Justin Case

Flashlight Enthusiast

- Joined

- Mar 19, 2008

- Messages

- 3,797

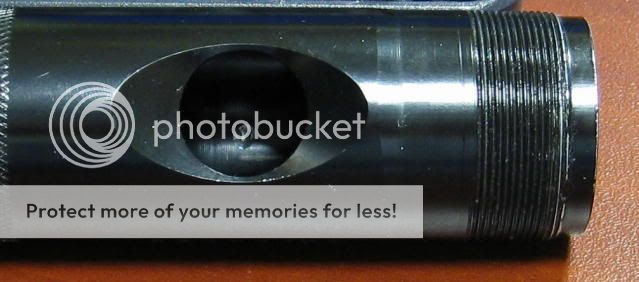

I have one that separated its two halves under spring pressure when it slid out the top of the CMag tube. I think I found all of the parts, but can't be sure. But I'm having trouble determining correct reassembly of the jigsaw pieces.

Anyone have a recipe or exploded parts diagram showing how the pieces go together in a pre-2001 C Mag switch (the Mags without the letter "C" in the serial number)?

Does the switch open and close a contact for the battery + or for ground?

Thanks.

Anyone have a recipe or exploded parts diagram showing how the pieces go together in a pre-2001 C Mag switch (the Mags without the letter "C" in the serial number)?

Does the switch open and close a contact for the battery + or for ground?

Thanks.