sirpetr

Newly Enlightened

Hi folks, I am starting this thread about prototyping of a new powerful and lightweight headlamp. Its nearly exactly 1 year after introducing Lucifer headlamp. This new headlamp is smaller and lighter than previous model and has greater supply voltage flexibility as it can be used with one 18650 battery, two or a pack of four. Its meant for orienteering runners, adventurers or for mtb bikers as a superior helmet light. It should meet following specification:

Specification:

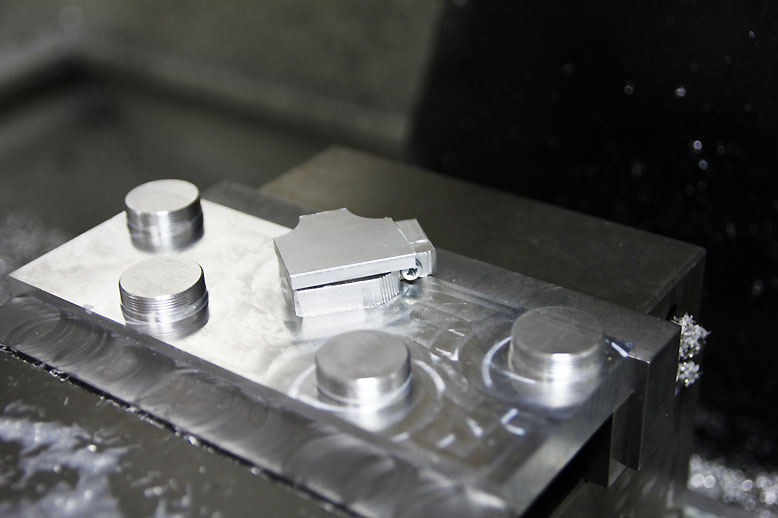

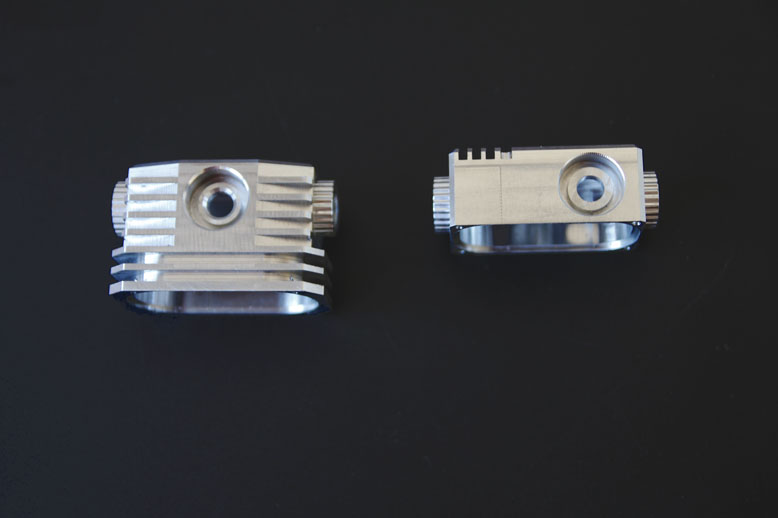

Body: cnc milled aluminium aircraft alloy hard anodized

Led: CREE XP-L, 5000K

Optics: TIR 16°

Battery: 1x18650 Panasonic 3400mAh unprotected (battery container is openable and has got protection circuit),

Electronics: our own buck converter made of discrete components and driven by Atmel 8-bit MCU with efficiancy up to 95%, has got temperature protection, overdischarge protection and protection against opposite polarity

Modes: 5 + blink

Lumens: 25 – 850lm (max. mode is not time limited)

Runtimes: 85 – 1 hour

Weight: 150gr.

Waterproofness: IPX-8rating (1m submersion)

Overall its very tiny package so there is nearly no space for electronics, switch and optics. Also waterproofness could be little hard. I would like to have the front cover made injenction moulded from ABS plastics but it could have some flex in it not to press o-ring hard enough to seal it perfectly. If if will not work, then I will made them from aluminium as well.

Here are some pictures of the first design model, hope you like it. I think about adding little more cooling ribs, but I will decide after I got real working headlamp in a hand a test it in real conditions.

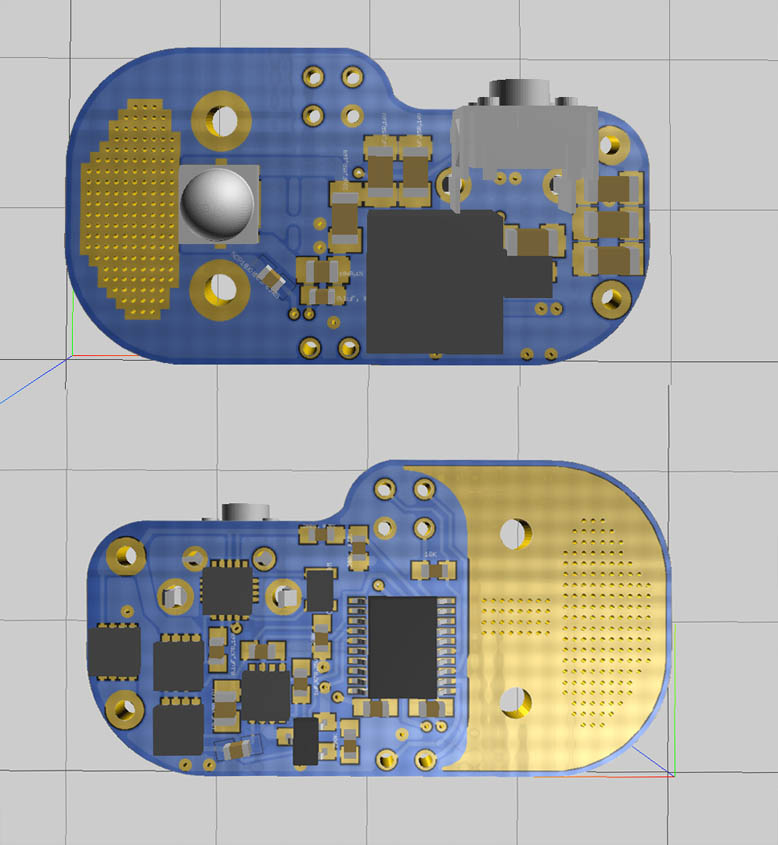

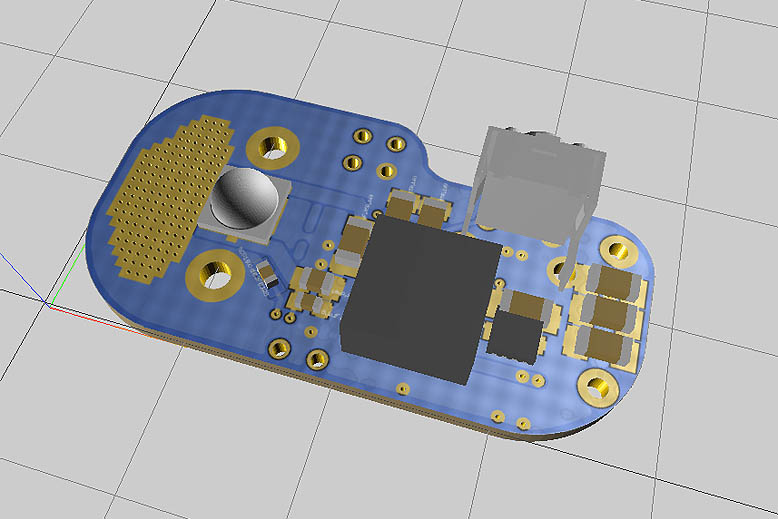

Electronics is my own electronics which I developed for regular Lucifer headlamp but with decent changes as it was originally made for 2 LEDs and also 2 battery cells in series. Now it should handle both 1-cell and 2-cell li-ion batterypacks. The main difference is faster PWM with higher resolution. Now its 62Khz with 10-bit resolution because of higher step down factor. Otherwise steps would be very high and noticeble. Faster clock should help me get there smaller inductor and leave place for decent 5x5mm switch.

