Thanks fellas. Great info here & is very helpful for me. Although I've learned alot just reading on the net the most valuable information I get from you guys here.

I do remember Brian saying positive inserts are most recommended for smaller, less powerful machines. Wish I had remembered that when buying my last two holders.

BTW, thanks for the holders, they look great! :thumbsup:

I started off using the common generic 1/2" 5 piece indexable set using TCMT 31.51 inserts. I wanted to get something better now.

Here's what I currently use the most:

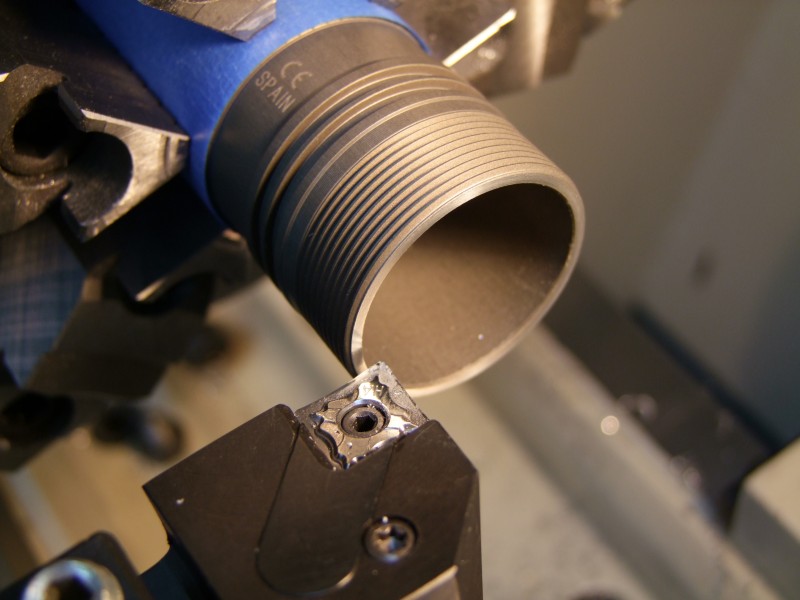

I picked up MTGNR & MTJNR 08 2A holders. These use 1/4" IC inserts & have a 7° neg rake. The MTGN has a 0° lead angle so I got the MTJN for facing. I had these in mind cause the TNMG would give me 6 cutting sides & that would be more economical.

Didn't realize there wasn't a very good selection of inserts available for TNMG 1/4" IC. I started off with a Seco TNMG 222 MF1. Didn't like how they cut too much because of the larger corner radius. Then I got a Valenite 221 F1 & Valenite 222 F3 to try. The Valenite 221 with fine chip breaker does ok with alumn but I only get a nice finish when using lots of cutting fluid & when facing some drill rod, towards the center the finish was poor as if there was chatter? The Valenite 222 F3 has a higher positive angle so I thought it might work better. A little bit better but not all that much. I don't like the larger corner radius. I was planning on getting a TNMP 221 to try but I don't think I will now.

First thing I noticed was the TNMG inserts being negative they didn't feel as sharp as the TCMT inserts. I also noticed that the TCMT uncoated carbide seems to work better with alumn over the Tin coated carbide. With the coated TNMG inserts I seem to get alot of BUEing (is that the correct word?).

Based on the information you guys have given me I'm going to go back to using positive inserts & I'd like to stick with the 3/8" IC size & no larger. I'd like to get something with a bit of a neg lead angle so I can use the same holder for turning & facing. With the 0° lead angle I have now on the MTGNR & AR they're ok when turning a 90° shoulder but it just doesn't feel right to me using them for facing as the entire side of the edge is touching the workpiece. I know I can always turn the tool post when facing but I want to avoid having to make any unecesary adjustments during the job.

I'll be working mostly with alumn, brass & copper so I want to find an insert that will work best for me. The inserts I was looking at are H01 with an AK chip breaker & mirror face. They also have the inserts available in CC & TC shape. I've been planning on sticking with the triangle shape since I have a smaller machine plus I'll get three cutting edges. Looks like my choice now is to either get a STJCR/L which have a 3° neg lead angle & use 32.5 inserts but I will have to get them milled to fit my holder. Or get SCLCR/L which have 5° neg lead angle & use 3/8" IC inserts but I won't have to mill them to fit. I'm leaning toward the SCLC 08 3As, oh well, I 'll have to live with just two cutting sides per insert.

I just thought the 80° diamond shape might not work as well for my little maching but my boring bars use CCMT inserts & they seem to work rather well. In the mean time I'm going to go back to my generic 1/2" holders with uncoated carbide as I wait for my new holder & inserts to come. I'll be throwing the Dorian MTGNR & MTJNR 08 2A holders with inserts on ebay unless anyone here might want them. If yes send me a PM or email.

Anymore advice or recommendations is well appreciated! Sorry for asking all the stupid questions but I'm eager to learn & I'm not afraid to ask so please bare with me as I learn.

I feel more comfortable asking you guys here rather than on the machining forums. Thanks again. :twothumbs

BTW, thanks for the holders, they look great! :thumbsup:

BTW, thanks for the holders, they look great! :thumbsup: