Re: Why dont use a Led in DD???

Bigger capacity-to-current-draw ratio, and a better battery chemistry would help. Right now you're pulling out TONS of power from your batteries. If you increase that ratio, and get a nice flat discharge-curve chemistry (LSD NiMH, NiCd, Li-Ion), then you'll have near-regulated-type output with a long tail at the end of battery life.

Agreed, a 5mm led custom flashlight maker I was related to used a larger than normal resistor and under-drove his doubled leds to half effect. Of course, the single 1/4 watt resistor was on the ragged edge of overheating, but he was counting on short occasional activation cycles and his stuff was by no means 100% duty cycle.

On the plus side, the design was wicked cheap and had excellent runtime characteristics for the first 1/3 of the battery life. When you're looking at 10-50 hours of peak runtime capacity with no real damage to the emitters whatsoever EVER, who cares if you throw away a set of alkalines once in a while... right?

It was sort of regulated without a real driver circuit

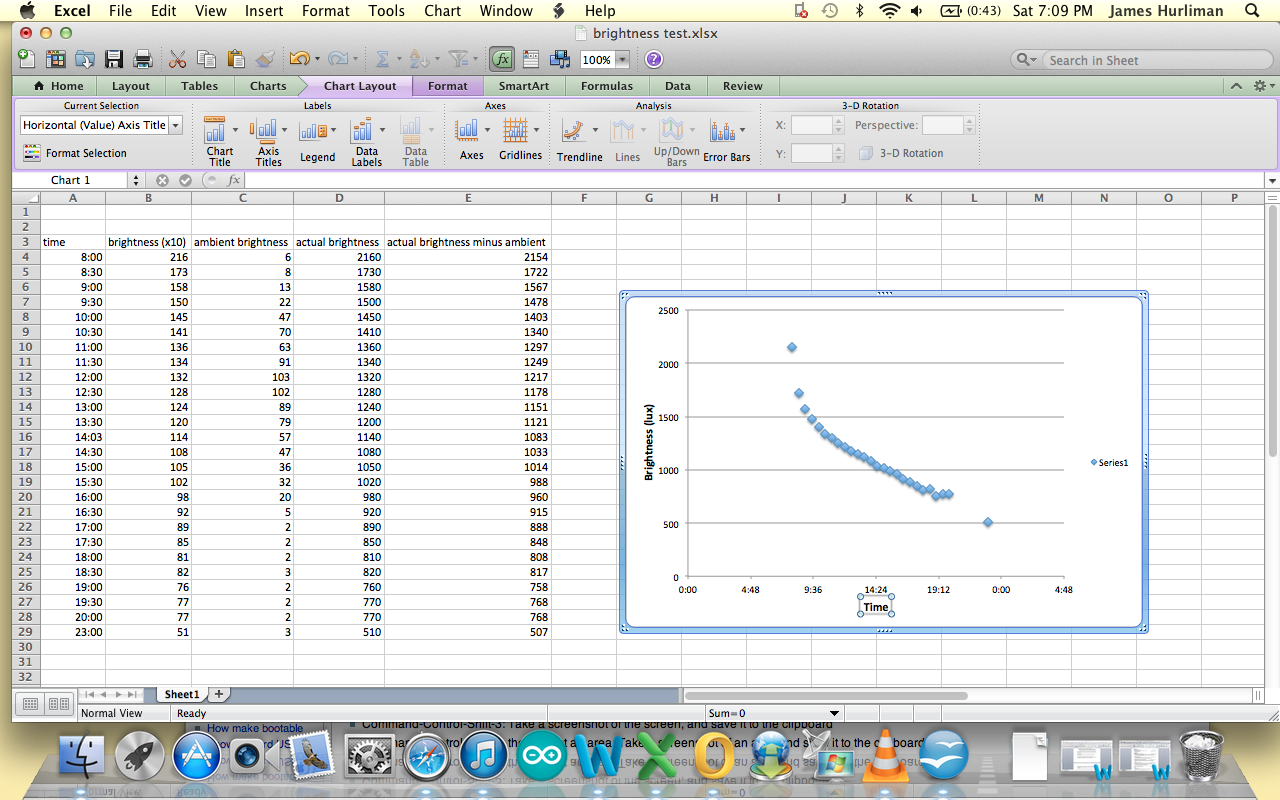

Side note: I really, really liked the guy. There's only one thing I've ever said to him that I wish I could take back and strangely it had to do with flashlights. No editing posts in real life, right? His flashlight design was actually pretty sweet and he even tested them with a lux meter. I said the wrong thing once about an experimental design that I helped build and it was taken the wrong way. I also made him mad by opening the wrong door a couple of times. I had no idea why it made him mad and he wouldn't explain. I'd just screwed up his runtime versus lux test.

He was my first exposure to high UV xenon-filled arc light and didn't even tell me anything or warn me about it, just that "your eyes will hurt if you leave this panel open, here have a margarita." I miss him a surprising amount.

Damn! I'm getting all sentimenal over an LED forum post. Wow! Didn't see that one coming! :mecry:

Life is short. Too short to say the wrong thing IRL.