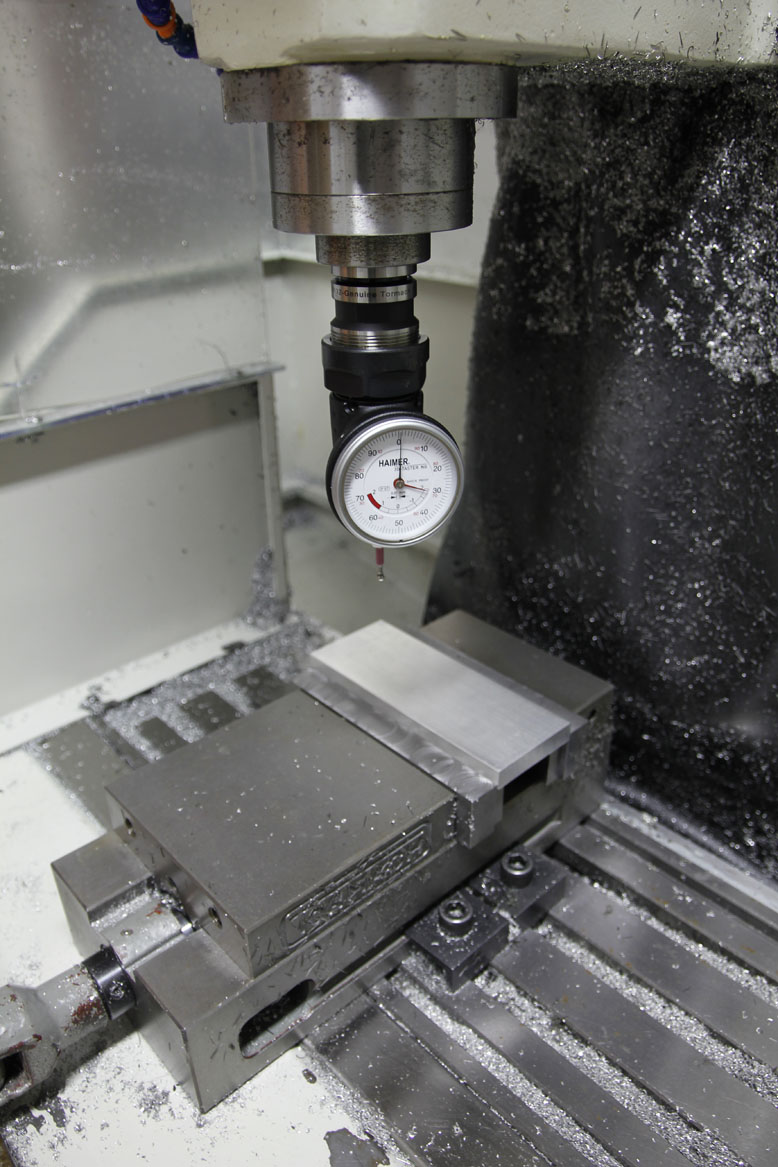

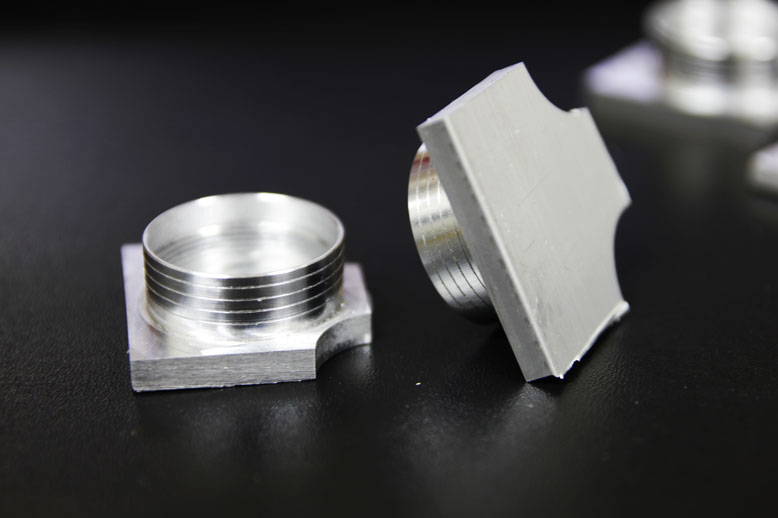

Battery container for 1 li-ion 18650 cell is basically tube with some milling and threading. Im curious how this will work as I dont have any lathe, only a cnc mill – which is not best choice for this kind of things. Sealing will be done with O-rings as any other flashlight out there.

Design:

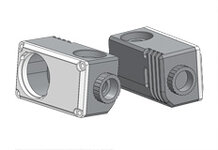

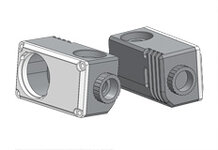

Weight 18.34gr

Weight 18.34gr

Weight 8.55gr

Weight 8.55gr

Crosssection of battery container with battery, protection circuit and springs inside

Crosssection of battery container with battery, protection circuit and springs inside

Specification:

Body: cnc milled aluminium aircraft alloy hard anodized

Led: CREE XP-L, 5000K

Optics: TIR 16°

Battery: 1x18650 Panasonic 3400mAh unprotected (battery container is openable and has got protection circuit),

Electronics: our own buck converter made of discrete components and driven by Atmel 8-bit MCU with efficiancy up to 95%, has got temperature protection, overdischarge protection and protection against opposite polarity

Modes: 5 + blink

Lumens: 25 – 850lm (max. mode is not time limited)

Runtimes: 85 – 1 hour

Weight: 150gr.

Waterproofness: IPX-8rating (1m submersion)

Overall its very tiny package so there is nearly no space for electronics, switch and optics. Also waterproofness could be little hard. I would like to have the front cover made injenction moulded from ABS plastics but it could have some flex in it not to press o-ring hard enough to seal it perfectly. If if will not work, then I will made them from aluminium as well.

Here are some pictures of the first design model, hope you like it. I think about adding little more cooling ribs, but I will decide after I got real working headlamp in a hand a test it in real conditions.

Electronics is my own electronics which I developed for regular Lucifer headlamp but with decent changes as it was originally made for 2 LEDs and also 2 battery cells in series. Now it should handle both 1-cell and 2-cell li-ion batterypacks. The main difference is faster PWM with higher resolution. Now its 62Khz with 10-bit resolution because of higher step down factor. Otherwise steps would be very high and noticeble. Faster clock should help me get there smaller inductor and leave place for decent 5x5mm switch.

Battery container for 1 li-ion 18650 cell is basically tube with some milling and threading. Im curious how this will work as I dont have any lathe, only a cnc mill – which is not best choice for this kind of things. Sealing will be done with O-rings as any other flashlight out there.

Design:

Weight 18.34gr

Weight 18.34gr Weight 8.55gr

Weight 8.55gr  Crosssection of battery container with battery, protection circuit and springs inside

Crosssection of battery container with battery, protection circuit and springs inside

Last edited: