Progress update--a very minor one.

First, the hand is healing well, the stitches come out on Wednesday. Thanks for all your well wishes--they seem to have helped.

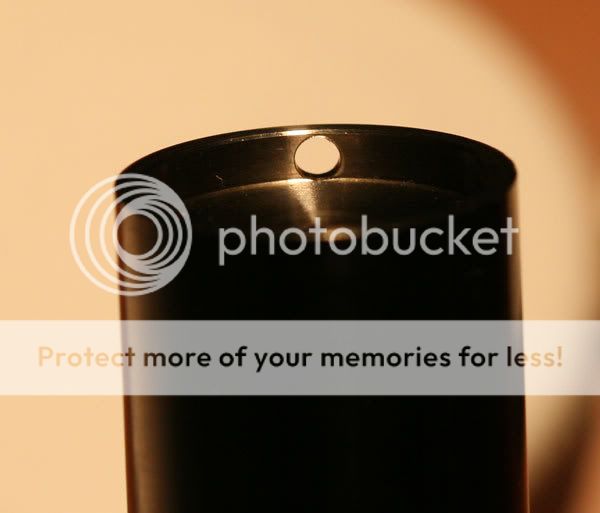

One of the things that has held this up for some time is that I encountered a problem trying to put the first part of the split ring hole into the tail of the battery tube:

Unfortunately, I used what I had on hand for tooling, namely my ball end mill that had done so well with the grooving shown in a previous post. But as the ball end mill was almost through, it broke, leaving this nice protrusion:

I'm not sure what caused the problem, but first and foremost is that I was not using the right tool--it should have been a drill, not an endmill.

Now I really didn't know what to do, so I turned to another forum for some advice, the

Practical Machinist, which is to machining as CPF is to flashaholics. Posted my problem and received many suggestions.

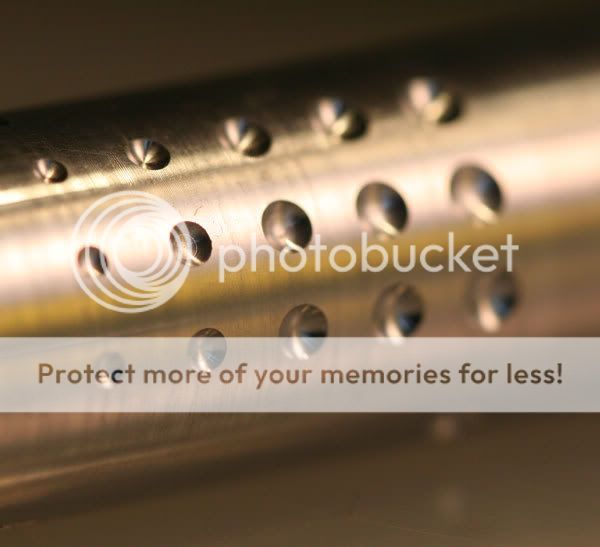

Finally decided to try a very simple, solid drill, a straight flute AlTiN coated carbide 2mm drill, made by SGS:

The good news--it worked like a charm. Cranked the RPMs down to 650 and it went through the TI with no problems.

Until you get to this point in a light, after investing hours and hours on one piece, you just don't realize how difficult even the most simple operations can be. Was I worried that I'd blow the drilling? You bet! And then what? I would have had to start all over again.

Needless to say, it was quite a relief to just drill a simple hole. :lolsign:

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum