LukeA

Flashlight Enthusiast

What about the other one off KD I found? Good? Bad?

You would need 8 of them.

Help Support Candle Power Flashlight Forum

Help Support Candle Power Flashlight Forum

What about the other one off KD I found? Good? Bad?

You would need 8 of them.

Thats out then.

I might just have to make my own drivers!

...

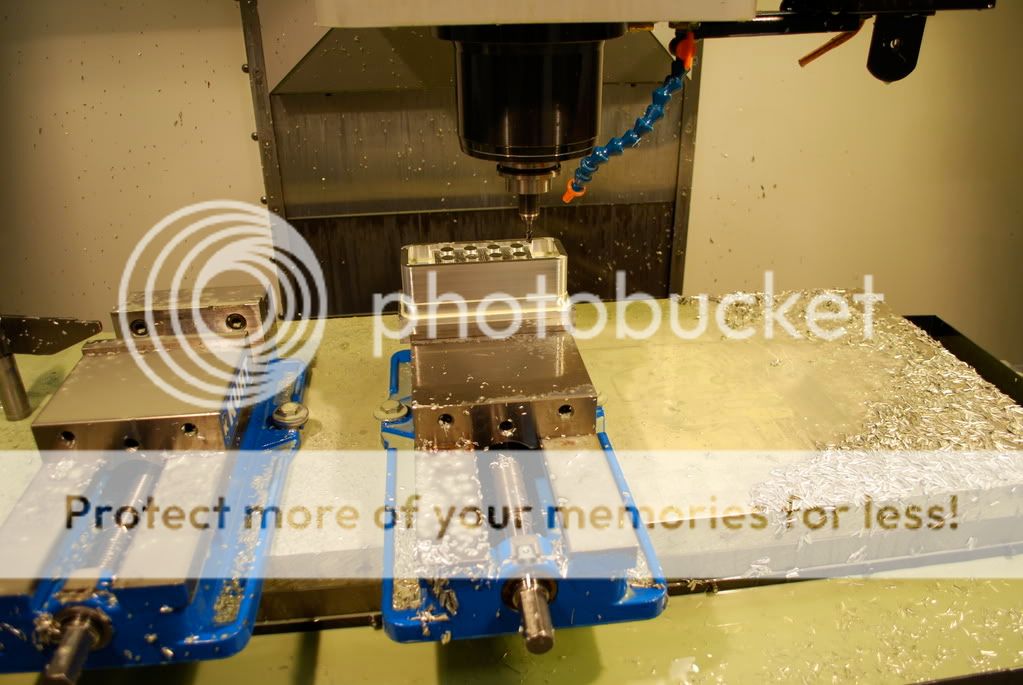

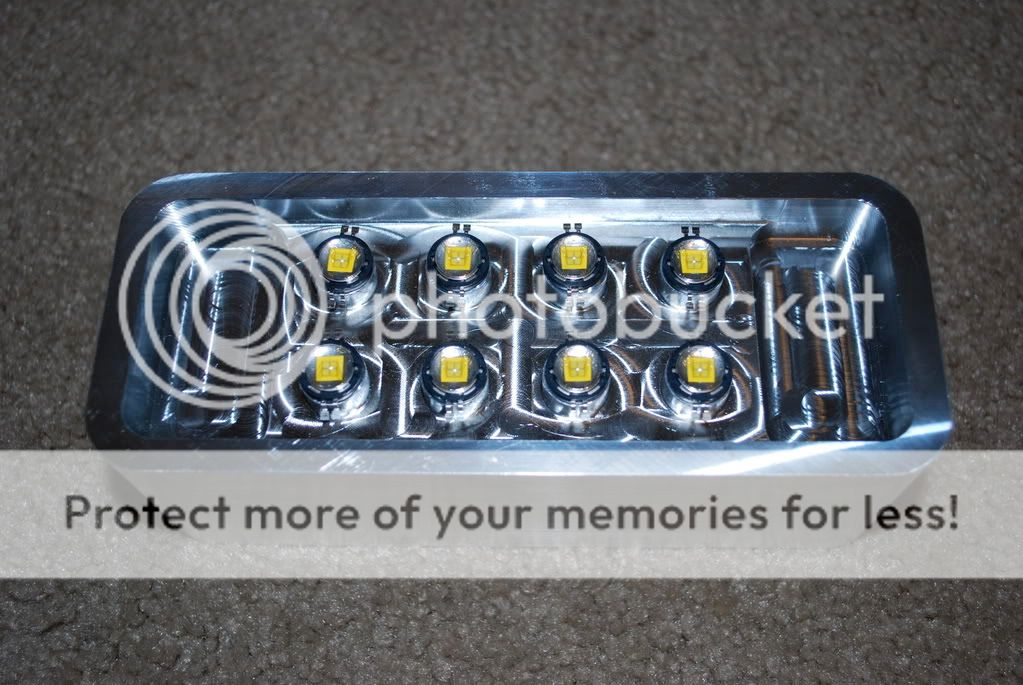

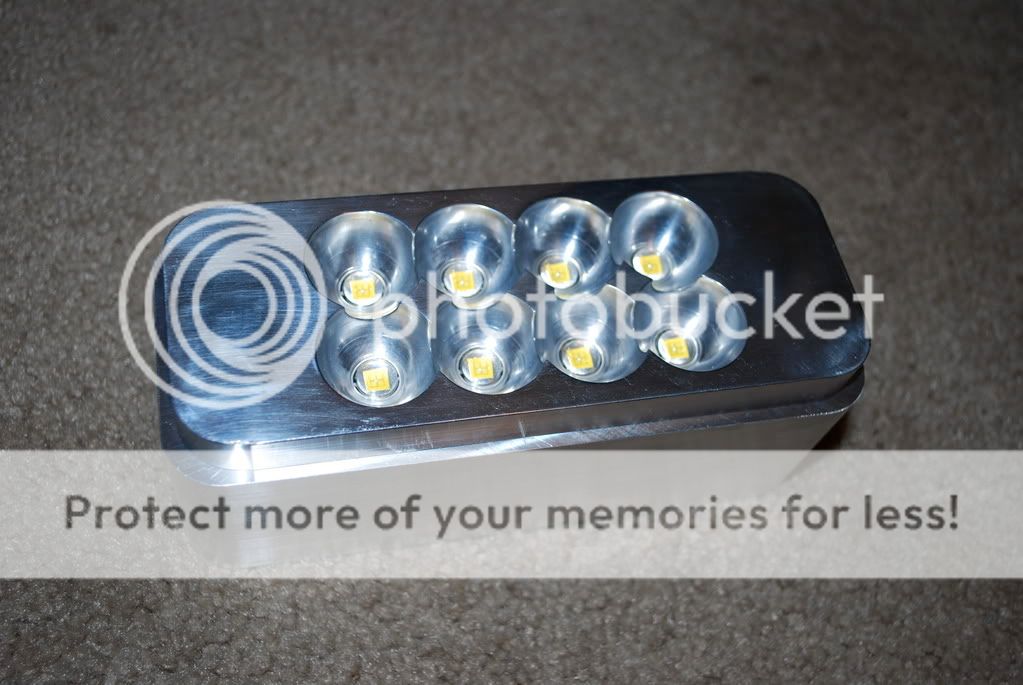

I am a machinist and today I made a reflector cup set up that im hoping will double as some of my heatsinking for the light. I will also be building the rest of the casing and electrical stuff once i can figure out what to drive 8 P7s on a 10-14 volt dc system for my Honda TRX450r (kickstart version).

...

So you are going to power 120 watts of LEDs from your quad? Do you have a 15+ amp alternator installed??

Hmmm. I was planning to but I hadnt thought of running 10ish amps on it. I dont have any sort of higher amp output on it. I was just hoping to run it off the magneto whereas my bike is kick start but I wouldnt be running the stock headlight anymore as my light bar would put out a lot more light. Ill have to see what the light pulls for watts and amps when its finished. Any suggestions for running it on my bike still?

Hmmm. I was planning to but I hadnt thought of running 10ish amps on it. I dont have any sort of higher amp output on it. I was just hoping to run it off the magneto whereas my bike is kick start but I wouldnt be running the stock headlight anymore as my light bar would put out a lot more light. Ill have to see what the light pulls for watts and amps when its finished. Any suggestions for running it on my bike still?Hmmm. I was planning to but I hadnt thought of running 10ish amps on it. I dont have any sort of higher amp output on it. I was just hoping to run it off the magneto whereas my bike is kick start but I wouldnt be running the stock headlight anymore as my light bar would put out a lot more light. Ill have to see what the light pulls for watts and amps when its finished. Any suggestions for running it on my bike still?

It may not be a problem but the total power situation should be considered before getting too far here. You can run the LEDs at lower power, but the drivers may end up being different depending on how it works out. Also the driver efficiency will become important if there is a power limitation.

WOW! That's so cool. I wish we still had a garage, so I could tinker around with this kind of stuff.

**EDIT** I didn't see whether or not you said this, but are going to put any optics in front of those LED's? Or is this light going to be a floodlight? If you were looking for a mix of flood and throw, it would seem logical to me that you would leave the outermost 2 LED's on each side w/o an optic, and optics on the 4 "inside" LED's. You would still have flood, from the outermost LED's, but you could mix and match different types of optics until you were satisfied with the beam pattern.

I got my drivers today!!! Now how do I wire these things?

I got my drivers today!!! Now how do I wire these things?

LukeA? Anyone?

So in that sense, I need to have one on the driver out and 3 on the driver in, right? And then repeat that setup in parallel with another circuit?How to wire the board to run 4 LEDs in series is here (3 are shown, you should add the 4th P7 where there are two.) You wire the one by itself normally but add the others in series before the board.

Cool. I also plan on using an inline fuse and relay in my wiring. What guage wire would you recommend for this stuff? The drivers came with some really tiny stuff.If you're wary about wiring LEDs directly to the battery, it's okay because they're in series and the AMC chips limit the current.

Yes. There are four AMC chips.The boards you have are 1400mA, right?

Cool. I also plan on using an inline fuse and relay in my wiring. What guage wire would you recommend for this stuff? The drivers came with some really tiny stuff.

It sounds like I will want 10-12 g for it, which I kinda figured on 10, but how about internally - in between the LEDs and drivers?

Here it is almost finished. I need to EDM my fins next week as well as make my mounting tabs for the sides, weld them on, and then, an HA3 anodize finish with something like my initials engraved into the top of the light through the anodizing. :twothumbs