I understand what you are saying, but quite frankly it does have to do with energy density of the full cell, and how much delithiation of the cathode you need to reach that energy. If you charge one of the AW IMR cells 18650 cells to the same energy as an A123 18650, the exothermic reactions you speak of (the ones that liberate oxygen from the cathode) cannot occur either.

The point is the exothermic reactions can't occur with a LiFePO4 cell regardless of what you do. That's the definition of inherent safety, and that's the big selling point for me here. You can design in all the protection circuitry you want but fact is sometimes circuits fail. I prefer to use a cell which won't self disassemble if something goes seriously wrong with the protection circuitry.

Honestly, yours is the first statement I've heard, ever, saying that lower energy density is the reason LiFePO4 is safer. This is especially puzzling because there seems to be some overlap in energy density between the IMR cells and LiFePO4, and yet LiFePO4 is still safer. I'd love for a CE to chime in about this because I always thought the sole reason LiFePO4 was safer was the chemistry.

With respect to EVs, only the Chinese are using LiFePO4 for EVs, and not without significant safety issues. Want to see a demonstration of the "inherent safety" of LiFePO4 in EVs,

look here. My point in showing that link is not to say that LiFePO4 is NOT safe, but rather to show that LiFePO4 CAN fail in an unsafe manner. Too many people think that just because they have a LiFePO4 battery that nothing can go wrong.

I did a

little research. Basically, if you read the article, it seems shoddy workmanship and inattention to detail was the cause of the fire. To quote from the article:

"The report adds that the battery cells on the car, made by Zhejiang Wanxiang Group, themselves were not responsible for the accident, but were employed improperly for an electric taxicab."

If anything, this is yet another testament to the inherent safety of LiFePO4. Despite the abuse given to these cells, they failed to explode. Due to the huge current

any EV battery puts out a fire can certainly start. But there was no explosion like there might have been if LiCoO2 had been used.

LiFePO4 has its place in the world of lithium-ion. I think that it makes sense for large, stationary batteries, which is actually the direction that A123 is moving. There is a reason that no commercially available hybrid, plug-in hybrid or EV uses A123 cells...the performance just is not as good as can be achieve with other chemistries.

They also make sense for people like me who are looking for a cell they can build into a project, then not think about it for the next decade or more, or worry about it blowing up if something in the charging circuit fails.

As for automotive uses, maybe having to assemble a few thousand 26650 cells into a battery pack is the reason A123's cells aren't being used? If A123 Systems were smart, they would start making larger single cells so that a few dozen could be used for an EV battery pack. Energy density isn't an issue here because "safer" conventional Li-Ion cells, such as the LG Chem cells being used in the Volt, also have lower energy density. To the best of my knowledge nobody is using or planning to use higher energy density LiCoO2 in EVs.

Possible, but you have to remember that all lithium-ion cells still use the same anode (negative electrode), and a lot of degradation in lithium-ion cells occurs at that electrode as well. LiFePO4 does not do anything to stop degradation mechanisms at the negative electrode that contribute to cycle and calendar life degradation.

I don't have a good answer for you other than to say that the primary degradation mechanism likely occurs at the cathode. If anode degradation were important, the A123 System cells would suffer regular annual capacity loss, and yet tests show they don't. Maybe anode degradation comes into play over a time span of decades?

Then you have had very, very bad luck my friend.

Me and everyone else I've known. It's more like you've either had exceptionally good luck, or you've given your cells far better treatment than most people, including myself, ever would. Basically, I expect a rechargeable cell to be ready to use when I want to use it, even if it's been sitting in a drawer for years. That means it either retained a charge, or retained the ability to be charged to near new capacity, perhaps after a few break-in cycles. So far, only NiCd, LSD NiMH, and LiFePO4 have been able to cope with those demands. I've seen all other types of rechargeable lithiums degrade. Same thing with most conventional NiMH.

If you are buying consumer electronics from well known companies, you can be pretty certain that the cells are of reasonable quality and being charged/discharged correctly. However, I must admit that there has been a big push to maximize the capacity of cells for consumer electronics, and often this is done at the detriment of cycle life.

You hit the nail on the head as to both why LiFePO4 isn't used in consumer electronics, and why also it seems that new devices have worse cycle life than older ones.

You are right, it is a shame that LiFePO4 doesn't have a higher density. But I stand by my statement for this forum, except perhaps I should have qualified that I was talking about flashlights in particular. I do think that LiFePO4 has a place in the family of lithium-ion, but there are few applications that can utilize its niche advantages.

If I were wrong, A123 Systems would be taking over the world. As it stands,

they are struggling to say the least. And they will continue to struggle until they can move beyond LiFePO4.

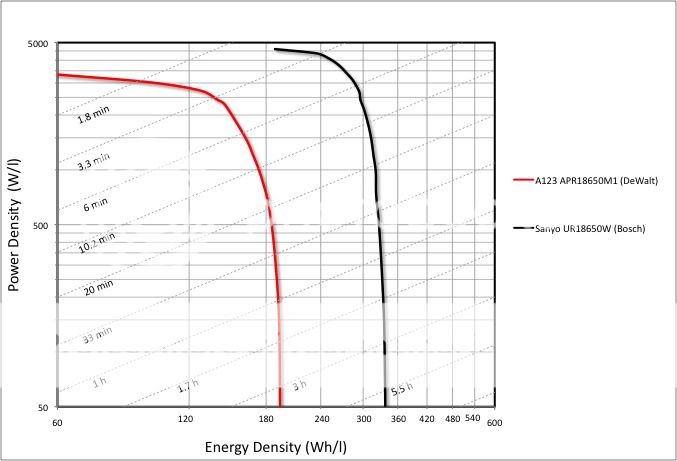

Isn't A123 Systems doing research which they claim would eventually increase the energy density of LiFePO4 by something like a factor of four? In any case, A123 Systems signature product

is their LiFePO4 cell. IMO they need to focus on improving that, not become yet another player manufacturing the other types of lithium cells. Also, if you ask me, I'd say within a decade chemical cells of all types will be obsolete as ultracapacitors outpace them in both energy and power density.