Hello,

It's been a long while since I've modified a flashlight and I'm out of date with current tech (last I knew the P7 was the LED to have).

My Milwaukee M18 led light is pretty sad and puts out minimal light. I'd like to upgrade the led and need suggestions on which LED and driver to use (18v input). Ideally I think it will come down to heat and efficiency since I'd like to be able to run this light for at least 30 minutes without worry of overheating. I think I'd like to stick with single mode, but am open to the idea of two mode (low and high).

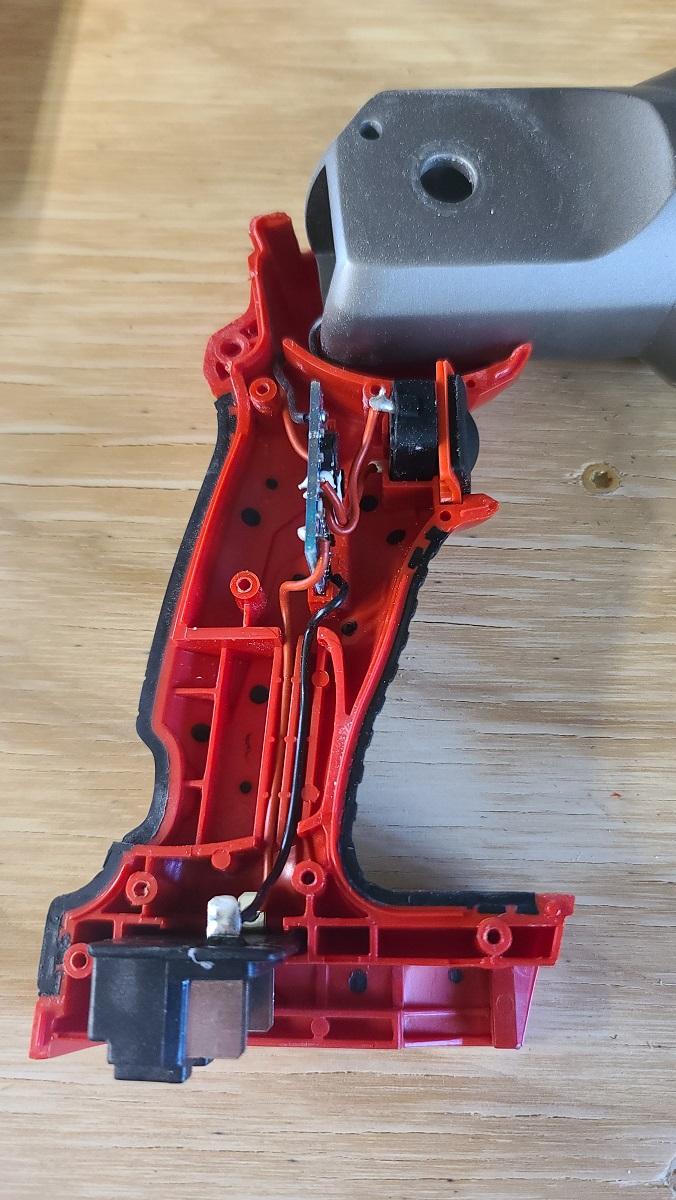

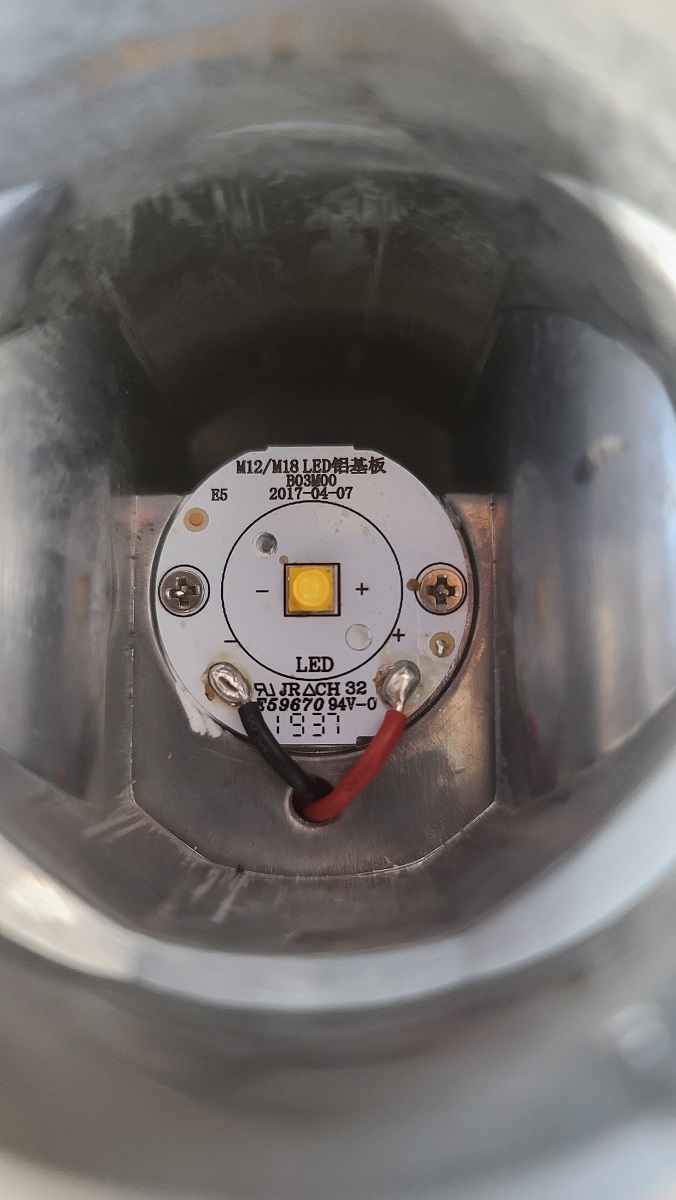

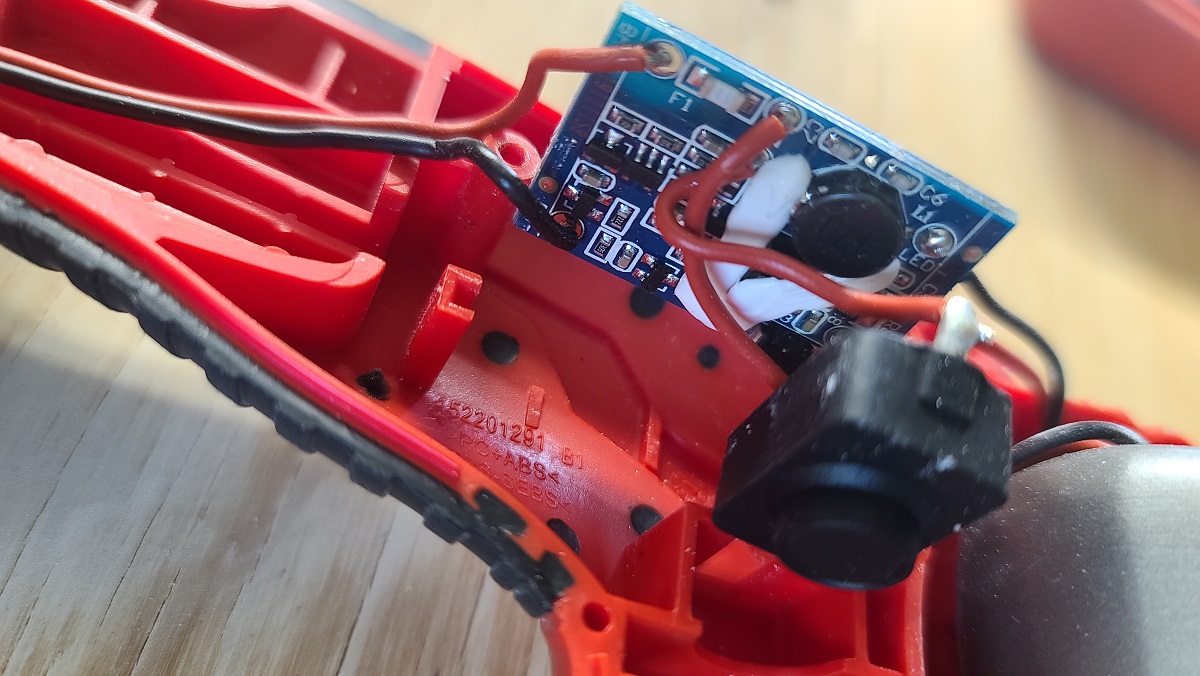

I attached some photos of the Milwaukee taken apart.

Is 1000 lumens possible without major upgrades to the heatsink? Thanks!

It's been a long while since I've modified a flashlight and I'm out of date with current tech (last I knew the P7 was the LED to have).

My Milwaukee M18 led light is pretty sad and puts out minimal light. I'd like to upgrade the led and need suggestions on which LED and driver to use (18v input). Ideally I think it will come down to heat and efficiency since I'd like to be able to run this light for at least 30 minutes without worry of overheating. I think I'd like to stick with single mode, but am open to the idea of two mode (low and high).

I attached some photos of the Milwaukee taken apart.

Is 1000 lumens possible without major upgrades to the heatsink? Thanks!