jslappa

Enlightened

I know I told quite a few people I would update them on the D10/EX10 project I have been working on. After 8 weeks of waiting, I received many of my hosts back from the shop. Instead of cluttering Z's tribute thread, I thought it would be easier to just start a new one. Let's get started then!

So, one of the great things about Cerakote is that it sticks very well to anodized aluminum. The colors all went on smooth, and are now much more durable than before. I had strayed away from the EX10 for a while, focusing mainly on the D10, but these new colors have helped to breathe new life into the EX10 for me. Hope you enjoy! Now for the pics...

Recycled pic, but is shows some of the Nitecore hosts after I disassembled them.

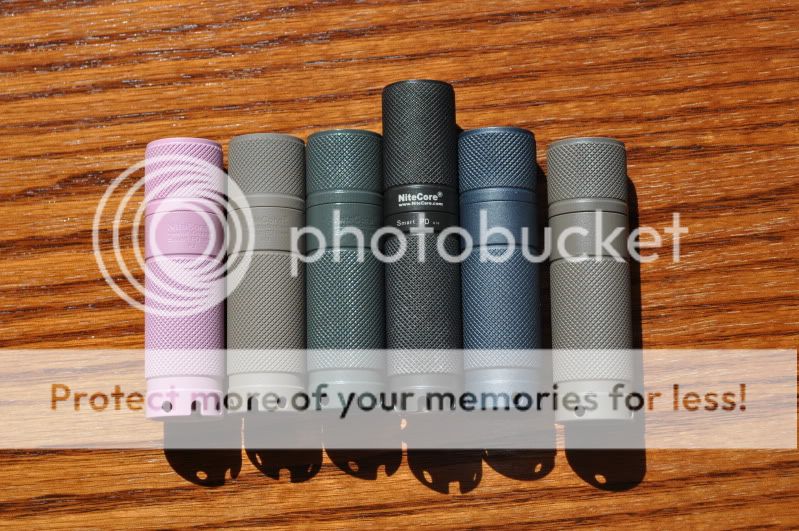

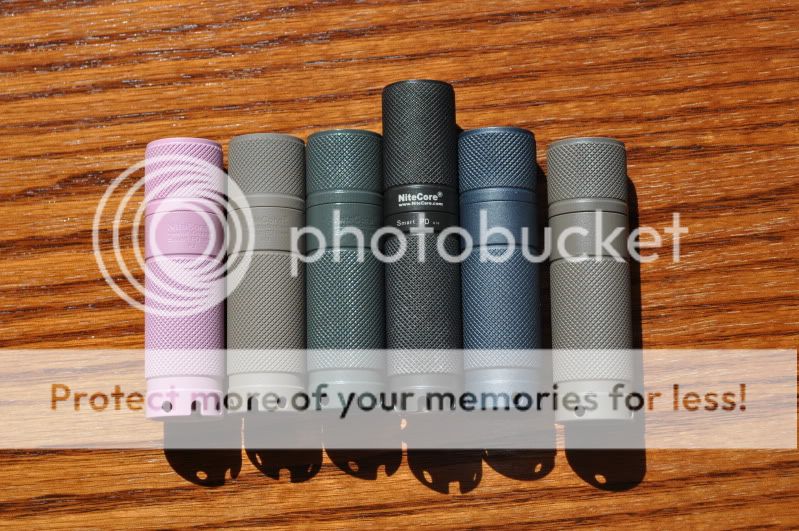

Some of them back from the shop.

D10 in HA, to help you see the color differences.

Fully Assembled

Family Photo

Pink EX10

Blue Titanium

Forest Green

Desert Tan

Coyote Brown

So, one of the great things about Cerakote is that it sticks very well to anodized aluminum. The colors all went on smooth, and are now much more durable than before. I had strayed away from the EX10 for a while, focusing mainly on the D10, but these new colors have helped to breathe new life into the EX10 for me. Hope you enjoy! Now for the pics...

Recycled pic, but is shows some of the Nitecore hosts after I disassembled them.

Some of them back from the shop.

D10 in HA, to help you see the color differences.

Fully Assembled

Family Photo

Pink EX10

Blue Titanium

Forest Green

Desert Tan

Coyote Brown