Lips,

The FT and SFT have a different button (shorter) and the main body's stem has been shortened, reducing the travel required to get from low to high. The main bodys look the same but would not measure the same in total height. Springs and the PCB are the same in both switches. As you mentioned, the FT and SFT have buttons that are so short that they do not have an O-ring retainer and will come out freely when the tail cap is removed.

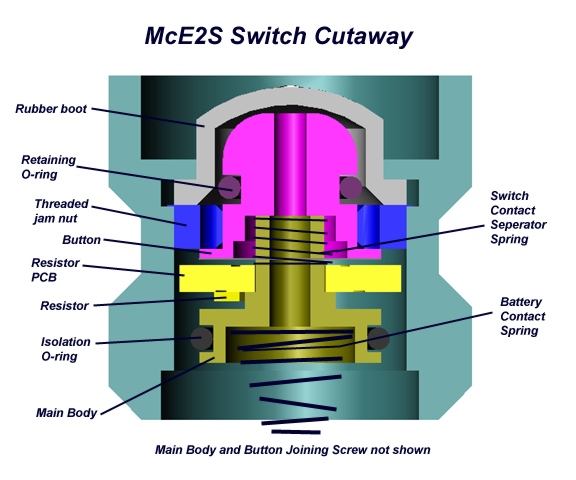

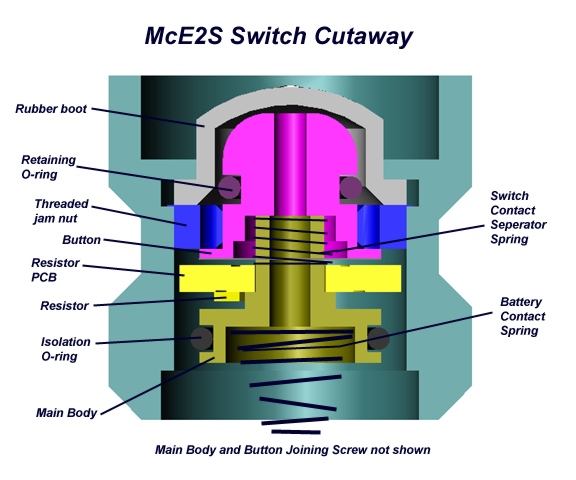

When you push the switch in, you are compressing the battery contact spring at all times and the further you push the more resistance and effort is required. Once you push the switch far enough for the resistor PCB to contact the rear lip of the battery tube, you have achieved low output. further depression of the button continues to compress the contact spring but now you are also pushing the main body through the resistor PCB (it's now stopped on the battery tube) and you are compressing the switch contact seperator spring as well (additional effort). The combination of displacement and additional force required add to achieve a tactile sense of where you are and help to keep from going to far and hitting the high when you only want low.

There are variations from switch to switch and light to light and person to person which make some of these switches very acceptable to the user and for others, too much of an effort for prolonged use in momentary. /ubbthreads/images/graemlins/icon3.gif The mechanics are really rather simple but it sure took me a bunch of head scratching to come up with the design from the get go. /ubbthreads/images/graemlins/blush.gif The springs as well as dimensions can be tweaked by the end user for fine tuning. Reaming out the bore in the jam nut and removing the retaining O-ring can often enhance the ease of activation as well.