CampingLED

Enlightened

We all want batteries that have the lowest internal resistance, highest capacity, protection, LSD / no SD, small, etc.

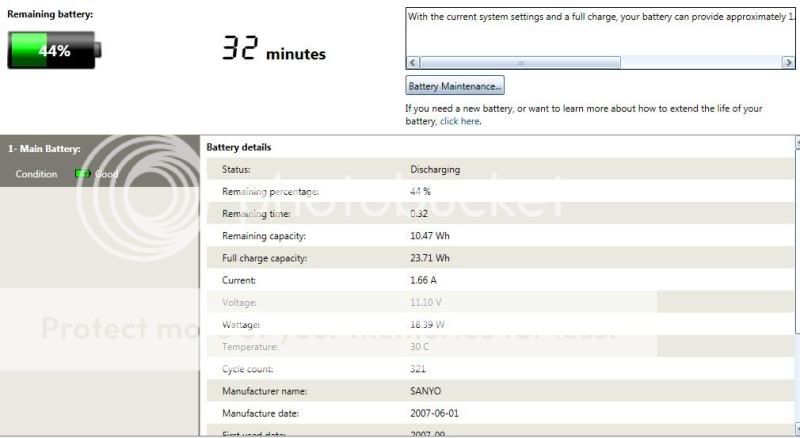

What we also need are batteries that can provide real time wireless info to external devices. This is not impossible. Think of a battery with a blue tooth (or other wireless connetion) to your PC or phone that provides real time info on:

- Current drawn,

- Current voltage,

- Capacity left,

- Low capacity warning,

- Average runtime left before protection cuts in,

- For car batteries, water level per cell,

- etc.

The info will only be transmitted while current draw is detected. Think of the endless review possibilities that will be in most of our hands. With appropriate s/w we can get real time graphs on our PCs and know how our lights are performing on the battery side.

I love to dream, maybe 5 to 20 years from now??? :sigh:

What we also need are batteries that can provide real time wireless info to external devices. This is not impossible. Think of a battery with a blue tooth (or other wireless connetion) to your PC or phone that provides real time info on:

- Current drawn,

- Current voltage,

- Capacity left,

- Low capacity warning,

- Average runtime left before protection cuts in,

- For car batteries, water level per cell,

- etc.

The info will only be transmitted while current draw is detected. Think of the endless review possibilities that will be in most of our hands. With appropriate s/w we can get real time graphs on our PCs and know how our lights are performing on the battery side.

I love to dream, maybe 5 to 20 years from now??? :sigh:

SUDDEN DEATH!!! Not because of the light, but because the protection kicks in without warning. Some of these lights are highly acclaimed tactical lights.

SUDDEN DEATH!!! Not because of the light, but because the protection kicks in without warning. Some of these lights are highly acclaimed tactical lights.