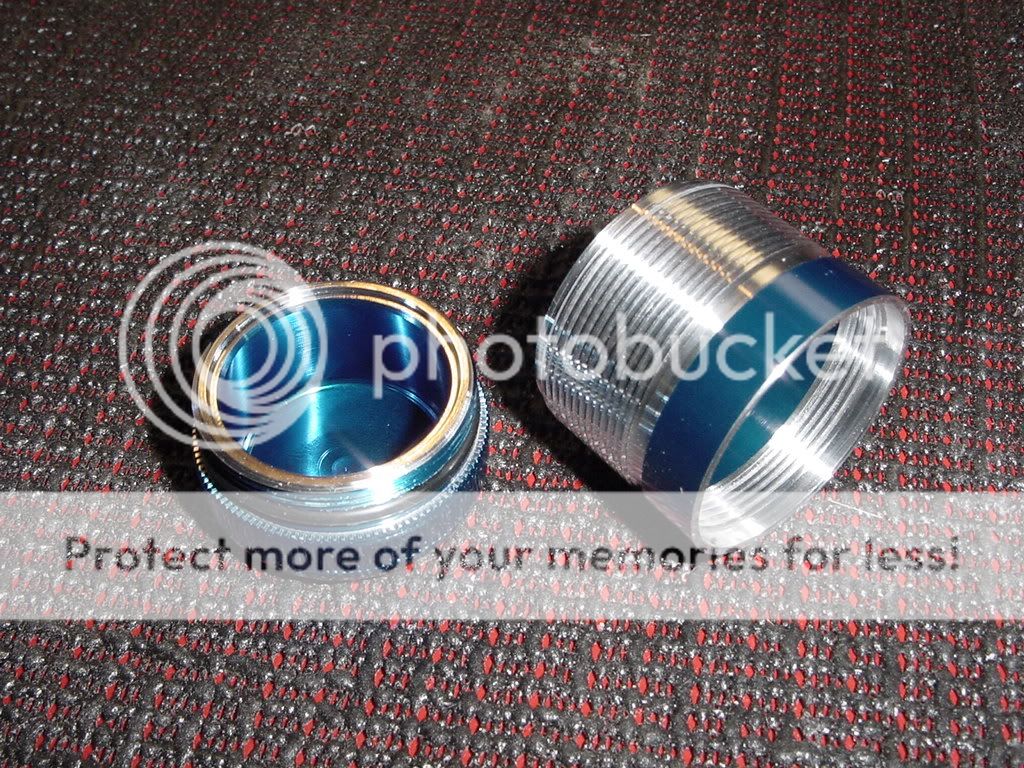

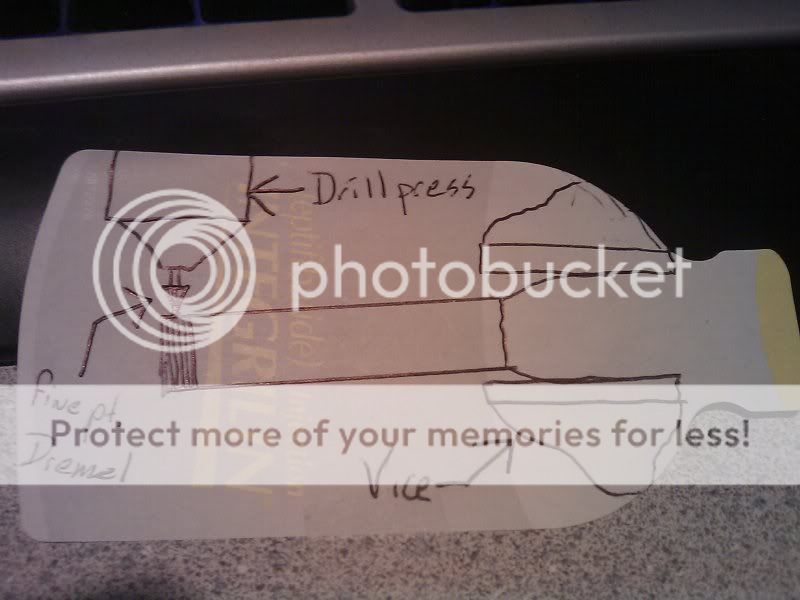

I could in theory cut the barrel of the light down to about 1/2" in length (keeping the stock tail cap) and thread the outside of the new barrel.

-How the crap do I find a die nut large enough to thread the barrel?

-- or --

-I could cut the barrel short on the near end and "tap" the I.S. so the stock cap fits in.

-- or --

-How could I make a cap to fit the hole that's removeable?

I could in theory cut the barrel of the light down to about 1/2" in length (keeping the stock tail cap) and thread the outside of the new barrel.

-How the crap do I find a die nut large enough to thread the barrel?

-- or --

-I could cut the barrel short on the near end and "tap" the I.S. so the stock cap fits in.

-- or --

-How could I make a cap to fit the hole that's removeable?

@ Chelboed

@ Chelboed