CPFer F250XL asked me to make a Mag to suit his particular needs. This also gave me a chance to try out an idea for an improved heat sink.

F250XL wanted an SST-50 that is both bright and has decent runtime. He doesn't need levels, so two 4x7135 boards were sandwiched and wired in parallel. The tail cap current with an IMR 26650 at 4.0V is 2.97A.

He needs a lot of spill along with a moderate hot spot. Several metal reflectors were tried but none came close to meeting the requirement, so a standard Mag reflector was lightly sputtered. This worked out very well. The beam actually seems more diffuse than the beam shots suggest but there is a nice soft-edged spot. The plastic lens was replaced with glass, of course.

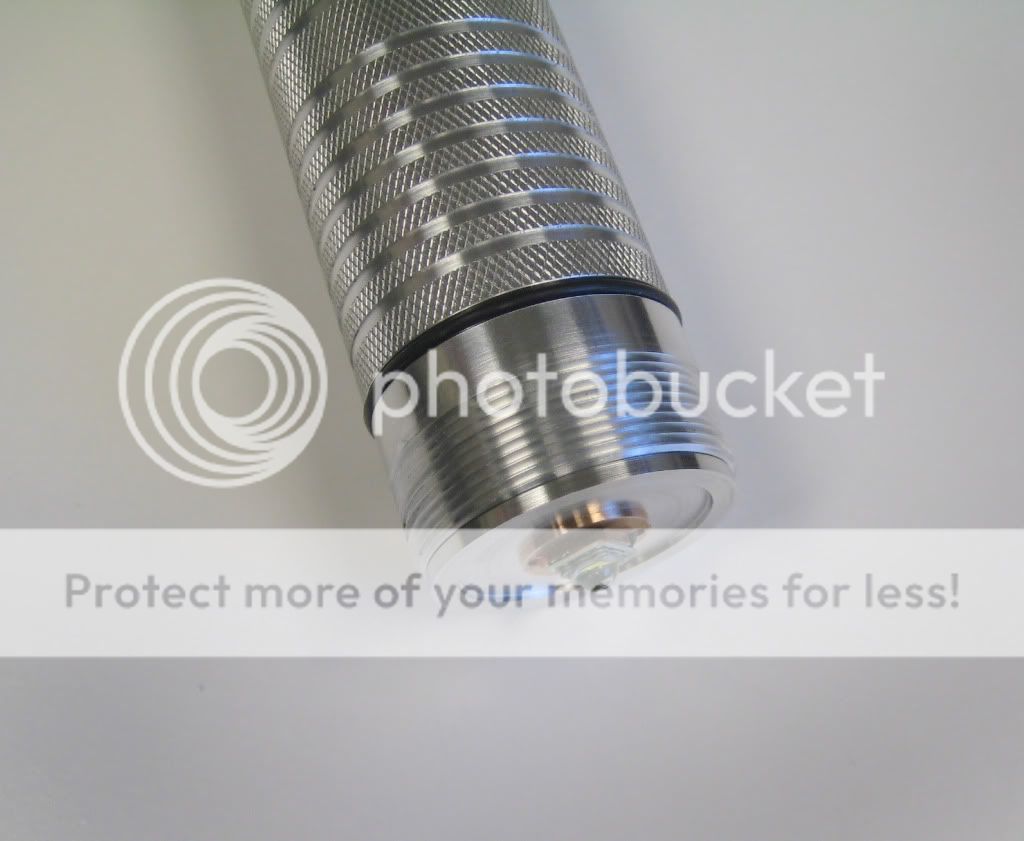

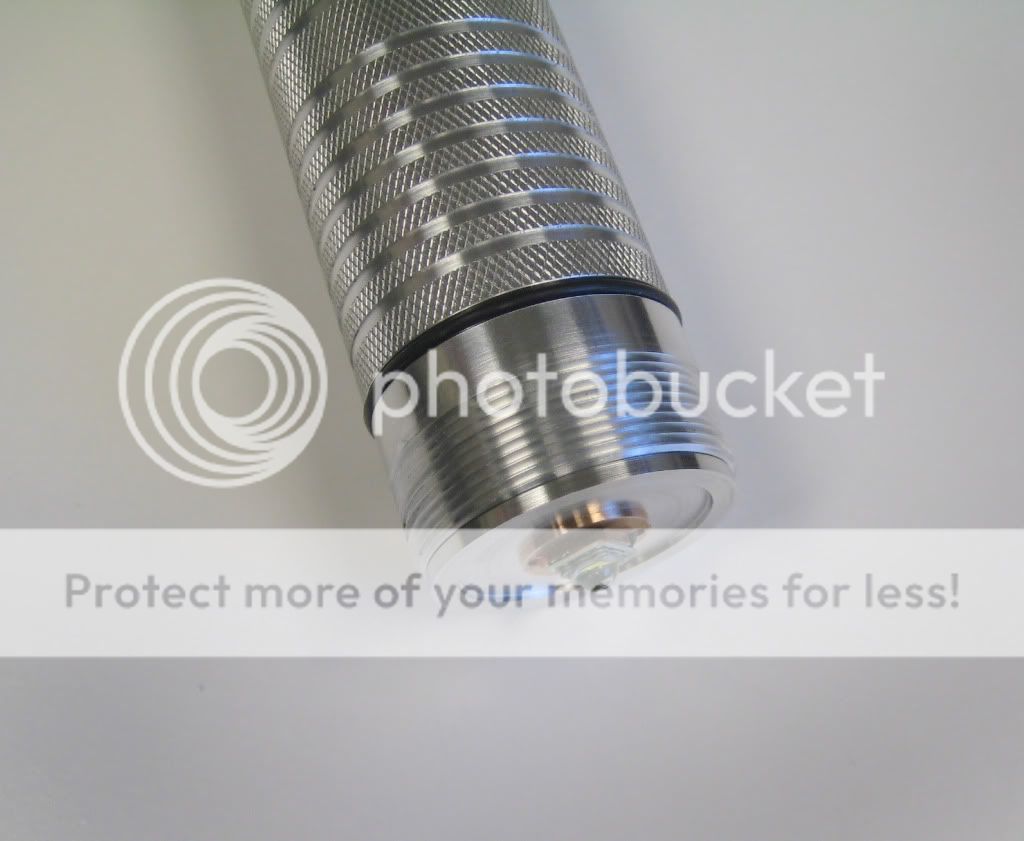

Since it will always run at full tilt, the heat sink is a little bit enhanced. It is quite substantial and has a copper insert to which the SST-50 is reflow soldered. The copper cylinder is pressed into the heat sink. It is tight enough that it is hard to imagine how it would ever come out but the belt-and-suspenders approach made me tap the slug and fasten it with a machine screw from the inside of the heat sink. The bi-metal heat sink seems to be a success and heat dissipation won't be a problem.

There are two PVC battery sleeves. The larger one, for the 26650, has an o-ring around the outside with just enough friction that it stays in the body tube. Thanks for this tip go to darkzero.

The body tube is bored slightly so there is a very smooth finish for the heat sink to contact. The heat sink is just barely a slip fit. If I do say so, I couldn't have hit it better for maximum heat transfer. A few ten-thousandths either way would have made it less satisfactory.

The fins on the head were done a little differently. The usual method is to just run grooves into the head. After doing this, I flattened the top of each fin just a hair to change the profile slightly. Not a huge deal but I like the way it looks.

This project was a lot of fun and I think the new owner will enjoy it, which is the whole point after all!

F250XL wanted an SST-50 that is both bright and has decent runtime. He doesn't need levels, so two 4x7135 boards were sandwiched and wired in parallel. The tail cap current with an IMR 26650 at 4.0V is 2.97A.

He needs a lot of spill along with a moderate hot spot. Several metal reflectors were tried but none came close to meeting the requirement, so a standard Mag reflector was lightly sputtered. This worked out very well. The beam actually seems more diffuse than the beam shots suggest but there is a nice soft-edged spot. The plastic lens was replaced with glass, of course.

Since it will always run at full tilt, the heat sink is a little bit enhanced. It is quite substantial and has a copper insert to which the SST-50 is reflow soldered. The copper cylinder is pressed into the heat sink. It is tight enough that it is hard to imagine how it would ever come out but the belt-and-suspenders approach made me tap the slug and fasten it with a machine screw from the inside of the heat sink. The bi-metal heat sink seems to be a success and heat dissipation won't be a problem.

There are two PVC battery sleeves. The larger one, for the 26650, has an o-ring around the outside with just enough friction that it stays in the body tube. Thanks for this tip go to darkzero.

The body tube is bored slightly so there is a very smooth finish for the heat sink to contact. The heat sink is just barely a slip fit. If I do say so, I couldn't have hit it better for maximum heat transfer. A few ten-thousandths either way would have made it less satisfactory.

The fins on the head were done a little differently. The usual method is to just run grooves into the head. After doing this, I flattened the top of each fin just a hair to change the profile slightly. Not a huge deal but I like the way it looks.

This project was a lot of fun and I think the new owner will enjoy it, which is the whole point after all!

Last edited:

Ready to roll.

Ready to roll.