StefanFS

Flashlight Enthusiast

This is kind of a pictorial...

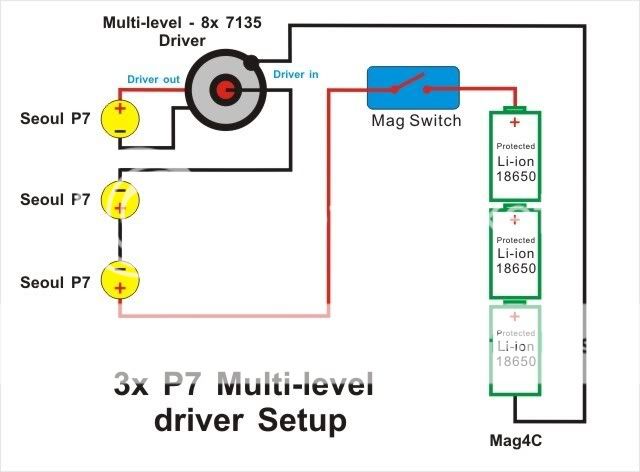

It's based on this very smart driver solution provided by CPF user download:

http://www.candlepowerforums.com/vb/showthread.php?t=201392

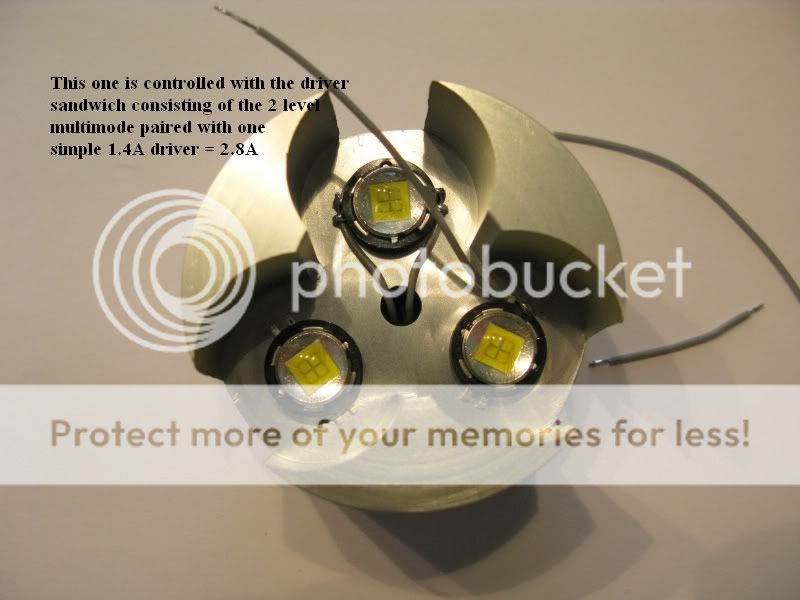

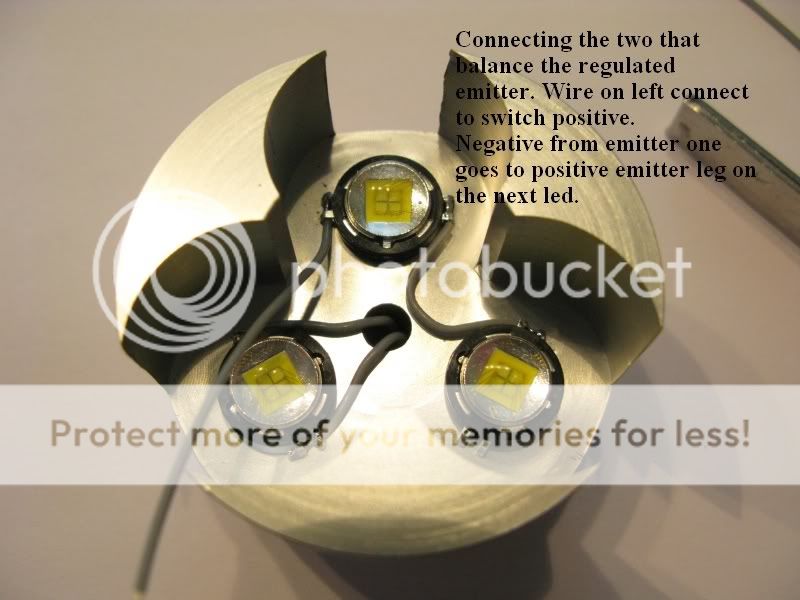

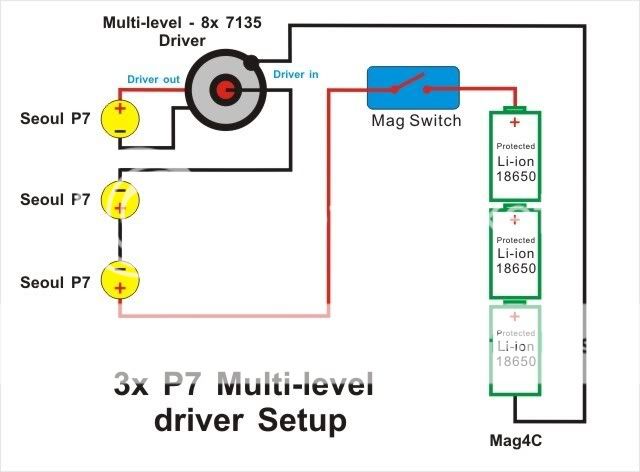

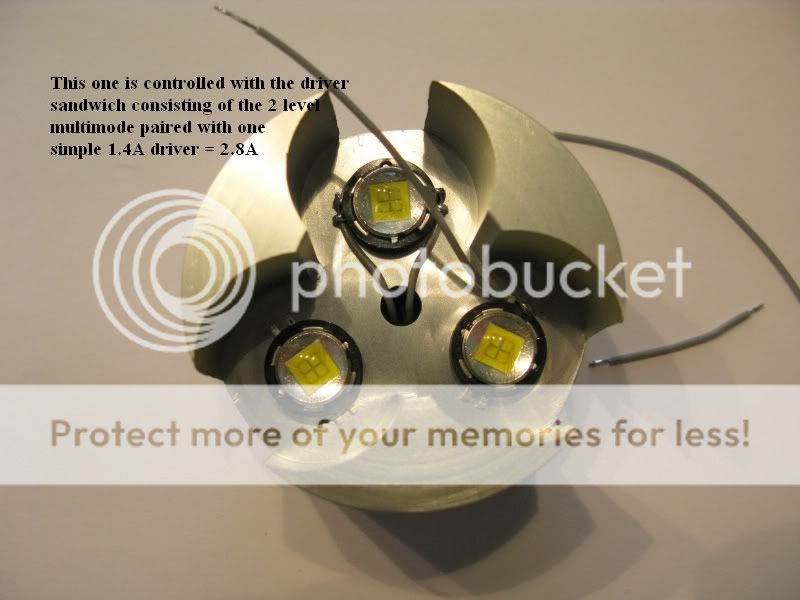

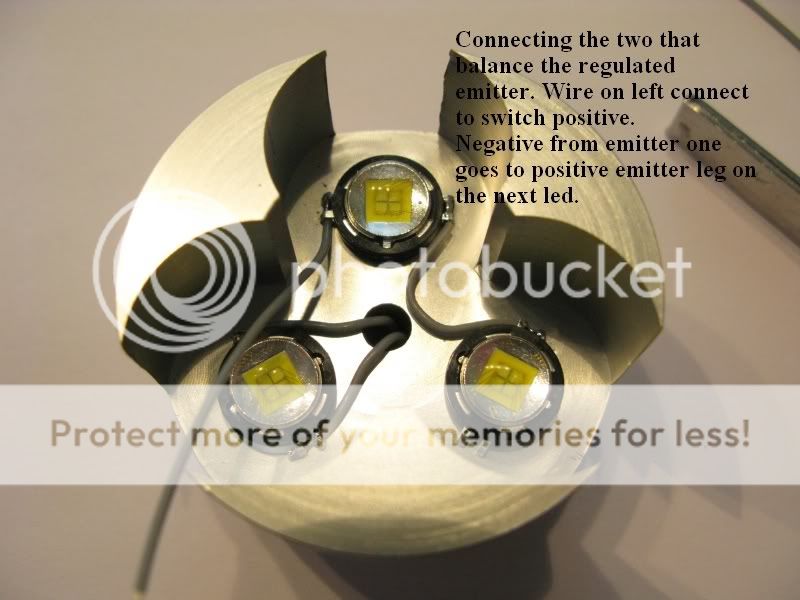

I used 2 level drivers I got from KD, they were 1A with one AMC7135 position unpopulated. I then soldered an additional AMC7135 to that empty socket and had an 1.4A driver. Connections to slave/additional boards are as in my thread below. Total current to each emitter is around 2.8A with D-size LiION.

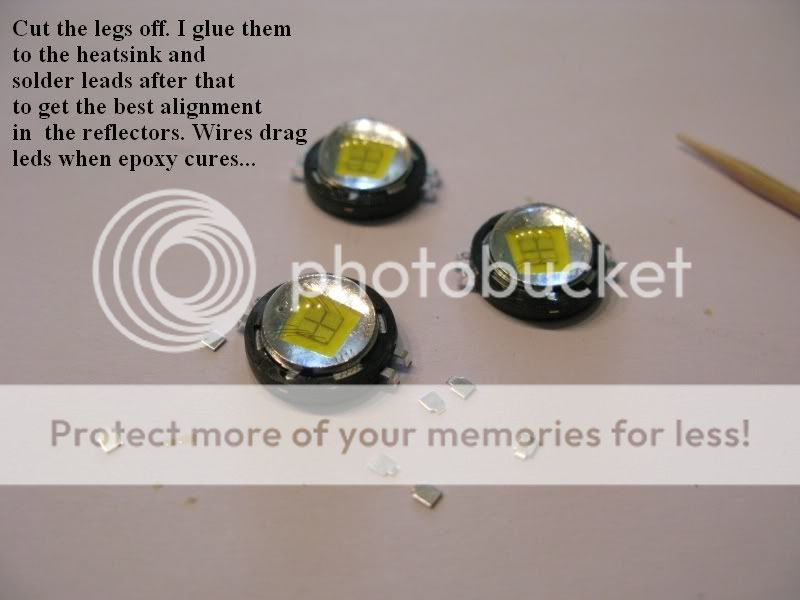

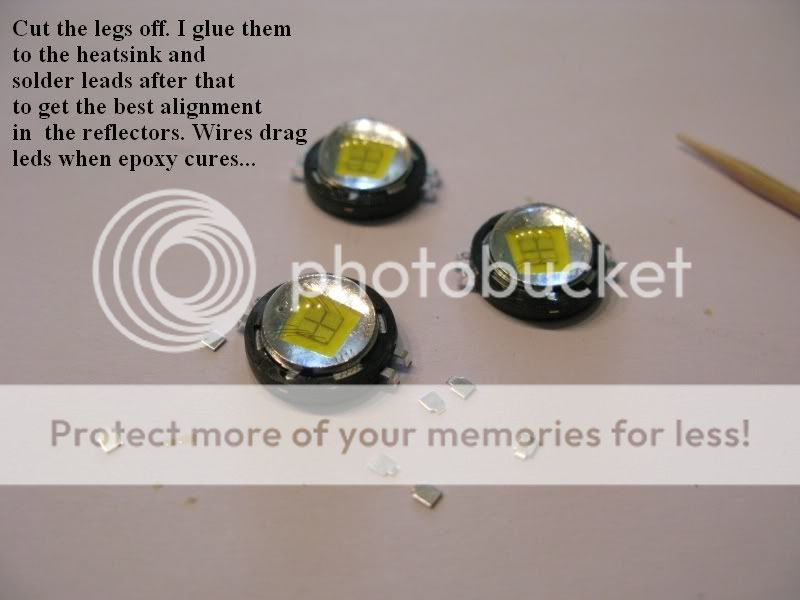

What you need first of all: 3 x SSC P7. I used 1 DSXOI and 2 DSWOI for a nice white beam. The DSXOI was regulated via an AMC7135 based sandwich driver as found here: http://www.candlepowerforums.com/vb/showthread.php?t=195358

I have another with only DSXOI emitters for a cold white shocker.

It all runs from three D-size LiION cells, three 18650 cells or 9 x AA NiMH in fivemega or mdocod cell holders. See links at the end of this post.

Der Wichtels sales thread for the heatsink, reflectors and his buck driver.

http://www.candlepowerforums.com/vb/showthread.php?t=229098

I used a thin plastic circle to fill the space between reflector and the led to press the led down when the epoxy cured. From a platic lid, 0.6 mm or so. Cut with hole punches.

For use with three D-LiION the spring needs to be cut to avoid to much pressure on the cells, they are longer than standard D cells. Same with using three 18650 cells, that requires more radical cutting! Springs are recessed into the tailcap. Tailcaps are deanodized with lye/drain cleaner and hot water. A few grains of powder is enough. Sodium hydroxide is dangerous and will burn skin/eyes, and it fumes. Be careful.

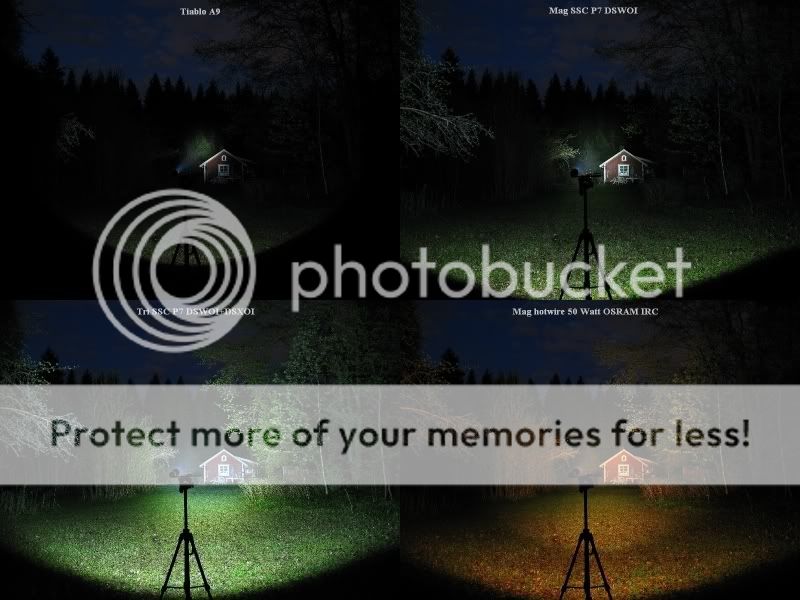

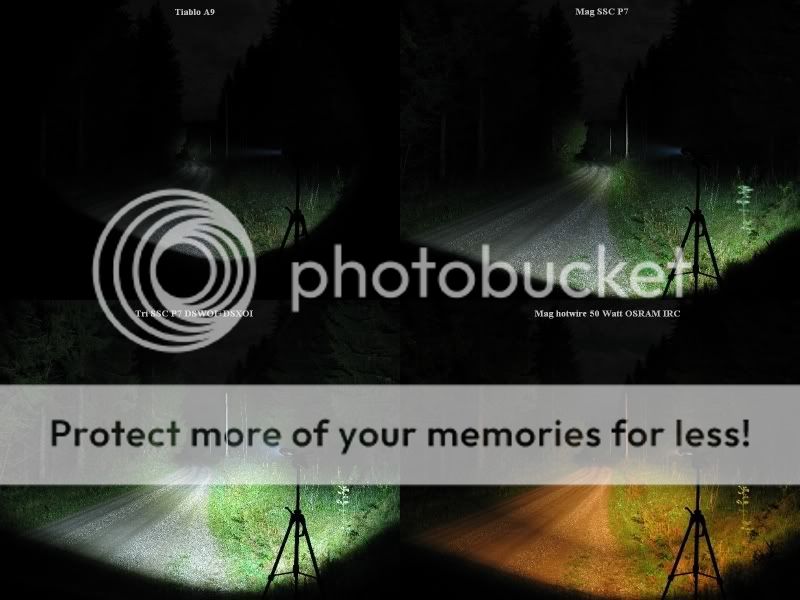

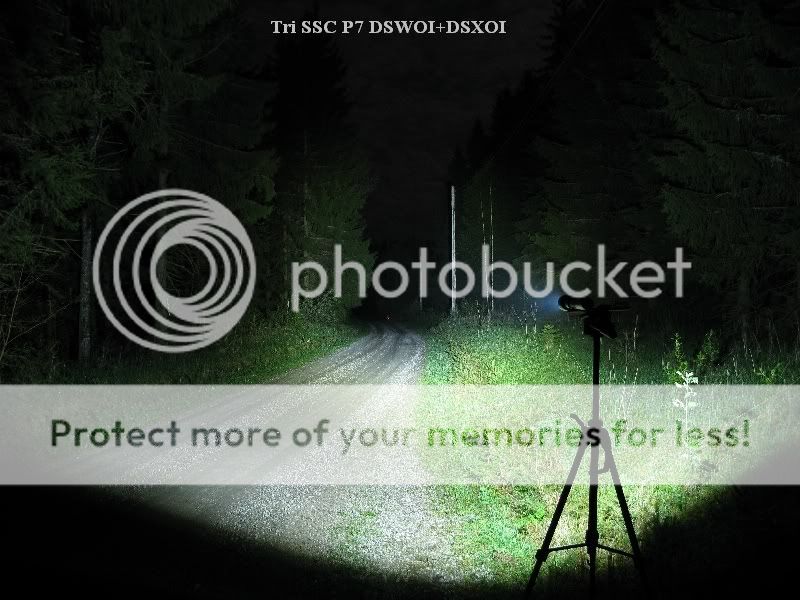

It's bright.

I've been promising outdoor beamshots for some time now. It's coming soon in post #2.

As for performance; I've been using the two lights with 3 x D LiION and have no problems in week three. Mag switches keep up fine and leds do not overheat. They are so bloody bright.

Some cell configs:

http://www.candlepowerforums.com/vb/showthread.php?t=182370

http://www.kaidomain.com/ProductDetails.aspx?ProductId=2751

http://www.kaidomain.com/ProductDetails.aspx?ProductId=2708

I prefer the unproteceted D cells. That entails some responsibility in usage, charge them correctly and do check voltage/capacity. They are good quality industrial cells, but not infallible. It's up to the user to use them right.

Update 2009-05-07

How to adapt the spring an tailcap to use 4 x C-size cells.

I use a length of pvc pipe thats 32 mm OD and have an ID that accepts C NiMH cells, eg. 27 mm.

I cut the spring and deanodize the inner part of the tailcap. I use lye and hot water for this, lye is toxic and highly corrosive, it will burn skin and eyes and it stinks, so be careful. Lye (sodium hydroxide) can be found in drain cleaner other such products.

Cut the spring like this, one little piece at a time until it fits in the tailcap. It's trial and error.

