Hello, my first post here. I was told to try and get some advice here after posting my build-thread on a bicycle-forum.

I've started building my own 2x20W LED bicycle light, for the purpose of singeltrack riding.

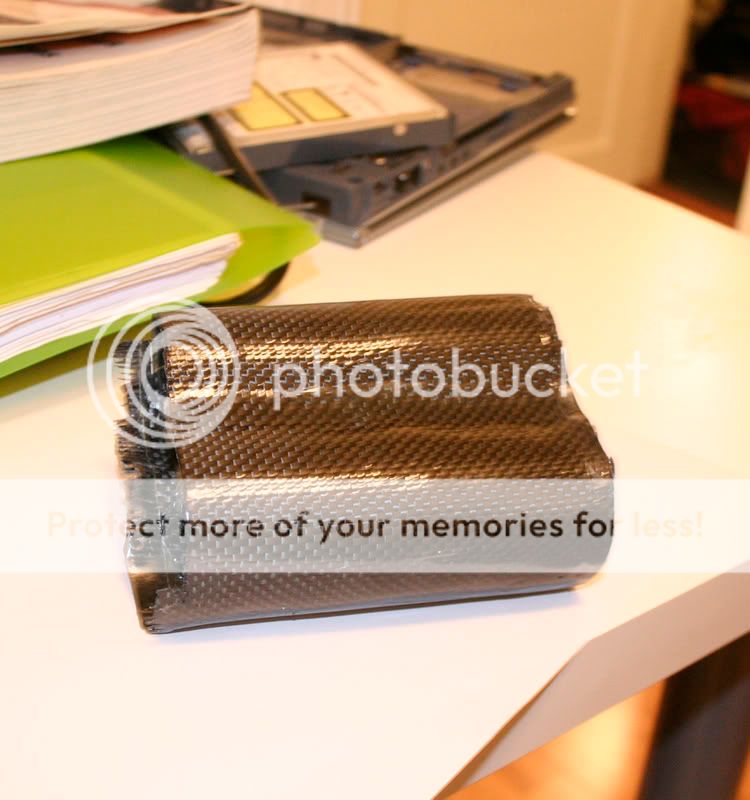

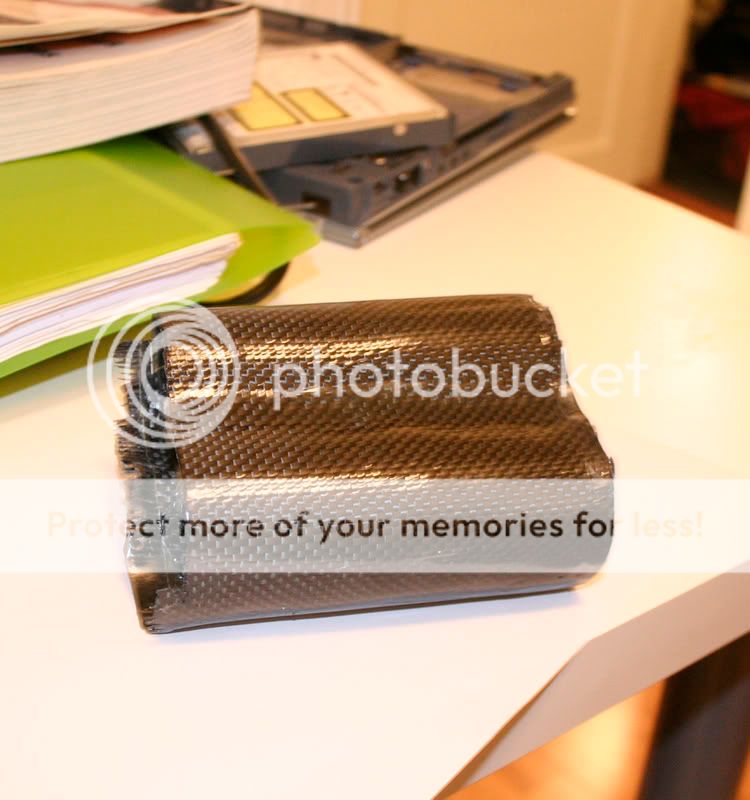

So far, I've built a carbonfiber housing with 2 "barrels" close to each other, with an approx. diameter of 45mm of each barrel.

