Hi all, new here. I wanted to ask yall a question about binning. I come from the overclocking world, and to me binning means something that I think might be different here. To me, binning is for computer processors. Not all processors are the same, even if they are the exact same make and model. Sometimes, certain processors overclock better if they came from a certain bin, usually a time period in the manufacturing. The ones a previous bin may only overclock to 3.3 Ghz, while most from the desired bin will overclock to 4.0Ghz. Is this the same for LED's? Are some LEDs going to put out more lumens than the others from a different bin? Please forgive my ignorance, but I am a giant noob to lighting. Thanks - Benny

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Please allow me to ask a noob question: Binning

- Thread starter BennyLava

- Start date

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

TorchBoy

Flashlight Enthusiast

Yes. (Edit: Hm, that was too short - 5 characters minimum per post.)

a Cree X-re P4 bin will go about 80lumens at 350ma

a Q5 bin will go 103lumens (if i recall correctly) at 350ma

an R2 will go 112 i think.

the later the alphabet (a being the earliest) and the bigger the number, the more lumens you will get for the same drive level.

currently, cree tops out at the R5 X-pg (which is in the titanium quark)

Crenshaw

a Q5 bin will go 103lumens (if i recall correctly) at 350ma

an R2 will go 112 i think.

the later the alphabet (a being the earliest) and the bigger the number, the more lumens you will get for the same drive level.

currently, cree tops out at the R5 X-pg (which is in the titanium quark)

Crenshaw

LEDninja

Flashlight Enthusiast

By over-clocking I assume you are looking at driving the LEDs harder than spec.

Heat kills LEDs so to overdrive an LED a much bigger heatsink would be needed.

There is no way to attach 5mm LEDs to a heatsink so they can not be overdriven. There are many threads of 5mm LED flashlights and household bulbs dying in 2 to 3 weeks instead of the 100,000 hours those LED are supposed to last. The recommendation has always been to drive them no more than 15 mA (some recommendations even 10 or 5 mA) instead of the 20 mA spec. In other words UNDER-clocking.

The transistors and pathways in a CPU gets smaller with each generation allowing for faster speeds. To avoid massive amounts of returns and lawsuits by owners of dead computers, the manufacturers are very conservative about the chip speed. By the time they realized the chip can run at faster speeds with no problems, the next generation has arrived and replaced it. So DIY can over-clock some and usually get away with it.

Until recently with power LEDs the die size is the same - 1mm*1mm. So there is no change in 'speed' of the LED due to die size.

The current flows through the LED continuously so there is no clocking involved. The lights that use PWM use the PWM to reduce light output. UNDER-clocking again.

Lumileds released the 1st 1mm*1mm die LED - the LuxI. Originally conservatively rated at 250 mA, later upgraded to 350 mA. 350 mA is still the reference point for most LEDs today.

The LuxIII with a slightly more efficient LED but more rugged build allowed 700 mA. This LED has been successfully run at 1000 mA.

The K2 is even more rugged allowing 1500 mA.

-

Then Cree came out with the EZ1000 die in the XRE. It produce a 2X increase in light, and a corresponding energy decrease in heat. Cree conservatively rated the LED at 350 mA. CPF & other modders promptly tried the 700 mA drivers that already exist for the LuxIII and the LED survived. After much further testing Cree upped the spec to 700 mA. The modders promptly ran their XREs at up to 1400 mA.

-

To make it cheaper for customers who just want to run their LEDs at 350 mA, Cree used an old 1/2 watt case and called it an XPE.

With the latest XPG 1.4mm*1.4mm die, Cree stayed with the cheaper XP case. With 3+ watts going into a case designed for 1/2 watt, I do not think there is much room for overdriving the XPG.

-

Lumileds also went the small LED case route with the Rebel. Rule of thumb - if your L0D-CE has a XRE inside you can try a 10440 Li-ion battery. If your L0D-CE has a Rebel inside don't bother.

There is less ability to massively overdrive the latest LEDs.