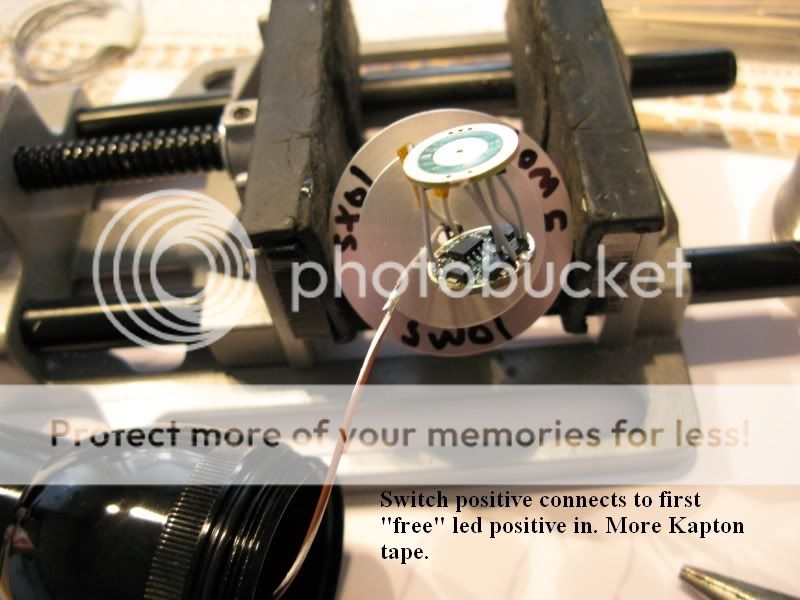

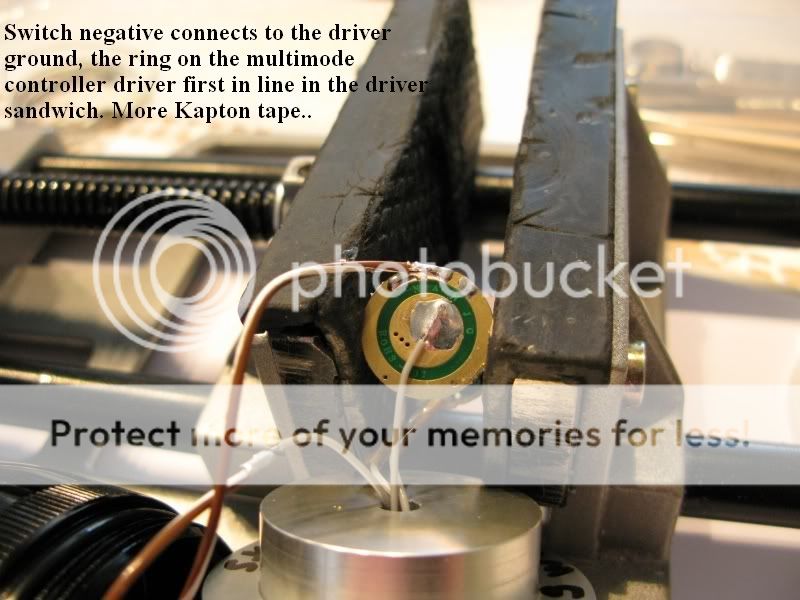

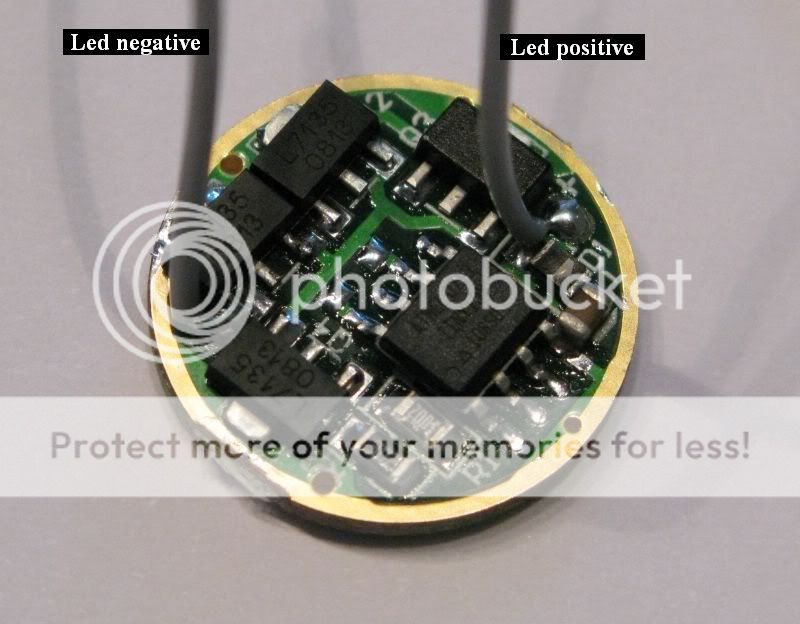

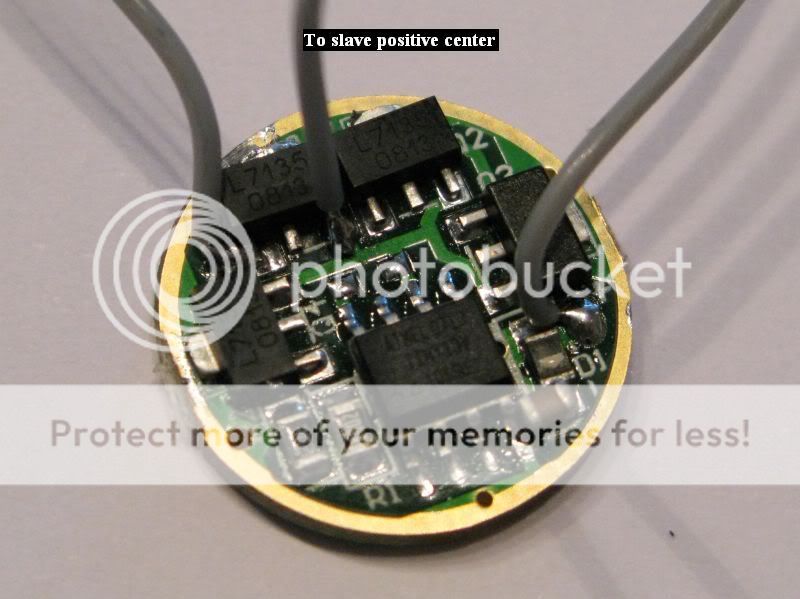