The LED modules are Edison Opto 20W (bright white, 5000-10000 K)

Battery is Powerizer 5200 mAh 12V LiFe-PO4.

Driver was included from the seller, 1A rated output at 12-14V if I remember correctly.

However, after some building time, wireing and measuring, I've come to a hault. I'm having trouble getting satisfied with the cooling of the modules.

I've tried 2 different aluminium heatsinks, but I'm not happy so far.

I'm a civil engineer by profession, hence, I want to be as conservative as possible when it comes to cooling. My target was staying ~10 C below max rated temp when "standing still" with my bike - meaning there would be virtually NO air traveling across the heatsink, besides the flow generated by the difference in temperature.

So, anyone with some advice/help for me, in regards to:

-Keeping the temperature down

-Fitting all together without too much exposure to "foreign elements" like water & snow

-Lenses with a spreading angel of about 15 degrees.

The max temp rating is about 60 C, and I reach this temperature in about 2-3 minutes of testing.

The likelyhood of standing still for so long during the cold & dark periods of the winter is small, but I want to make sure everything works flawless before bringing my rigg outdoors.

Pictures of the building process and components so far;

Building the housing for the light

Almost done, just need some final cutting, grinding and clearcoat.

3 of the 4 20W LED I purchased for the project

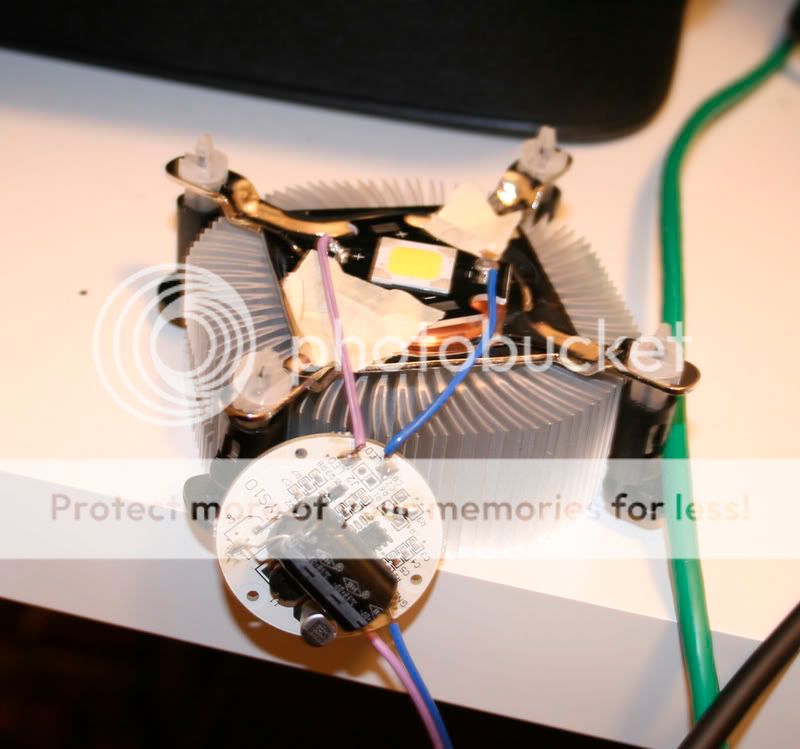

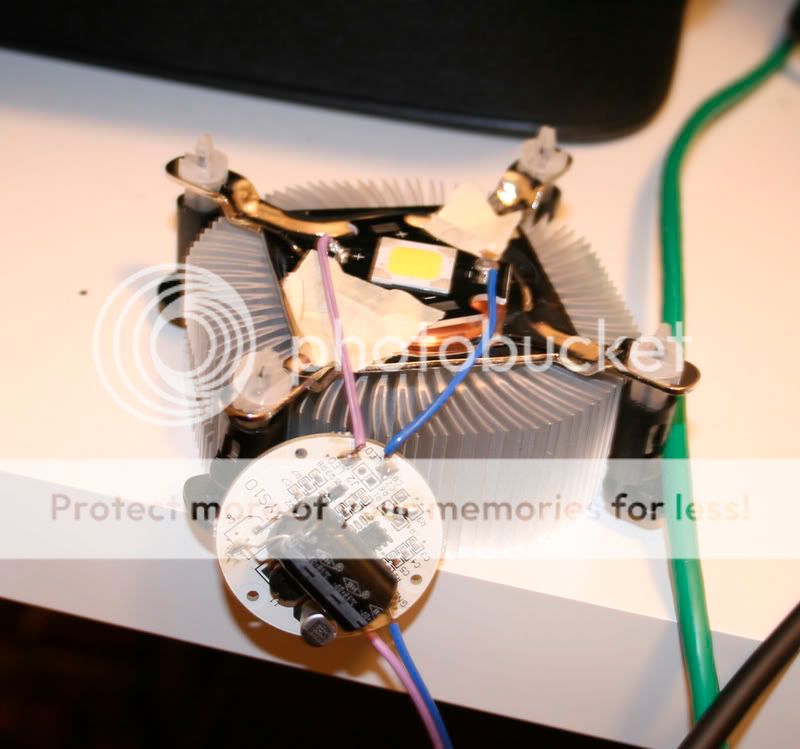

My testbed, an Intel Core 2 Due boxed heatsink with the LED and driver module

Powerizer 5200 mAh 12V LiFePO4 batterypack connected, had to put the light under my couch to protect my eyes