AFAIK there is no attempt to incrementally overdrive an LED based on bin. Here are the reasons:

Let us say you are using an XRE on a star that can take 350 mA for a P4 bin. You get an increase of ~5% in lumens per bin up and maybe a decrease of ~1% in reduction of heat. So going from a P4 to R2 bin will net you ~30% compounded in lumens and a 5% reduction of heat. So in theory you can get another 5% lumens if you overdrive the LED 5%. That works out to another 4 lumens. 112+4=116 lumens. Is it worth it? The variation in lumens in an R2 bin LED is 112-103=9 lumens. This is worse if you go from an Q5 to R2 where you get an additional 1 lumen.

Meanwhile if you attach the star with a P4 bin to a great big heatsink, you can run it at 700 mA and get 135 lumens. A big hunk of metal is a lot cheaper than a fancy driver with 1% or better components.

-

CPU speed is quartz clock based - very accurate. You can overclock very accurately. Drivers for LEDs are analog with components rated at:

1/2% - extremely expensive - we are not building NASA stuff;

1% - very expensive - we are not building hospital stuff;

5% - expensive - we are not building any kind of instruments;

10% - cheap - that is more like it for uncritical stuff like flashlight drivers.

So available drivers simply do not have the accuracy for bumping up the current to compensate for minor heat loss differences.

Heat kills LEDs so to overdrive an LED a much bigger heatsink would be needed.

There is no way to attach 5mm LEDs to a heatsink so they can not be overdriven. There are many threads of 5mm LED flashlights and household bulbs dying in 2 to 3 weeks instead of the 100,000 hours those LED are supposed to last. The recommendation has always been to drive them no more than 15 mA (some recommendations even 10 or 5 mA) instead of the 20 mA spec. In other words UNDER-clocking.

The transistors and pathways in a CPU gets smaller with each generation allowing for faster speeds. To avoid massive amounts of returns and lawsuits by owners of dead computers, the manufacturers are very conservative about the chip speed. By the time they realized the chip can run at faster speeds with no problems, the next generation has arrived and replaced it. So DIY can over-clock some and usually get away with it.

Until recently with power LEDs the die size is the same - 1mm*1mm. So there is no change in 'speed' of the LED due to die size.

The current flows through the LED continuously so there is no clocking involved. The lights that use PWM use the PWM to reduce light output. UNDER-clocking again.

Lumileds released the 1st 1mm*1mm die LED - the LuxI. Originally conservatively rated at 250 mA, later upgraded to 350 mA. 350 mA is still the reference point for most LEDs today.

The LuxIII with a slightly more efficient LED but more rugged build allowed 700 mA. This LED has been successfully run at 1000 mA.

The K2 is even more rugged allowing 1500 mA.

-

Then Cree came out with the EZ1000 die in the XRE. It produce a 2X increase in light, and a corresponding energy decrease in heat. Cree conservatively rated the LED at 350 mA. CPF & other modders promptly tried the 700 mA drivers that already exist for the LuxIII and the LED survived. After much further testing Cree upped the spec to 700 mA. The modders promptly ran their XREs at up to 1400 mA.

-

To make it cheaper for customers who just want to run their LEDs at 350 mA, Cree used an old 1/2 watt case and called it an XPE.

With the latest XPG 1.4mm*1.4mm die, Cree stayed with the cheaper XP case. With 3+ watts going into a case designed for 1/2 watt, I do not think there is much room for overdriving the XPG.

-

Lumileds also went the small LED case route with the Rebel. Rule of thumb - if your L0D-CE has a XRE inside you can try a 10440 Li-ion battery. If your L0D-CE has a Rebel inside don't bother.

There is less ability to massively overdrive the latest LEDs.

AFAIK there is no attempt to incrementally overdrive an LED based on bin. Here are the reasons:

Let us say you are using an XRE on a star that can take 350 mA for a P4 bin. You get an increase of ~5% in lumens per bin up and maybe a decrease of ~1% in reduction of heat. So going from a P4 to R2 bin will net you ~30% compounded in lumens and a 5% reduction of heat. So in theory you can get another 5% lumens if you overdrive the LED 5%. That works out to another 4 lumens. 112+4=116 lumens. Is it worth it? The variation in lumens in an R2 bin LED is 112-103=9 lumens. This is worse if you go from an Q5 to R2 where you get an additional 1 lumen.

Meanwhile if you attach the star with a P4 bin to a great big heatsink, you can run it at 700 mA and get 135 lumens. A big hunk of metal is a lot cheaper than a fancy driver with 1% or better components.

-

CPU speed is quartz clock based - very accurate. You can overclock very accurately. Drivers for LEDs are analog with components rated at:

1/2% - extremely expensive - we are not building NASA stuff;

1% - very expensive - we are not building hospital stuff;

5% - expensive - we are not building any kind of instruments;

10% - cheap - that is more like it for uncritical stuff like flashlight drivers.

So available drivers simply do not have the accuracy for bumping up the current to compensate for minor heat loss differences.

No overclocking computer processors was where I was coming from, and what I know of binning is only related to that. I was asking if LED binning is the same in that, a different batch of LED's are brighter (run at stock specs) then a previous or lesser batch of the exact same LED light. For computer processors you just cant raise the Ghz as high on a lesser binned processor. So I was just making sure that the word binning was being used in the same way, to signify what batch of the exact same thing, that they were from. I do not think I would run an LED brighter than normal cause I'm not that good yet and I would probly kill my expensive LED lol.

TorchBoy

Flashlight Enthusiast

Yes.

When I first got Cree LEDs I was very cautious about overclocking them but now I'm a little more relaxed about it. It reduces the brightness in the long term - something called lumen maintenance - but it's not a big deal really, because I'll probably have moved on to the next chip by the time it becomes noticeable.

When I first got Cree LEDs I was very cautious about overclocking them but now I'm a little more relaxed about it. It reduces the brightness in the long term - something called lumen maintenance - but it's not a big deal really, because I'll probably have moved on to the next chip by the time it becomes noticeable.

LED's are not binned on what they can handle.

They are driven at a set safe current, and the resulting voltage drop, output intensity, and chromaticity are tracked to determine which "bin" they get tossed into.

A better analogy would be the way flash memory is tested, not the way processors are tested.

They are driven at a set safe current, and the resulting voltage drop, output intensity, and chromaticity are tracked to determine which "bin" they get tossed into.

A better analogy would be the way flash memory is tested, not the way processors are tested.

ElectronGuru

Flashaholic

I come from the overclocking world, and to me binning means something that I think might be different here.

Processors and LEDs compare, but not as directly as you might think. Both are formed by imprecise processes, manufacturing that leaves a spectrum/distribution of desirable and undesirable traits. To many errors (undesirable traits) and its rejected. The ones left are good enough, but different from each other. Produce 1000 processors or LEDs and get 1000 slight variations.

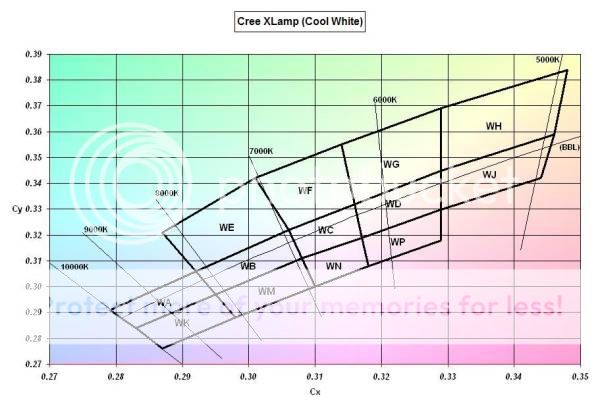

To be able to sell these and give customers some expectation of performance, all these variations are cut into groups, called bins. For computer chips, these are tolerance for speed (clocking). For LEDs, these are output color. Here is a standard bin chart:

The swaths of color are cut into big squares, each with a two letter code. These squares are essentially arbitrary. They could be half the size or twice the size. Somebody decided that these lines, defining these groups, would be the most helpful. The idea is that all the members of a given bin are similar enough. Ten LEDs with a bin of WH, for example, will all look all look 'near white' enough to be considered the same. Ten chips that test between 3.02Ghz and 3.08Ghz are all certified as 3.00Ghz capable.

The irony in all this is how the backbone of the digital age, silicone production, can really 'be' this analog.

Last edited:

LEDninja

Flashlight Enthusiast

No overclocking computer processors was where I was coming from, and what I know of binning is only related to that.

I was asking if LED binning is the same in that, a different batch of LED's are brighter (run at stock specs) then a previous or lesser batch of the exact same LED light.

For computer processors you just cant raise the Ghz as high on a lesser binned processor. So I was just making sure that the word binning was being used in the same way, to signify what batch of the exact same thing, that they were from. I do not think I would run an LED brighter than normal cause I'm not that good yet and I would probly kill my expensive LED lol.

They are driven at a set safe current, and the resulting ... output intensity, ... are tracked to determine which "bin" they get tossed into.LED's are not binned on what they can handle.

They are driven at a set safe current, and the resulting voltage drop, output intensity, and chromaticity are tracked to determine which "bin" they get tossed into.

A better analogy would be the way flash memory is tested, not the way processors are tested.

Most current power LEDs are rated at 350 mA. That is similar to saying all CPUs are tested and rated at 1GHz.

The LEDs are sorted into what they can do at 350 mA. This is similar to sorting CPUs that can run at 1 Gz into single core (Pentium, Atom); dual core (core dual); quad core (core 2 dual) bins.

... and chromaticity ...

CPUs do not feed data out in colours but I'll try to find an analogy. White LEDs are a phosphor on top of a blue (or violet or UV) LED core. The bluer LEDs have less phosphor, the warmer LEDs have more phosphor.

So a WA colour bin (extreme left of ElectronGuru's chart) has almost no phosphor. That is like a Celeron with no math chip nor internal cache.

A WC/WD/WG/WH colour bin is like a Pentium1, internal cache, math coprocessor.

A 5A colour bin (warm white, next chart) is like the latest CPUs with internal cache, math coprocessor, and graphics processor.

... resulting voltage drop ...

There is no equivalent analogy in a CPU as Vf an analog function. Lower Vf allow more current through from a fixed voltage source producing more light. It may allow too much current through burning out the LED.

Drive levels

Actual brightness levels in an LED of any one bin are controlled by current drive level. Similar to processor power controlled by clock speed.

There is one major difference. Going from 350 mA to 1000 mA (3X) will only increase the brightness 2X (80 to 160 lumens for an XRE P4 bin). Going from 1GHz to 3GHz will increase processor power 3X.

LuxI - 350 mA max. Overdrive not recommended.

LuxIII - 700 mA max. 1000 mA overdrive known.

Cree XR-E/SSC-P4 - 700 mA max. 1000 mA allowed on some chromaticity bins. 1400 mA overdrive known.

Cree MC-E/SSC-P7 - 2800 mA. Overdrive not recommended.

Cree XP-G - 1000 mA max. I would not try to overdrive it.

I do not have any info on the Cree XP-E or Luxeon Rebel.

bshanahan14rulz

Flashlight Enthusiast

you guys are overcomplicating the question I think. He wasn't so much looking for analogies as he was wondering about binning here compared to binning in the processor world. Answer: exactly. Cree will build the best chip they can, consistantly. Then they test the individual die and bin it.

And just like with cpu, to overdrive it, you need to ensure that it is well heat-sinked. Looks like you found a use for all that arctic silver 5 you have laying around

And just like with cpu, to overdrive it, you need to ensure that it is well heat-sinked. Looks like you found a use for all that arctic silver 5 you have laying around

Gunner12

Flashaholic

LED is built, LED is tested at a constant current for output, tint, and sometimes voltage at the current, and then placed in the respective bin. So a warm tint, high output, low Vf LED would be binned as warm, high output, and low vf, similarly, a cool, low vf, low output LED would be in another bin. Does that make sense?

:welcome:

:welcome:

Yeah thanks that helps. According to yall's analogies yeah they are binned the same way. As much as they can be, I mean. I didn't know if I would find any computer hardware aficionados here. But one of the posts kind of brings me to another thing I have noticed about the wide world of LED's...it's kinda weird how they call some LED's "warm tint" or "warm white", so as to compare it to the look, or the color of light that's shed by an incandescent. Well, I have ordered several different lights with this designation, and I haven't come across any that I would remotely compare to the look of "warmth" of an incandescent. Rather, the typical cold, sterile, artificial looking light of a white LED. Don't get me wrong, that's what I love about them. They look different. I just always wondered why they tried to equate it to warmth, when I can never see the same thing that they seem to be seeing. Then again, maybe I have just never ordered the right LED. Or perhaps I have been ordering them from a company that doesn't care so much about the accuracy of their labels?

Last edited:

ElectronGuru

Flashaholic

I just always wondered why they tried to equate it to warmth, when I can never see the same thing that they seem to be seeing. Then again, maybe I have just never ordered the right LED. Or perhaps I have been ordering them from a company that doesn't care so much about the accuracy of their labels?

LED color is a complex subject. And there are several historical and practical considerations making them more so. Give a glance here.

For starters, all measurements used to measure and describe LED color were created for or directly relate to incan color. Kelvin values, 'warm', even CRI which is used to measure how well light from LEDs render light, is actually a measure of how closely light from the measured LED performs in the same test compared to incan light pointed at the same sample.

On top of this is the nature of light from LEDs themselves. High powered emitters are blue based. Anything less blue is just unusual or the engineers have gone to a lot of trouble to make it so. Phosphors, for example, that convert some of the lumen energy in color conversion, at the expense of output.

Color wise, you have COOL, COOL WHITE, WHITE (aka neutral), WARM WHITE, WARM.

But because of the phosphors needed to create anything warmer than cool white, 3 of these 5 can be considered 'warm'. Case in point, Malkoff drop ins. You pay the same price for 20% less output to get a product called warm, that actually produces neutral light.

Personally, I've tried a true warm LED light and don't see the point. Its a sickly yellow thats worse than the blue the warm is trying to avoid. But thats personal. Everyone has a perception and option on this.

Yea, its complicated.

Last edited:

bshanahan14rulz

Flashlight Enthusiast

I had a beautiful Cree P3 7C xp-e from when they first came out, and it definitely was an incandesent color. Seems like true warm LEDs are hard to find, while neutral are much easier. It's still weird since there are very few real white light sources that we are used to. When we think of white, we actually think of a slightly yellow white, because everything that we've seen that was "white" was this color. It really comes down to personal preference. I had a 5A tint LED, and it was nice, with just a tinge of red. I now want a 5B tint LED, supposed to have the same small tinge of color, except instead of red, it is yellow :twothumbs

Personally, I've tried a true warm LED light and don't see the point. Its a sickly yellow thats worse than the blue the warm is trying to avoid.

Ha! I will have to try one of those now. I would like to see this sickly yellow. It might be a good one for deterring bugs, at least. I wish you guys could see the interior light that I put in my truck, so that you could name off what actual LED color it is. It was designated "warm white", but it's the coldest, deadest looking LED light that I have seen yet. It almost looks like it's too dreary to be in the cab of the truck, when it's on at night. But I like it! Still, I think it's been mislabeled.

TorchBoy

Flashlight Enthusiast

The only warm white LED I've seen (behind an opaque-ish lens) I mistook for an incandescent until someone pointed it out. They really aren't white as we know it, but it was surrounded by white LEDs at the time.

Similar threads

Latest posts

-

Got tips for Oveready BOSS / Triple V5.1file / programming issues?

- Latest: R.VanWinkle

-

-

-

-

-

-

-