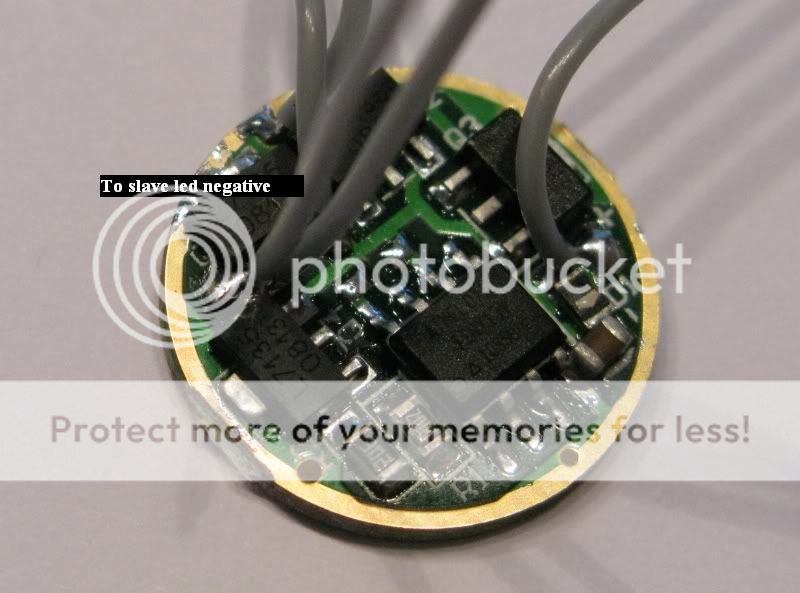

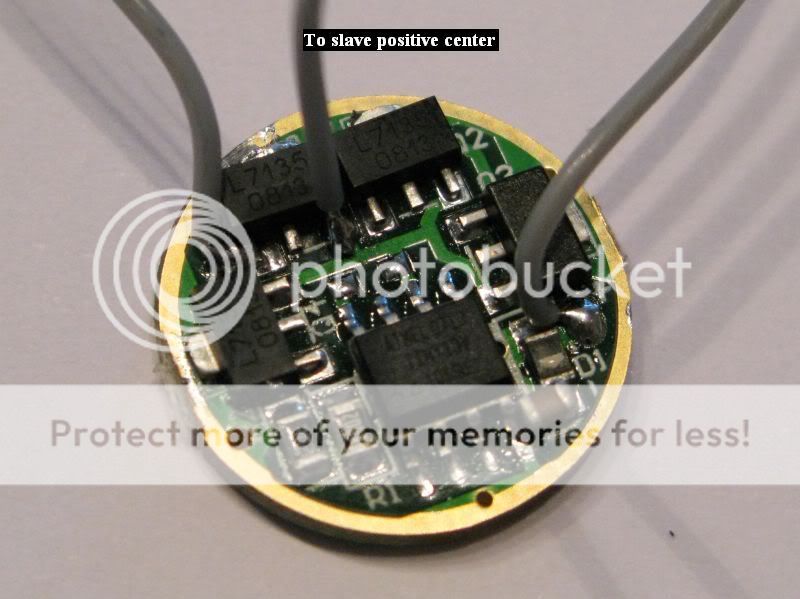

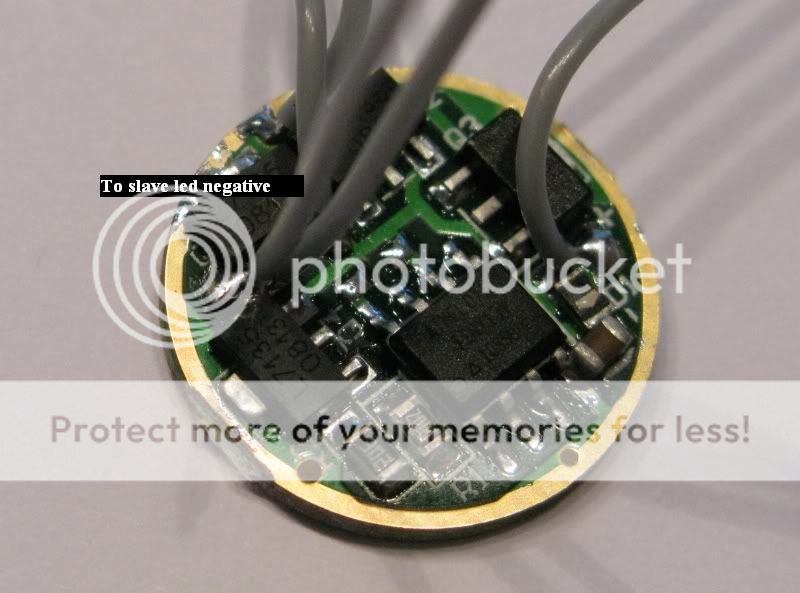

This is how I made the driver for this little adventure!!!!!!

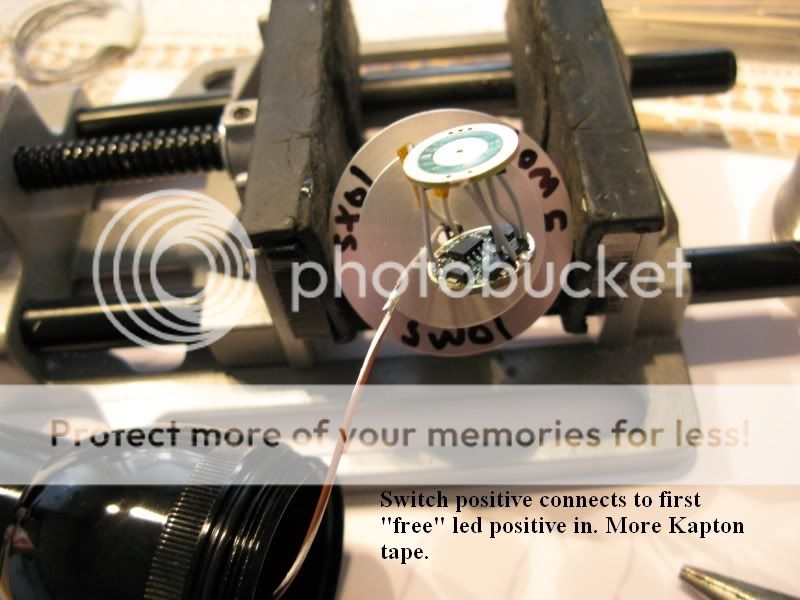

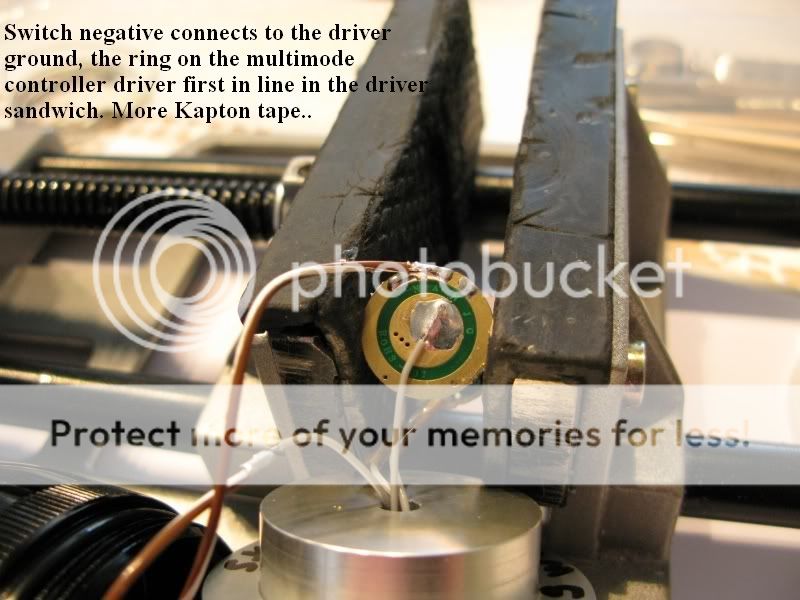

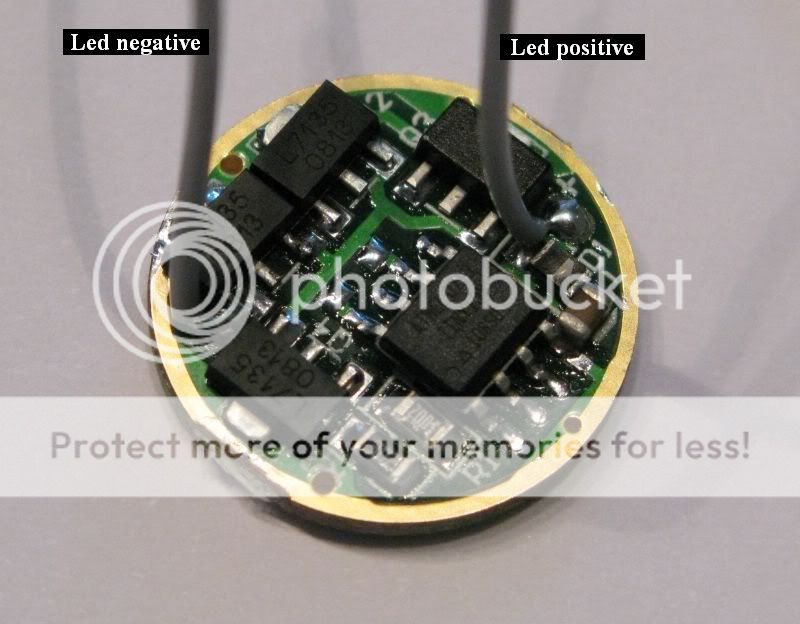

Note that I have popualted an empty space for an additional AMC7135 chip to get 2.8A with just two boards. Even without the additional chip the soldering points are the same. There is at least one more variety of the multimode driver out there, just follow the general rule of connecting as seen here. The last in series AMC735 VDD leg (the one with a trace going to it) on the multimode connects to slave board positive center on all boards I have seen to so far.

The 1A multimode really does give you 1.4A with an additional AMC7135 chip:

Stefan

It's based on this very smart driver solution provided by CPF user download:

http://www.candlepowerforums.com/vb/showthread.php?t=201392

I used 2 level drivers I got from KD, they were 1A with one AMC7135 position unpopulated. I then soldered an additional AMC7135 to that empty socket and had an 1.4A driver. Connections to slave/additional boards are as in my thread below. Total current to each emitter is around 2.8A with D-size LiION.

What you need first of all: 3 x SSC P7. I used 1 DSXOI and 2 DSWOI for a nice white beam. The DSXOI was regulated via an AMC7135 based sandwich driver as found here: http://www.candlepowerforums.com/vb/showthread.php?t=195358

I have another with only DSXOI emitters for a cold white shocker.

It all runs from three D-size LiION cells, three 18650 cells or 9 x AA NiMH in fivemega or mdocod cell holders. See links at the end of this post.

Der Wichtels sales thread for the heatsink, reflectors and his buck driver.

http://www.candlepowerforums.com/vb/showthread.php?t=229098

I used a thin plastic circle to fill the space between reflector and the led to press the led down when the epoxy cured. From a platic lid, 0.6 mm or so. Cut with hole punches.

For use with three D-LiION the spring needs to be cut to avoid to much pressure on the cells, they are longer than standard D cells. Same with using three 18650 cells, that requires more radical cutting! Springs are recessed into the tailcap. Tailcaps are deanodized with lye/drain cleaner and hot water. A few grains of powder is enough. Sodium hydroxide is dangerous and will burn skin/eyes, and it fumes. Be careful.

It's bright.

I've been promising outdoor beamshots for some time now. It's coming soon in post #2.

As for performance; I've been using the two lights with 3 x D LiION and have no problems in week three. Mag switches keep up fine and leds do not overheat. They are so bloody bright.

Some cell configs:

http://www.candlepowerforums.com/vb/showthread.php?t=182370

http://www.kaidomain.com/ProductDetails.aspx?ProductId=2751

http://www.kaidomain.com/ProductDetails.aspx?ProductId=2708

I prefer the unproteceted D cells. That entails some responsibility in usage, charge them correctly and do check voltage/capacity. They are good quality industrial cells, but not infallible. It's up to the user to use them right.

Update 2009-05-07

How to adapt the spring an tailcap to use 4 x C-size cells.

I use a length of pvc pipe thats 32 mm OD and have an ID that accepts C NiMH cells, eg. 27 mm.

I cut the spring and deanodize the inner part of the tailcap. I use lye and hot water for this, lye is toxic and highly corrosive, it will burn skin and eyes and it stinks, so be careful. Lye (sodium hydroxide) can be found in drain cleaner other such products.

Cut the spring like this, one little piece at a time until it fits in the tailcap. It's trial and error.

This is how I made the driver for this little adventure!!!!!!

Note that I have popualted an empty space for an additional AMC7135 chip to get 2.8A with just two boards. Even without the additional chip the soldering points are the same. There is at least one more variety of the multimode driver out there, just follow the general rule of connecting as seen here. The last in series AMC735 VDD leg (the one with a trace going to it) on the multimode connects to slave board positive center on all boards I have seen to so far.

The 1A multimode really does give you 1.4A with an additional AMC7135 chip:

Stefan

Last edited:

I wrote that with my foot in my mouth. I was aware you were using the AMC drivers as opposed to DW's buck driver. I have yet to get my hands on those drivers. I think DX has them back in stock again?

I wrote that with my foot in my mouth. I was aware you were using the AMC drivers as opposed to DW's buck driver. I have yet to get my hands on those drivers. I think DX has them back in stock again? Can't wait for those outdoor beamshots.

Can't wait for those outdoor beamshots.

Just use half of the power of 50W IRC.

Just use half of the power of 50W IRC.  I hope to get around to posting my build and some beam shots as well sometime soon.

I hope to get around to posting my build and some beam shots as well sometime soon.