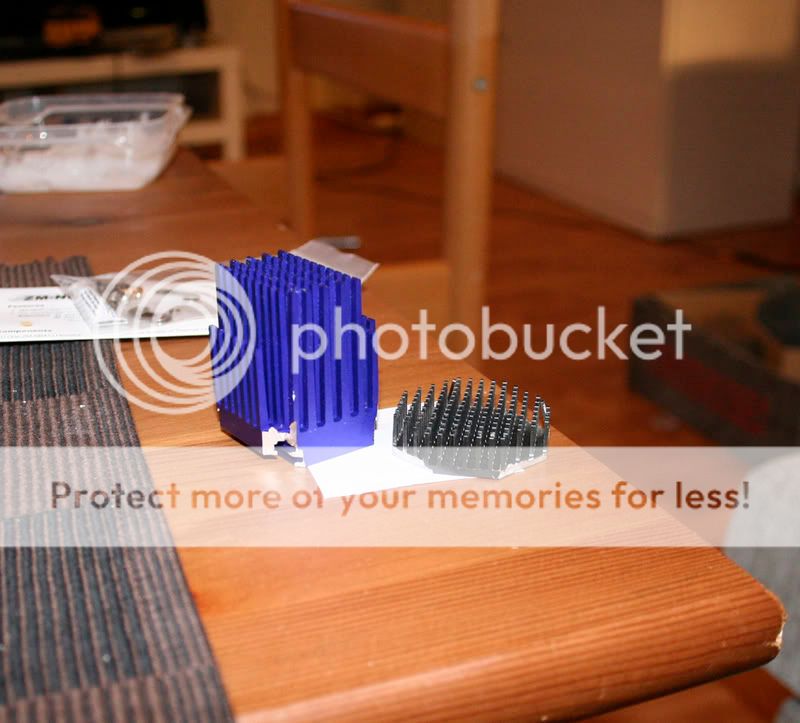

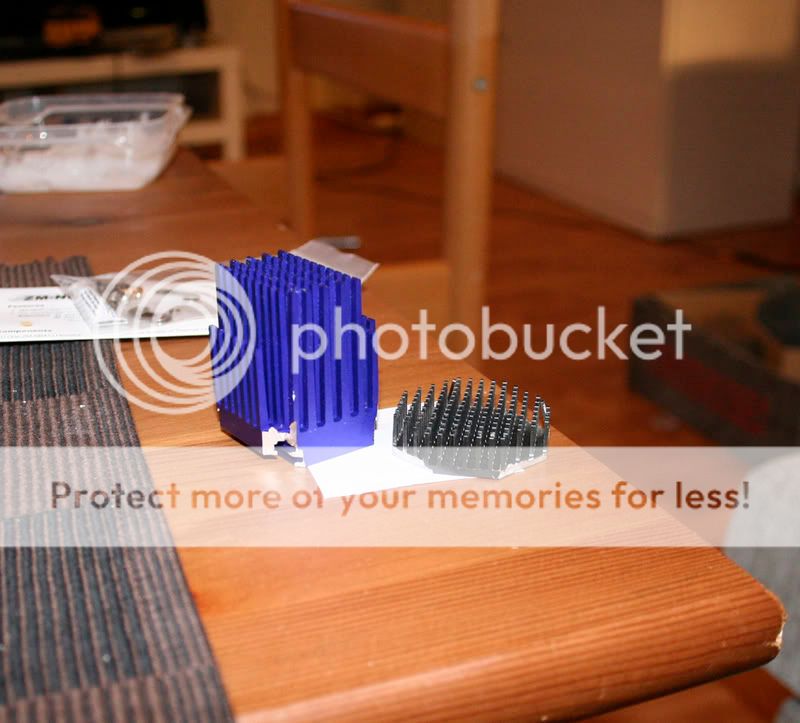

The old and the new heatsink, both intended for computer purposes, the new blue one is a north/southbridge chipset heatsink.

Both cut to fit inside the housing, that's why the corners are cut off.

Best regards,

Andy

I've started building my own 2x20W LED bicycle light, for the purpose of singeltrack riding.

So far, I've built a carbonfiber housing with 2 "barrels" close to each other, with an approx. diameter of 45mm of each barrel.

The LED modules are Edison Opto 20W (bright white, 5000-10000 K)

Battery is Powerizer 5200 mAh 12V LiFe-PO4.

Driver was included from the seller, 1A rated output at 12-14V if I remember correctly.

However, after some building time, wireing and measuring, I've come to a hault. I'm having trouble getting satisfied with the cooling of the modules.

I've tried 2 different aluminium heatsinks, but I'm not happy so far.

I'm a civil engineer by profession, hence, I want to be as conservative as possible when it comes to cooling. My target was staying ~10 C below max rated temp when "standing still" with my bike - meaning there would be virtually NO air traveling across the heatsink, besides the flow generated by the difference in temperature.

So, anyone with some advice/help for me, in regards to:

-Keeping the temperature down

-Fitting all together without too much exposure to "foreign elements" like water & snow

-Lenses with a spreading angel of about 15 degrees.

The max temp rating is about 60 C, and I reach this temperature in about 2-3 minutes of testing.

The likelyhood of standing still for so long during the cold & dark periods of the winter is small, but I want to make sure everything works flawless before bringing my rigg outdoors.

Pictures of the building process and components so far;

Building the housing for the light

Almost done, just need some final cutting, grinding and clearcoat.

3 of the 4 20W LED I purchased for the project

My testbed, an Intel Core 2 Due boxed heatsink with the LED and driver module

Powerizer 5200 mAh 12V LiFePO4 batterypack connected, had to put the light under my couch to protect my eyes

The old and the new heatsink, both intended for computer purposes, the new blue one is a north/southbridge chipset heatsink.

Both cut to fit inside the housing, that's why the corners are cut off.

Best regards,

Andy